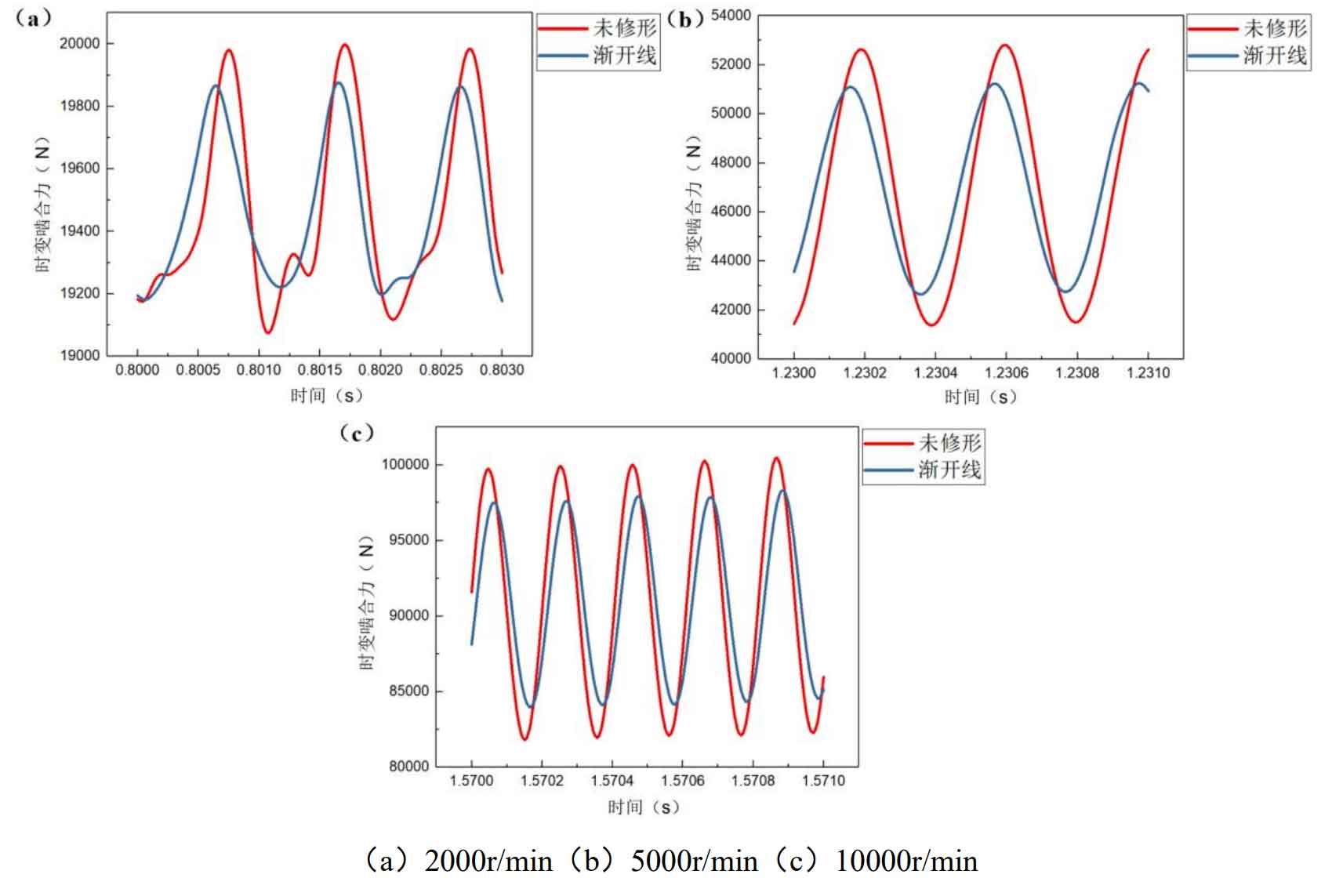

The optimal modification scheme of the addendum involute of the long tooth profile is the modification amount of the driving gear 5 μ m. Modification amount of driven wheel 4 μ m。 Figure 4.21 shows the time varying meshing force curve of the helical gear pair before and after the optimal modification of the tooth top involute of the long tooth profile at different speeds. This modification scheme effectively improves the meshing impact of helical gears. The time-varying meshing force of helical gears under all working conditions decreases significantly, and the peak values of meshing force under low speed, medium speed and high speed working conditions are only 19876.426N, 51253.637N and 98132.328N, respectively, reducing 122.687N, 1540.64N and 2348.992N.

