Herringbone gear is composed of two helical gears with equal helix angle and opposite direction. If the tooth surfaces on the same side of the gear teeth on both sides are required to be symmetrical about the central plane, then the spiral features on the gear teeth at the same position on the left and right sides of the gear are also symmetrical about the central plane.

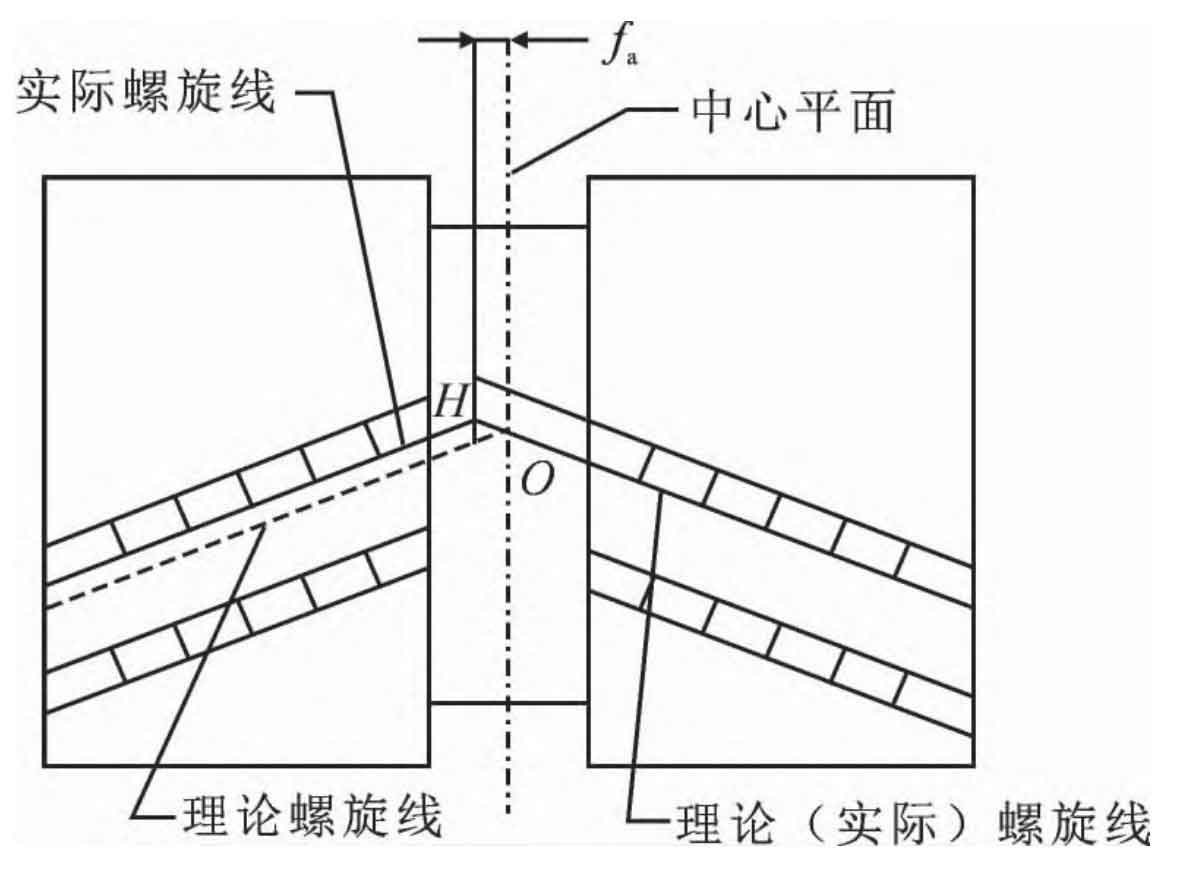

Figure 1 gives the definition of symmetry deviation when herringbone gear is unfolded along the gear indexing cylinder. That is, the intersection point O of the theoretical helix on the same side of the tooth surface of the helical gears on the left and right sides of the herringbone gear should be located on the central plane. However, due to gear processing and manufacturing errors, the intersection point of the helices on both sides of the actual tooth surfaces on the development plane of the indexing cylinder deviates from the H point of the central plane, so the distance between the actual intersection point H and the central plane is defined as the symmetry deviation fA of the herringbone gear.

