In order to study the influence of rotary tillage working load on the power output transmission system, the tractor gear takes the field data collected as the input parameters of the above model, and obtains the dynamic response of the power output transmission system in different working gears through the numerical solution algorithm.

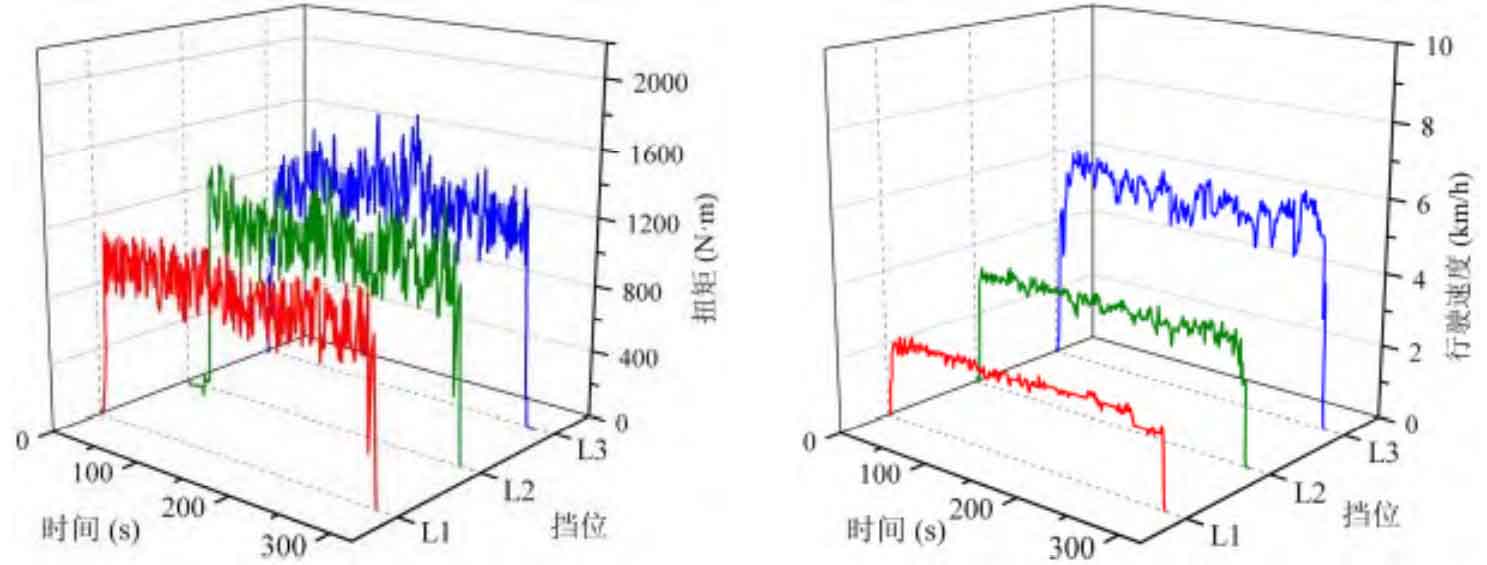

The actual driving speed and PTO load of rotary tillage operation with tractor gears in L1, L2 and L3 gears are shown in Figure 1. In order to describe the load characteristics of rotary tillage in the field, the mean value and standard deviation are selected as the statistical characteristic parameters, and the statistical results are shown in the table. According to the statistical results of the field test, the average driving speed of the tractor in the three gears is 2.07, 3.10 and 5.29 km/h. In addition, with the increase of operating gear and driving speed, the mean and standard deviation of PTO torque become larger, which indicates that the load level and fluctuation range of rotary tillage are increasing.

| Gear | Average driving speed (km/h) | Standard deviation of driving speed (km/h) | Mean value of PTO torque (N · m) | Standard deviation of PTO torque (N · m) |

| L1 | 2.07 | 0.32 | 910.79 | 204.54 |

| L2 | 3.10 | 0.59 | 987.47 | 363.10 |

| L3 | 5.29 | 0.95 | 1145.83 | 394.52 |

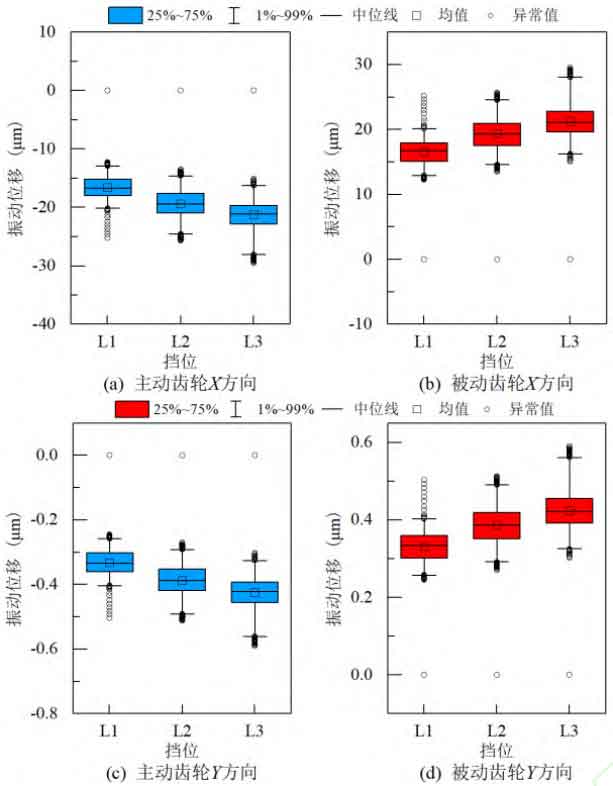

On the basis of the above analysis, the field data are substituted into the dynamic model for solution calculation. The tractor gear transmission system is the main component of the power output transmission system, and its load characteristics have an important impact on the operational reliability. Therefore, the dynamic response data of this part are statistically analyzed using the box graph.

Figure 2 shows the lateral (X) and vertical (Y) vibration displacement of the tractor driving and driven gears in the power take-off transmission system at L1, L2 and L3 gears. In the transverse direction (X), the mean values of the vibration displacement of the tractor driving gear and driven gear in the three operating gears are 16.58, 19.34 and 21.23 respectively μ m. The displacement fluctuation amplitude is 7.25, 9.94 and 11.78 respectively μ m; In the vertical direction (Y), the mean values of the vibration displacement of the driving and driven gears of the tractor in the three operating gears are 0.33, 0.38 and 0.42 respectively μ m. The displacement fluctuation amplitude is 0.14, 0.20 and 0.23 respectively μ m。 The lateral vibration of the driving and driven gears of the tractor is obviously greater than the vertical vibration, which is consistent with the simulation results of the model. It can be seen that the higher the gear of the tractor rotary tillage operation, the greater the vibration displacement of the transmission system caused by the PTO load fluctuation, which is mainly reflected in the lateral vibration.