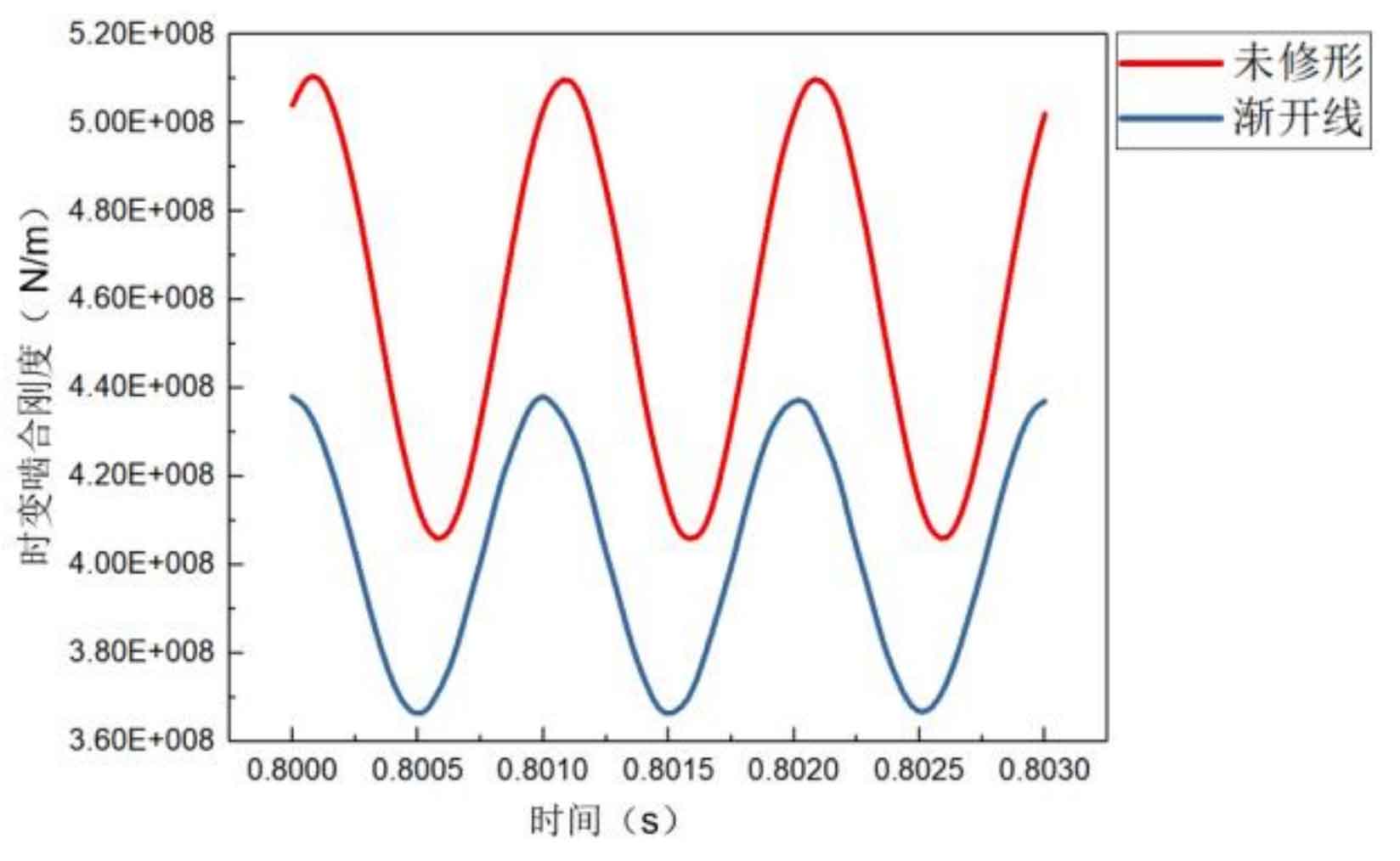

Figure 4.22 shows the time-varying meshing stiffness curves of the helical gear pair before and after the optimal modification of the addendum involute of the long tooth profile. Obviously, the scheme reduces the time-varying meshing stiffness of the helical gear pair and also reduces the fluctuation range. Its peak value is only 4.38 × 108N/m, a decrease of 14.1%; The fluctuation range is reduced to 3.67 × 108N/m~4.38 × 108N/m。

In general, the dynamic excitation of the helical gear pair of the reducer of an electric vehicle after the optimization and modification of the involute of the tooth top with a long tooth profile has decreased significantly. Although the impact of helical gear meshing under low speed conditions has not been completely eliminated, it has been significantly improved compared with the non modification, and the vibration of the helical gear pair has been greatly reduced.