Knocking mainly occurs on the helical gear box components such as meshing no-load helical gear, synchronizer and sliding sleeve. Due to the discontinuous ignition of the internal combustion engine of the fuel vehicle, the combustion explosion of the gas in the cylinder, and the reciprocating motion of the piston and other phenomena, it is easy to cause severe torque fluctuations in the transmission system, affect the engine output speed and torque, and in addition, there is a backlash, which ultimately makes the no-load helical gear appear knocking vibration noise. In addition, the helical gear knock noise is also proportional to the engine speed fluctuation. Although the electric vehicle is separated from the internal combustion engine, the fluctuation of motor output speed and torque still exists, so the helical gear knock noise cannot be avoided, but it is relatively light compared with the traditional fuel vehicles. Next, the formation process of helical gear knock noise is discussed with a typical four cylinder gearbox.

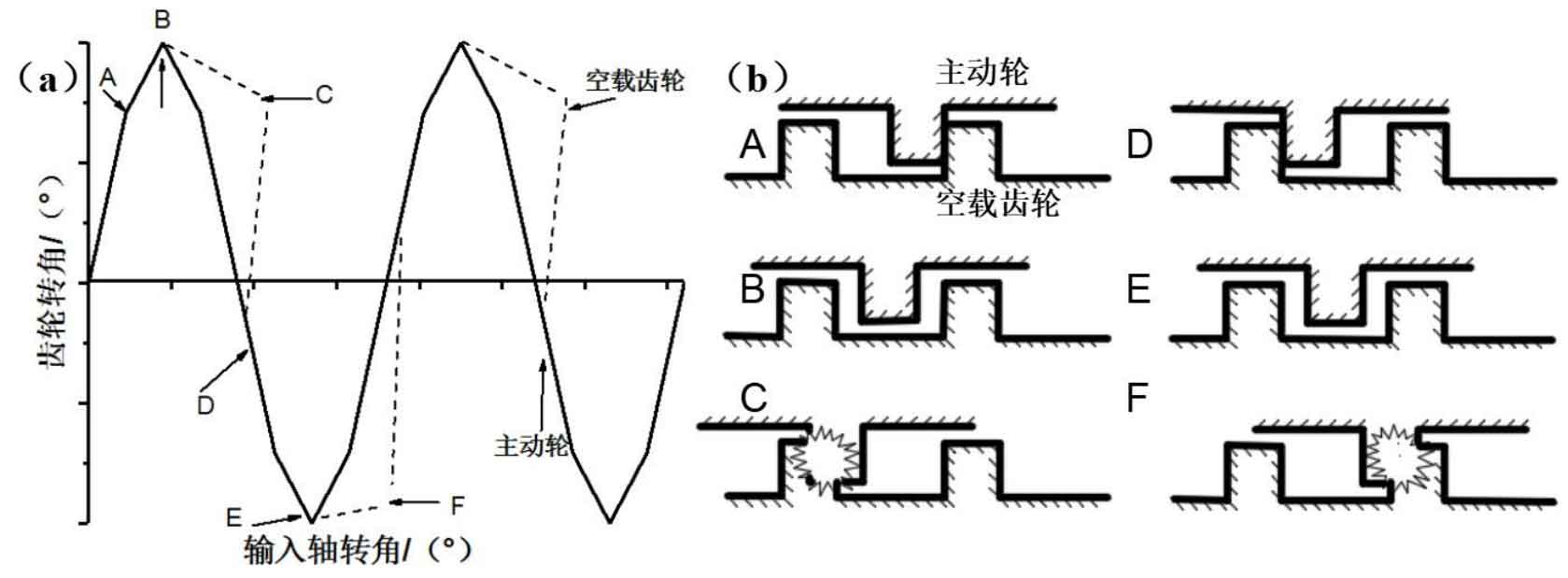

(b) Relative position of master and slave wheels when the crankshaft rotates for one circle

As shown in Figures (a) and (b), they are the angular velocity relationship curve and relative position of the driving and driven wheels when the crankshaft rotates for one cycle. For the convenience of analysis, it is assumed that the collision between gear teeth is inelastic, and the crankshaft is ignited twice every 1 revolution. At position A, the driven wheel (no load helical gear) just contacts the driving wheel and rotates to accelerate under the driving wheel. At position B, the driving wheel has the maximum speed and gradually starts to decelerate. The driven wheel also tries to maintain the same acceleration as the driving wheel under the action of the drag torque to maintain contact. However, at this time, the negative acceleration given by the gearbox to the driving wheel is often greater, so the driven wheel will produce relative movement to the non driving surface of the driving wheel. At position C, the driven wheel collides at the non driving surface of the driving wheel due to the excessive difference between the driven wheel and the driven wheel. At position D, the driving wheel continues to decelerate the driven wheel depending on the blocking effect of the non driving surface. At position E, the driving wheel starts to accelerate. Since the positive acceleration generated by the driven wheel due to the drag torque is smaller than that of the driving wheel, the teeth of the driving wheel will move towards the driving surface of the driven wheel. At F, the driving wheel speed is greater than the driven wheel, and the collision occurs at the driven surface of the driven wheel. If this is repeated, there will be a steady stream of helical gear knock noise – “click” sound inside the gearbox.