1. Model simulation

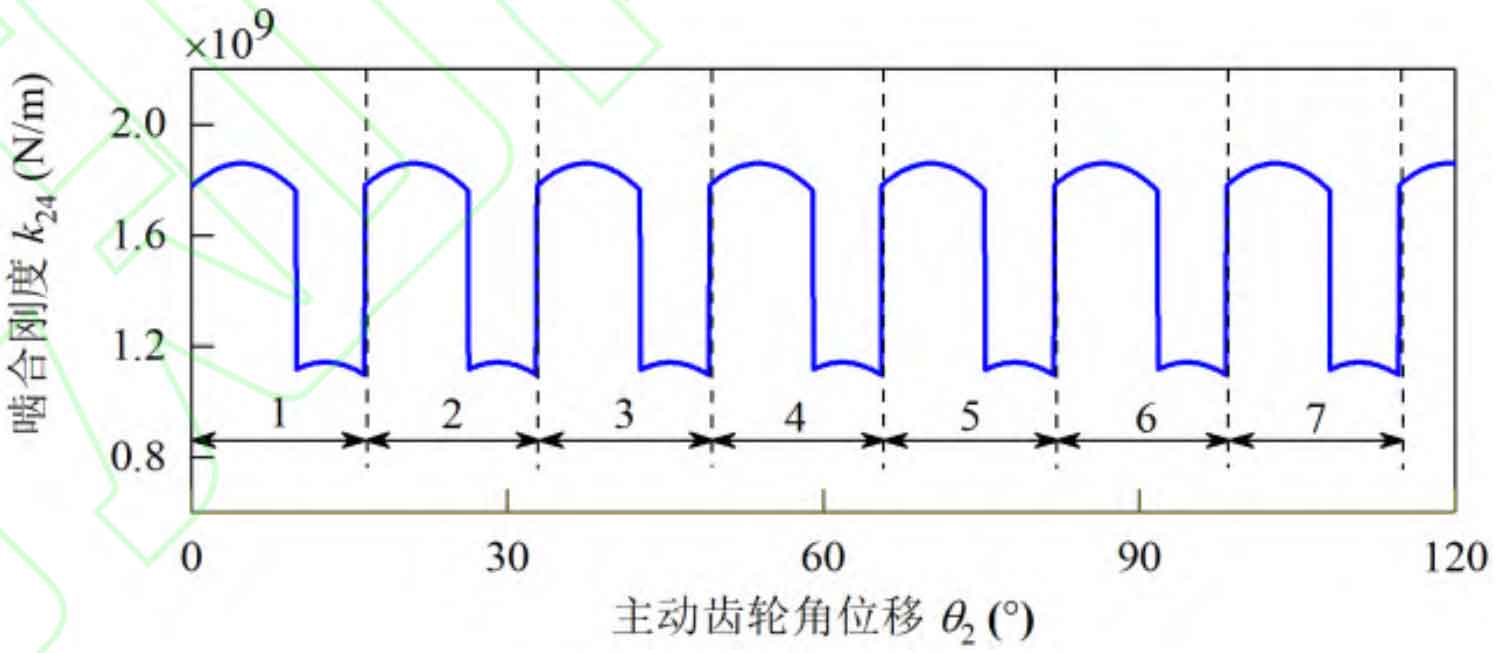

During the model dynamics simulation, the input parameters of the simulation model are determined according to the actual situation, as shown in Table 1. The calculation results of tractor gear mesh stiffness are shown in Figure 1. The meshing damping of tractor gears is proportional to the meshing stiffness, and the meshing damping ratio is selected as 0.07. The torque and speed of the power output shaft are set to 1460N ∙ m and 1000r/min respectively. Accordingly, the torque and speed of the engine are 784N ∙ m and 1864r/min respectively. The variable step size ode15s algorithm is used to solve the differential equation.

| Parameters | Gear 2 | Gear 4 | Gear 5 |

| Number of teeth | 22 | 41 | 24 |

| Tooth width/mm | 28 | 28 | 22 |

| Modulus/mm | 6 | 6 | 3.5 |

| Radius of base circle/mm | 62 | 116 | 40 |

| Pressure angle/(°) | 20 | 20 | 20 |

| Lateral support stiffness/(N · m-1) | 5.0X10^8 | 5.0X10^8 | 5.0X10^8 |

| Vertical support stiffness/(N · m-1) | 5.0X10^8 | 5.0X10^8 | 5.0X10^8 |

| Lateral support damping/(N · m-1 · s) | 4.0X10^5 | 4.0X10^5 | 4.0X10^5 |

| Vertical support damping/(N · m-1 · s) | 4.0X10^5 | 4.0X10^5 | 4.0X10^5 |

| Poisson’s ratio | 0.25 | 0.25 | 0.25 |

| Young’s modulus/GPa | 207 | 207 | 207 |

2. Bench test

The tractor PTO loading test bench is mainly composed of loading motor, torque sensor, speed sensor and position adjuster, as shown in Figure 2a. The test site is located in Luoyang Xiyuan Vehicle and Power Inspection Institute Co., Ltd. In order to verify the established dynamic model, the input parameters in the bench test and simulation model are consistent. In the process of PTO loading, the vibration acceleration signal of the power output drive train is collected. As shown in Fig. 6b, the vibration sensors are arranged at the top, left side and shaft end of the gearbox housing to collect the vibration acceleration signals of the system in the horizontal (X), vertical (Y) and axial (Z) directions respectively. The sampling frequency of the sensor is set to 6000Hz.