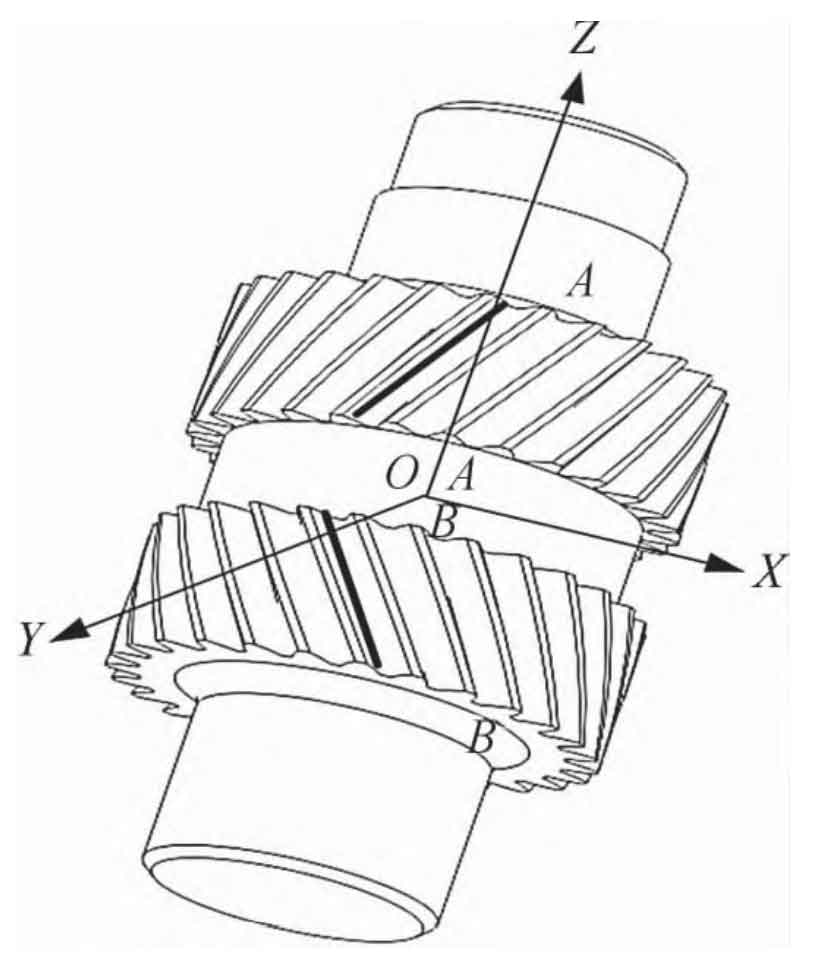

According to the definition of symmetry deviation, and considering the method of gear pitch measurement, the measurement model of symmetry deviation of both sides of helical corporate gear is built, and the measurement coordinate system of symmetry deviation is shown in Figure 2.

The symmetry deviation of herringbone gear is measured at the CNC gear measuring center shown in Figure 3. The measured gear parameters are shown in the table.

