In order to verify the actual effect of domestic R&D and manufacturing of heavy gears, Shendong Coal Group Co., Ltd. selected the left rocker arm of 6C/LWS636 shearer and installed the corresponding domestic parts, and the right rocker arm is an imported heavy gear. Both of them went down to the well for industrial comparison test at the same time. After the assembly is completed, the loading test is carried out on a 1200 kW loading test bench. The maximum temperature of the idler gear area is 90 ℃, and the temperature of other transmission parts is lower than 95 ℃. There is no abnormal noise and oil leakage, which are in line with expectations. LWS636 shearer was put into production on March 15, 2020 at 22107 fully mechanized working face of a mine affiliated to the company. As of April 6, 2021, it has been advanced by 4500 m accumulatively and produced 6.3 million tons of coal. Seen from the use situation, the domestic rocker arm heavy gear idler gear has good performance indicators, reliable operation, meets the design requirements, and can meet the needs of high production and efficiency in coal mines.

At the same time, the processing period of a single heavy gear is about 45 days, which is 180 days longer than the shortest time of imported parts. The average cost of a single piece is reduced from 40000 yuan to about 18000 yuan, with a cost reduction of nearly 55%. If the company uses a total of 31 06 and 6C shearers, and each one is replaced with 10 heavy gears, the cost of accessories can be saved by nearly 7 million yuan in each overhaul cycle, with objective economic benefits.

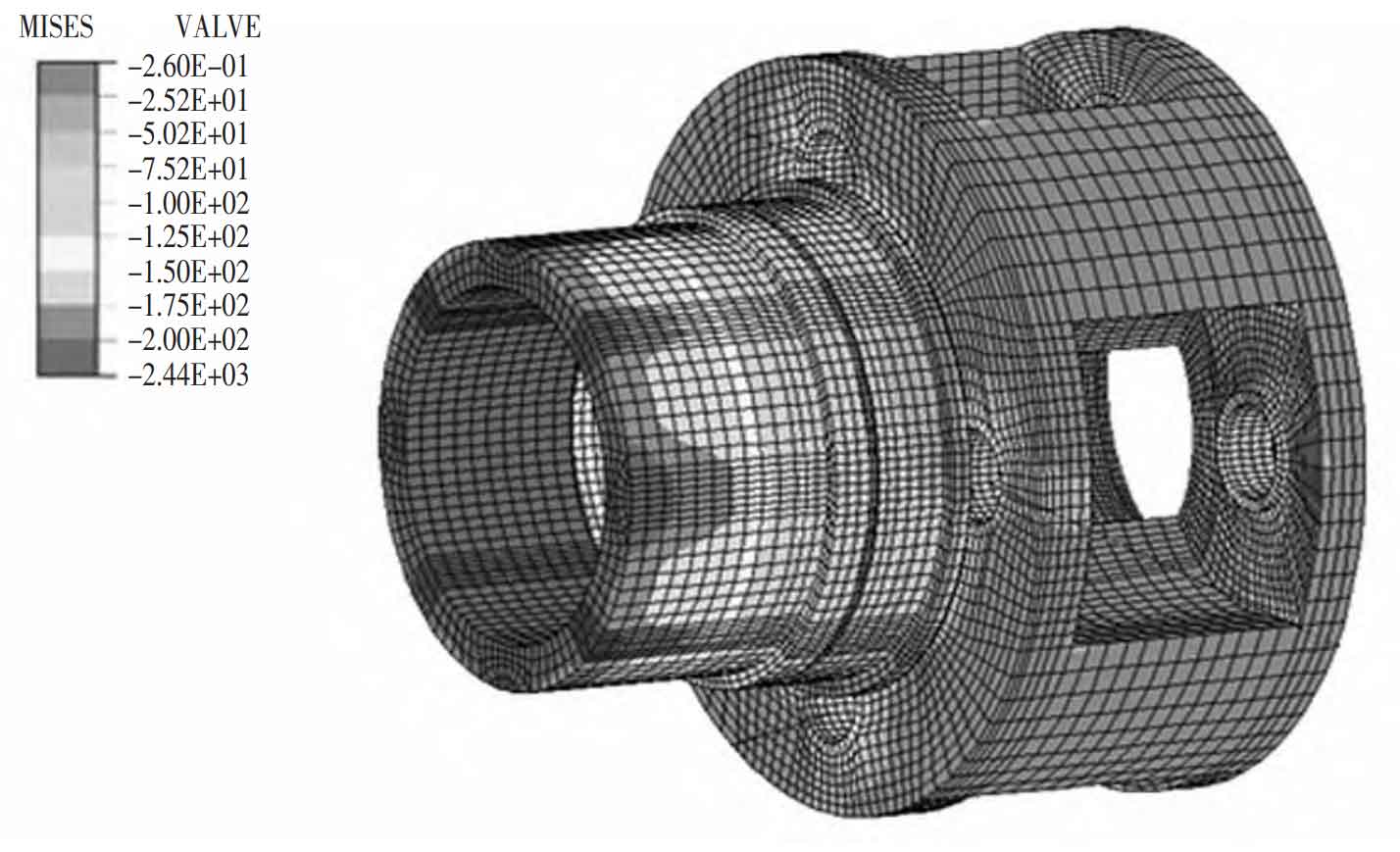

By taking the rocker arm heavy gear transmission idler of imported shearer as the research object, combining with the actual working conditions, deeply studying its stress condition, base metal characteristics, design parameters, etc., combining with the existing production technical conditions, we have carried out localization development research on it, and manufactured a product that can be completely interchangeable with it, has highly matched performance indicators, has the shortest cost and delivery time, and has guaranteed supply. It has been successfully verified by the underground industrial test. At the same time, the domestic spare parts supply channel is stable and smooth, getting rid of the impact of the international environment on imported products. The construction period and cost are controllable for enterprises, which has brought better economic benefits to coal mining enterprises. Based on this, we can further summarize experience, improve the localization manufacturing level of coal mining machinery parts, and promote the technical upgrading and industrial upgrading of the relevant national equipment manufacturing industry.