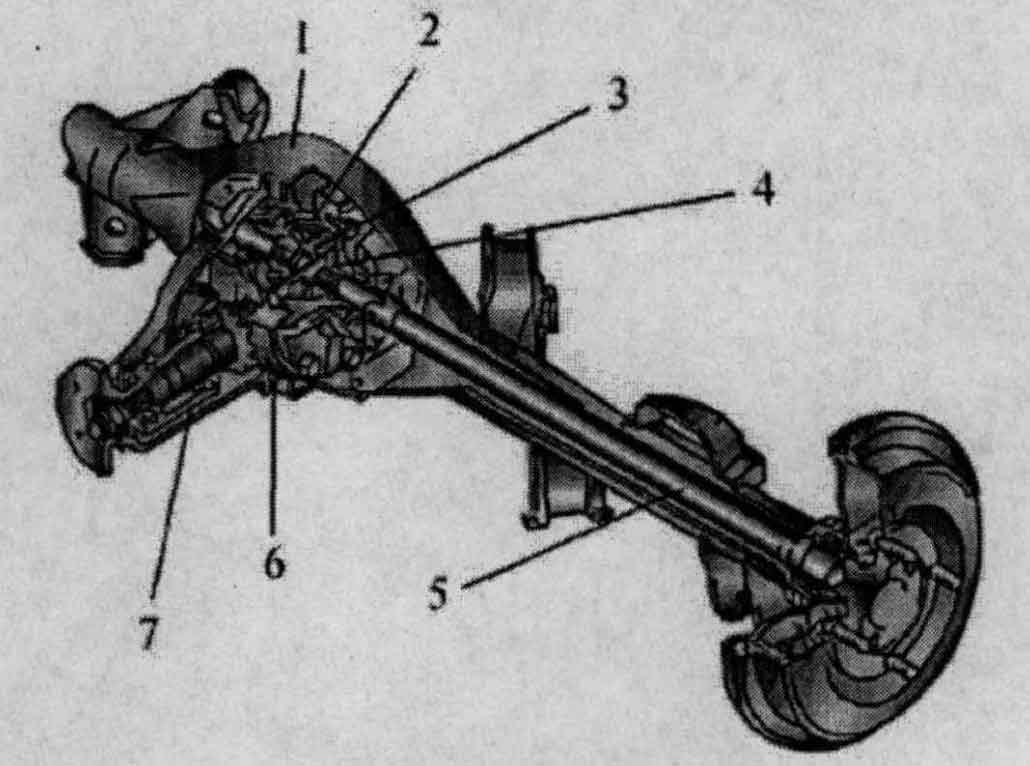

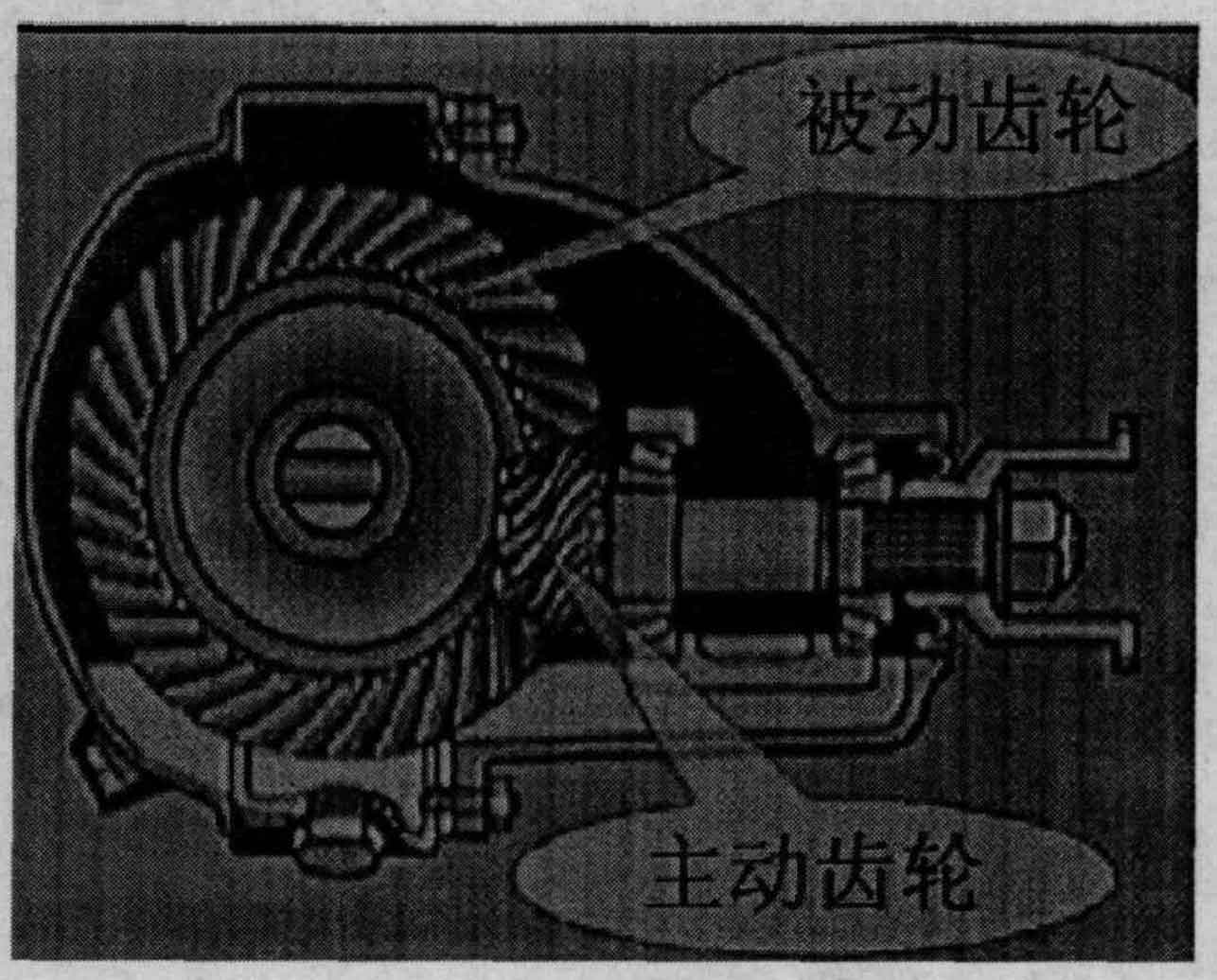

The structure of the rear axle is shown in Fig. 1. The vibration and noise are always associated with each other. People can hear the sound and feel the vibration. Through the frequency analysis, it can be seen that the “vibration problem” is mainly concentrated in the low-frequency part, and the “noise problem” is mainly distributed in the high-frequency part. The appropriate limit for distinguishing vibration and noise is 1000Hz. In other words, a frequency below 1000Hz is a vibration problem, while a frequency above 1000Hz is a noise range. In the process of transmitting power, each component of the rear axle has both low-frequency vibration and high-frequency noise. In order to ensure that the main reducer has good working performance, the hypoid gear (as shown in Fig. 2) generally has the following design requirements: high transmission efficiency, stable meshing, low noise, small volume, light weight, strong bearing capacity, reliable operation and long service life. therefore It is very necessary to model and calculate the strength accurately.

As early as the beginning of the 20th century, people began to study the vibration and noise performance of hypoid gear transmission, and achieved certain results. With the development of automobile testing technology and the wide application of various sensors, it was not until the mid-1960s that people used the vibration and noise of the rear axle to evaluate the quality of an automobile transmission system. Subsequently, it attracted wide attention around the world, and was popularized and spread all over the world.