| Parameters | pinion | wheel |

| Number of teeth z/piece | 27 | 81 |

| Tooth width B / mm | 30 | 30 |

| Normal modulus mn / mm | 3.5 | 3.5 |

| Normal pressure angle α n/(°) | 20 | 20 |

| Standard center distance a / mm | 218.2 | 218.2 |

| Helix angle β/ (°) | 30 | 30 |

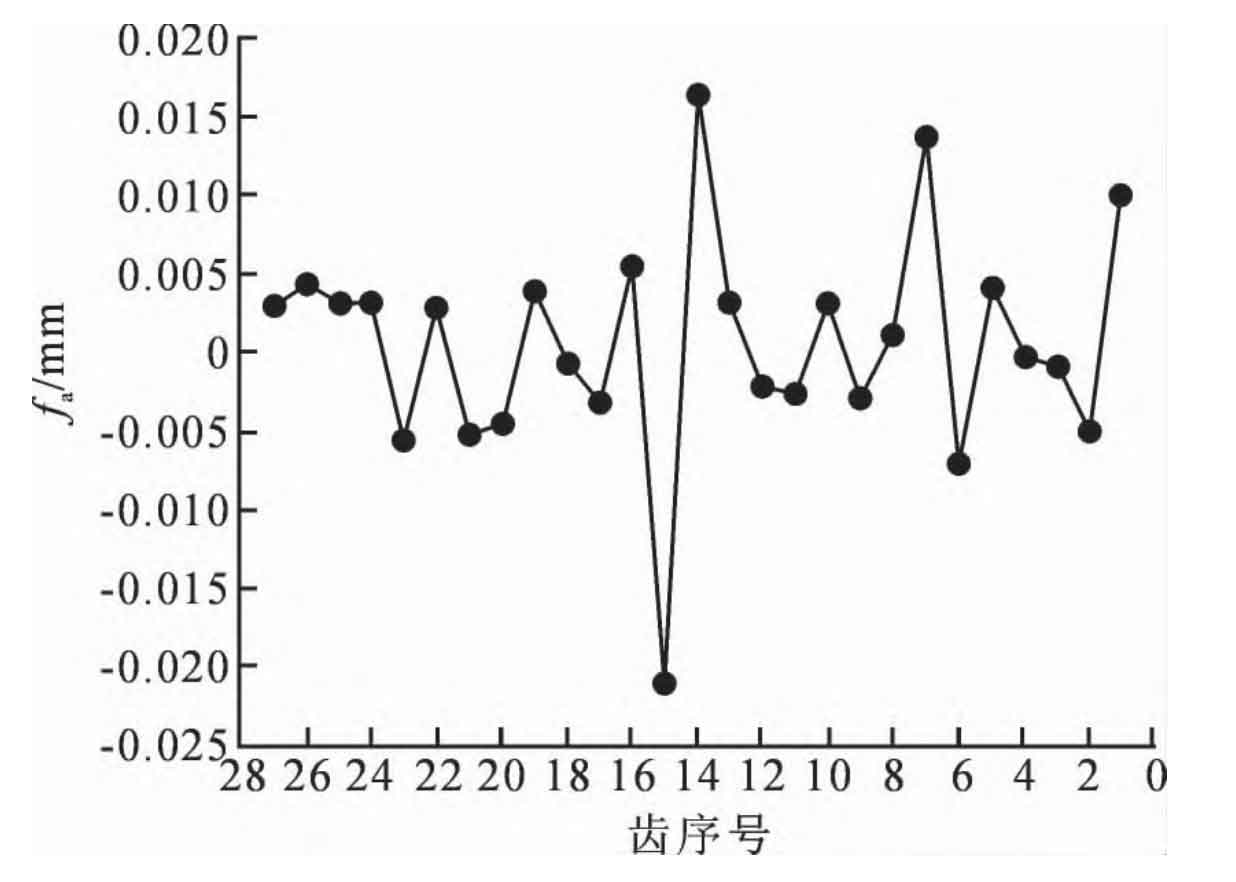

The measurement result of the symmetry deviation of the gear pinion is shown in Figure 4, where the abscissa is the serial number of the teeth and the ordinate is the symmetry deviation of adjacent teeth. It can be seen that the symmetry deviation between No. 15 gear and No. 16 gear is obvious.

The sampling data is processed and the symmetry deviation of the gear pinion is obtained as fa1=0.025mm by statistical analysis. Using the same measuring principle and method, the measured symmetry deviation of the big wheel is fa2=0.048mm