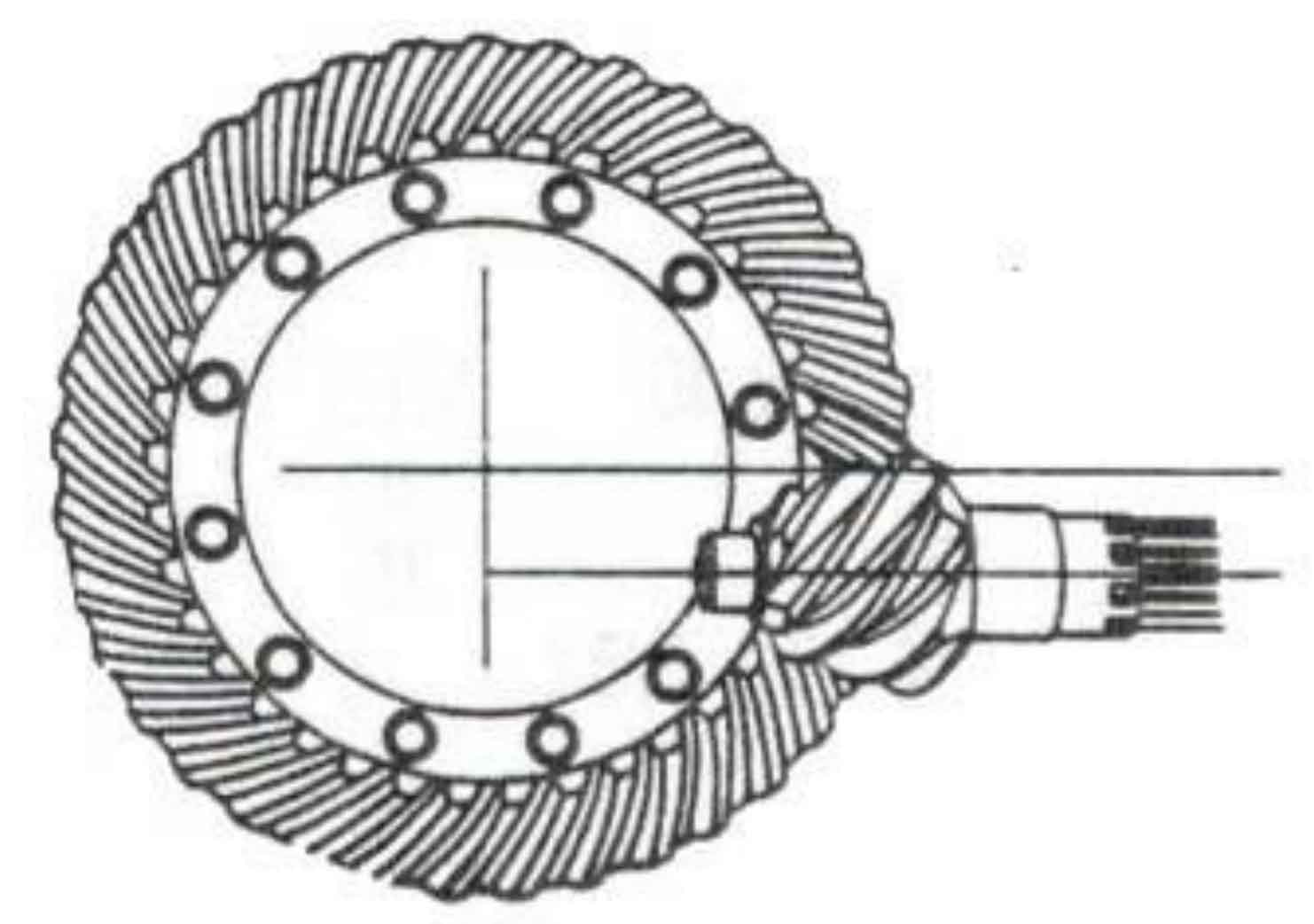

The main contents are as follows: a finite element based static transmission error calculation model is briefly described, and the key points needing attention in parameter setting of contact algorithm in the modeling process are listed. The influence of different boundary conditions and installation deviation of hypoid gears on the static transmission error of hypoid gears is analyzed, and the sensitivity of different influencing factors is analyzed. The results show that with the increase of load, the constant part of transmission error of hypoid gear increases nonlinearly, and the change period of transmission error is basically unchanged. The fluctuating part of transmission error of hypoid gear is closer to parabola shape, and the peak value of transmission error increases nonlinearly with load. The installation deviation has a great influence on the mean value of the transmission error of the hypoid gear. The negative increase of the H value, the negative increase of the g value, and the positive increase of the V value can easily lead to the positive transmission error of the hypoid gear, and reduce the meshing coincidence of the hypoid gear. Comparing the sensitivity of installation deviation to the mean value of transmission error, it can be found that the sensitivity of h-direction installation deviation and v-direction installation deviation to transmission error is basically the same, and the influence of g-direction installation deviation to transmission error is weak. The installation of the cross angle deviation Gama makes the mean value of the transmission error no longer constant, and increases the eccentric excitation of the hypoid gear, which increases the dynamic excitation of the meshing of the hypoid gear.

A kind of dynamic transmission error analysis of hypoid gear based on finite element method is established, and the differences and relations between static transmission error and dynamic transmission error are compared. The results show that there is little difference between dynamic transmission error and static transmission error. The large input speed fluctuation has great influence on the dynamic transmission error, but the change trend is the same as the static transmission error.

In view of the difficulties encountered in the calculation of time-varying meshing stiffness of hypoid gears, a complete meshing stiffness model of hypoid gears based on finite element method is proposed. The calculation method of meshing stiffness of hypoid gears by ABAQUS finite element method is described in detail, and the effectiveness of this method is verified by spur involute gears. The meshing stiffness of hypoid gears is obtained by processing the finite element calculation results. The results show that the meshing stiffness of hypoid gears changes periodically, and the changing period is the meshing period of gears. The comparison results of meshing stiffness under different loads show that the meshing stiffness of hypoid gears increases nonlinearly with the load, the average value increases and the fluctuation decreases. The calculated stiffness can be directly applied to the dynamic analysis of hypoid gear system. This meshing stiffness of hypoid gears can be applied to the dynamic analysis of hypoid gear system without any other assumptions, so it can better predict the dynamic response of hypoid gear transmission system of automobile drive axle.