There is still a certain gap between the accuracy of this method and that of contact measurement. The main reasons for the error are as follows:

(1) measurement system assembly error;

(2) error of image tilt correction;

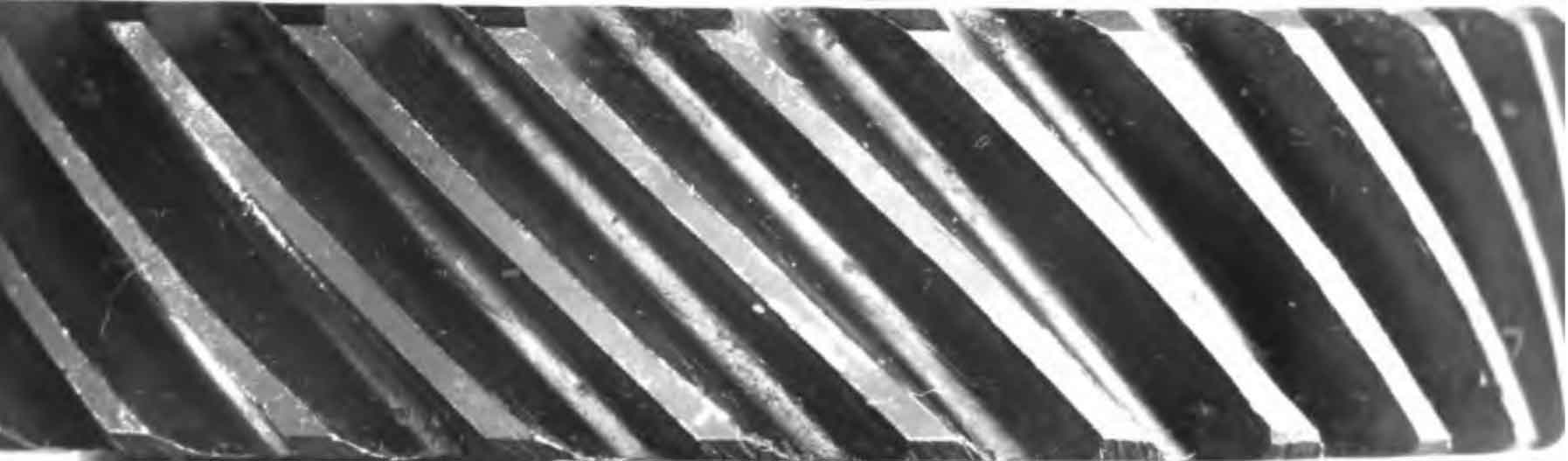

(3) tooth surface defects and stains. The defects and stains on the tooth surface cause the edges of some tooth lines to be broken, which makes it impossible to participate in the later fitting process. There are abnormal points on the extracted part of the tooth line edges. After removing them manually, the measurement error of a single edge is reduced by about 0.02 ° on average;

(4) bevel of helical gear. The bevel edge of helical gear is not on the cylindrical surface of the addendum circle. The detection accuracy of helical gears without chamfer is slightly higher than that of helical gears with chamfer. Taking a 45 ° helical gear as an example, the measurement error of a single edge is reduced by about 0.1 ° on average after removing the chamfer in some edges. On helical gears without chamfer, the θ The 0 parameter can be measured in advance by the corner detection algorithm, which can reduce the complexity of the fitting algorithm. This algorithm is more suitable for measuring helical gears without chamfer.