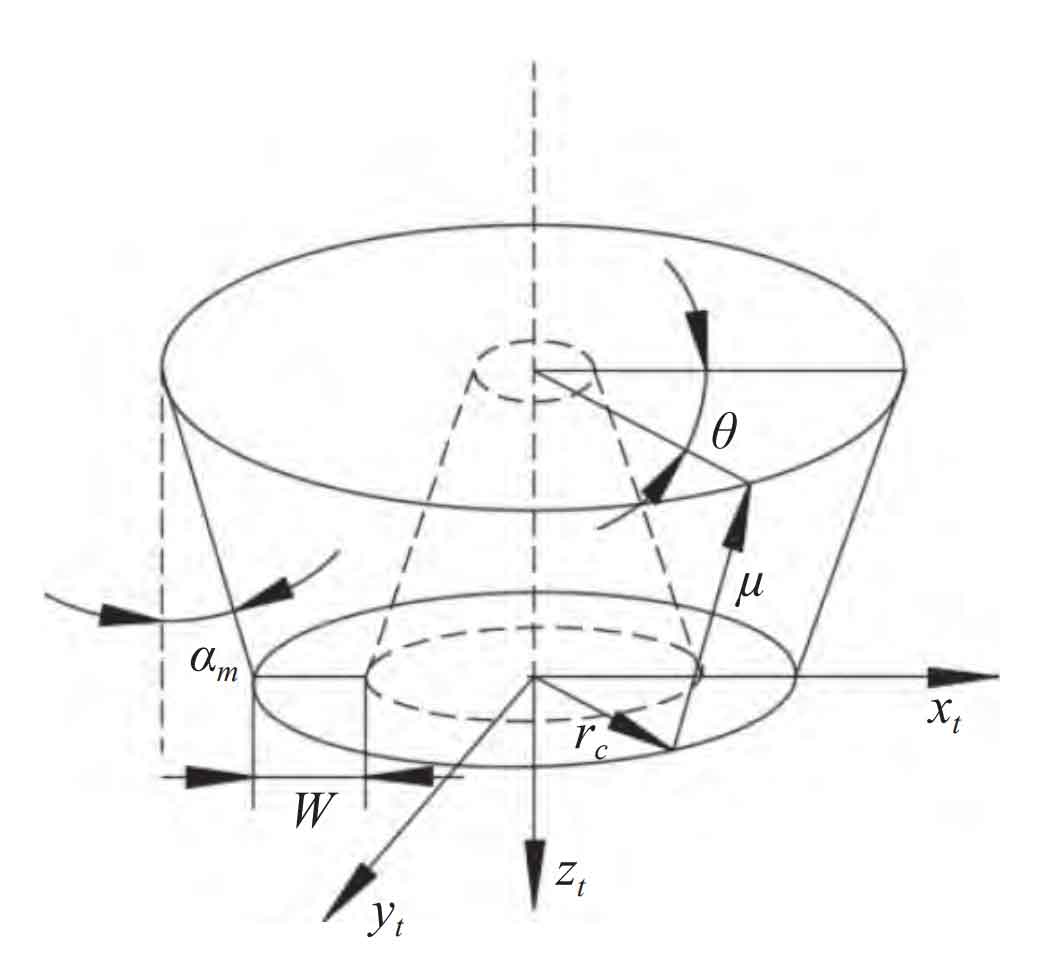

When the spiral bevel gear is machined with the forming method, the internal and external cutting edges rotate around the center of the cutter head to form two conical surfaces, and the cutter head coordinate system is established as shown in the figure.

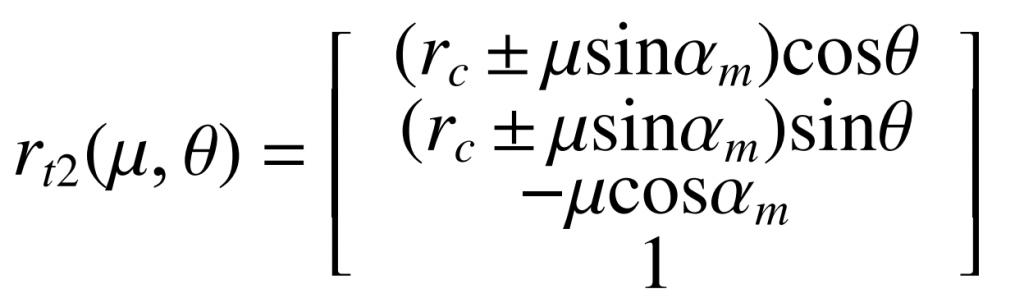

According to the cutter head coordinate system of the spiral bevel gear big wheel processed by the forming method, the equation of the generating surface of the internal and external blades can be obtained as follows:

Where: is the moving point parameter on the blade forming surface; Is the radius at the tip of the internal and external blades, where is the nominal radius of the cutter head, representing the tool offset, “” for the external cutter and “−” for the internal cutter. Is the tooth shape angle of the internal and external blades, where “+” means the external blade and “−” means the internal blade.