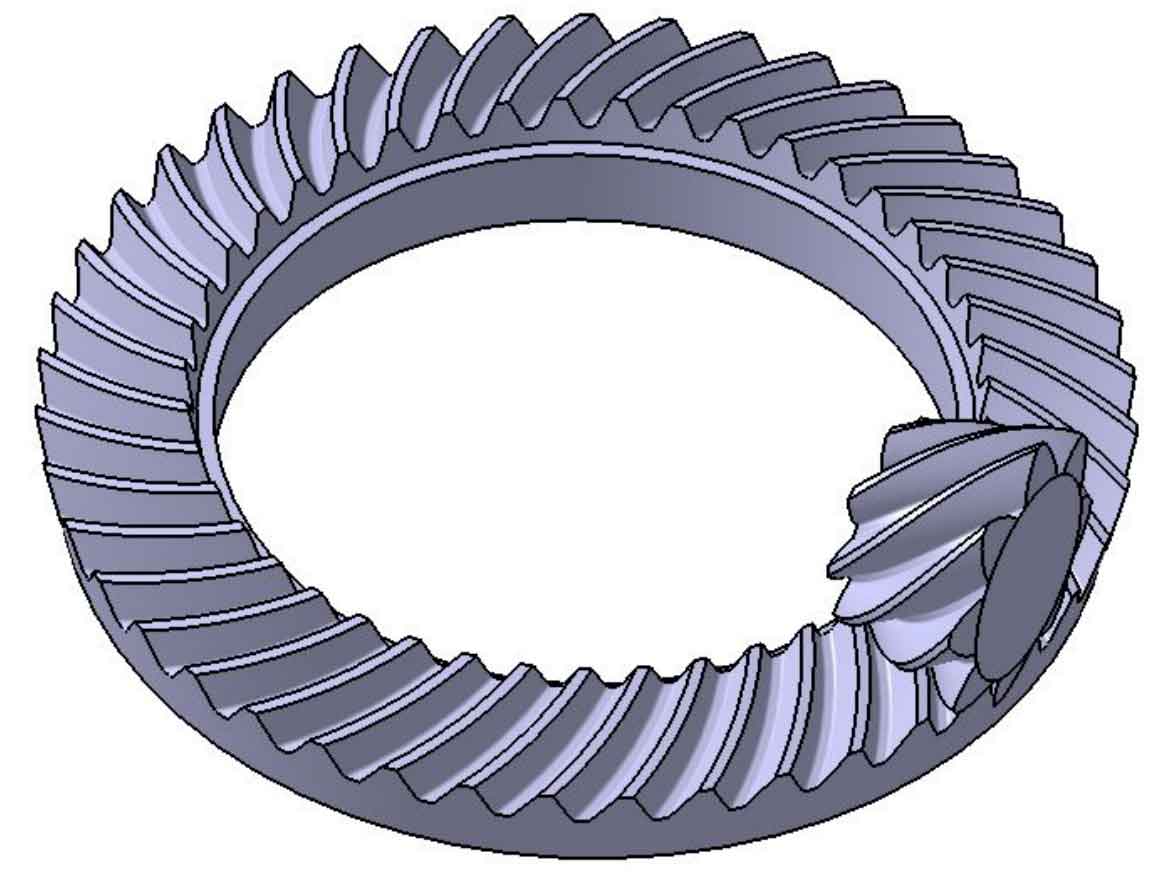

The bending fatigue strength and time-varying meshing characteristics of hypoid gears of drive axle are studied. Because of the complex geometry structure and machining method of hypoid gears, the load distribution changes with the change of meshing position.

The meshing characteristics of hypoid gears are not only related to the stress state, but also to the heat treatment process, processing technology, working temperature, lubrication conditions and other factors of the tooth surface. Due to the time and conditions, the work of this paper is not comprehensive enough, and follow-up research can be continued in the following aspects.

- Bench test of influence of bending fatigue performance of drive axle hypoid gear. Due to the limitation of time and equipment, a large number of comparative analysis tests on the factors affecting the bending fatigue of the drive axle hypoid gear have not been carried out, and these aspects can be supplemented later.

- Drive axle vibration and noise control. The noise radiation of the drive axle is the result of the interaction between the drive axle hypoid gear system and the drive axle housing. It is necessary to analyze and optimize the assembly conditions, working conditions, heat treatment process, lubrication conditions and other factors of the drive axle hypoid gear, and conduct a more comprehensive study on the gear bearing support structure, the axle housing structure, and the overall mass distribution of the drive axle.