The noise, vibration and comfort of automobile, i.e. NVH, is a comprehensive index to measure the quality of automobile production. According to statistics, about 1 / 3 of the fault problems of automobiles are related to NVH. Major automobile companies in the world have also invested 20% of the research and development expenses to solve the NVH problems of automobiles. In the automobile noise, the rear axle hypoid gear transmission noise is one of the main noise sources. Therefore, the transmission stability, vibration and noise of the rear axle assembly have an important impact on the quality of the whole vehicle. Before the assembly of the whole vehicle, it is of great significance to detect the performance of the main reducer to ensure the quality of the main reducer assembly and improve the performance index of the whole vehicle. The transmission noise of the rear axle hypoid gear, on the one hand, pollutes the environment and affects human life and health; On the other hand, it contains the fault information of hypoid gears. According to the fault information carried in the noise of hypoid gears, the system can be monitored and the fault can be diagnosed and predicted early by using the vibration and noise diagnosis method and virtual instrument technology.

The project is the test and Research on the noise performance of the rear axle assembly. The purpose is to establish the accurate model of hypoid gear and use the finite element analysis method The geometric and boundary nonlinear problems of hypoid gears in the meshing process are studied. The contact stress and tooth root bending stress of hypoid gears in the meshing process are obtained, and the variation law of contact area and contact stress of hypoid gears under large assembly error is analyzed. The modal characteristics of hypoid gears are analyzed, which provides reference for structural design and improvement, avoids the problem of large error in manual calculation, and greatly enhances the reliability of design.