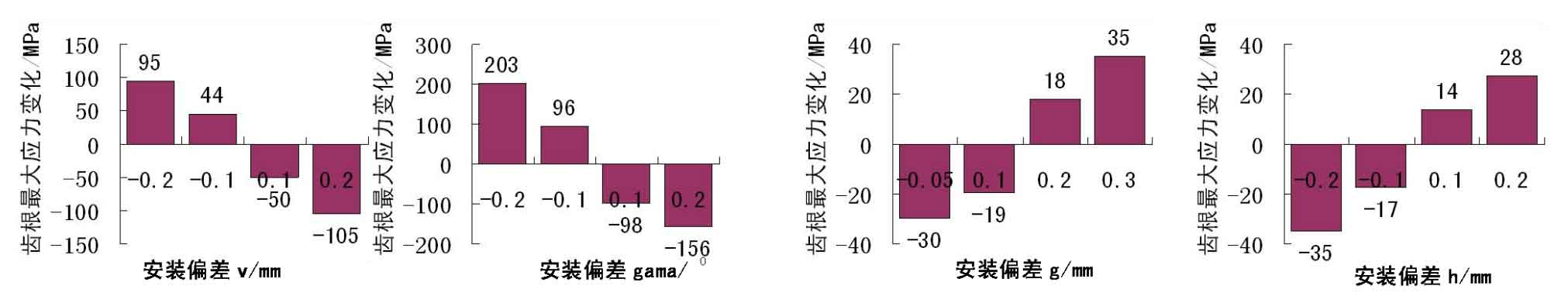

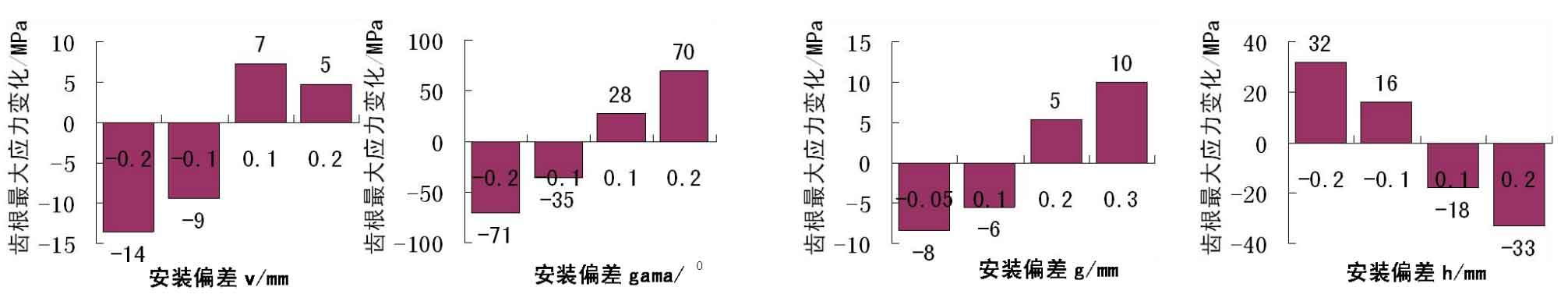

The variation of the maximum stress of the pinion root with the installation deviation is shown in Figure 1 and Figure 2. It can be seen that the maximum principal stress of the pinion root is more sensitive to the installation deviation than that of the big gear. The influence of the installation deviation on the maximum principal stress of the root of the gear from large to small is the gear cross angle, offset distance, the axial installation position of the pinion, and the axial installation position of the big gear, that is gama>v>h>g. Based on the above analysis, the following influence rules of installation deviation can be obtained:

(1) Except for the installation deviation in G direction, the change trend of tooth root stress of large and small gears is just the opposite. The influence of gear installation cross angle deviation Gama is the most significant, followed by gear offset distance installation deviation V, and finally the axial installation deviation of large and small gears has little influence on the maximum principal stress of the tooth root. Therefore, when designing and assembling gears, it is necessary to strictly control the cross angle of gears and the installation offset distance of gears.

(2) The change of the cross angle installation deviation Gama will cause the location of the maximum principal stress at the root of the large and small gears to change, and the corresponding maximum principal stress value will also change sharply. The v-direction installation deviation will cause the location of the maximum principal stress at the root and the value of the maximum principal stress to change significantly, and the g-direction and h-direction installation deviation will have little effect on the location of the maximum principal stress at the root and the value of the maximum principal stress.