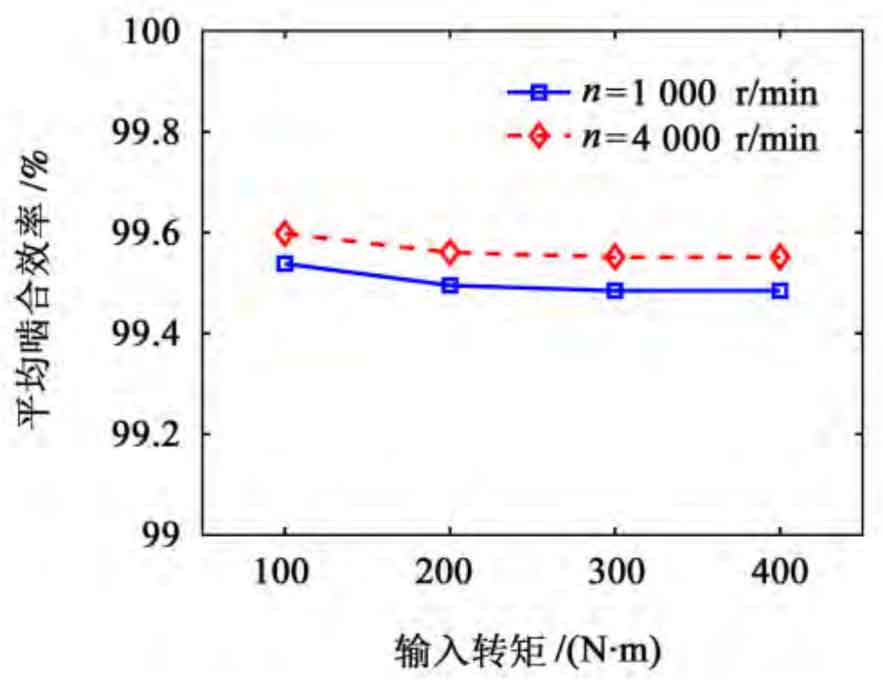

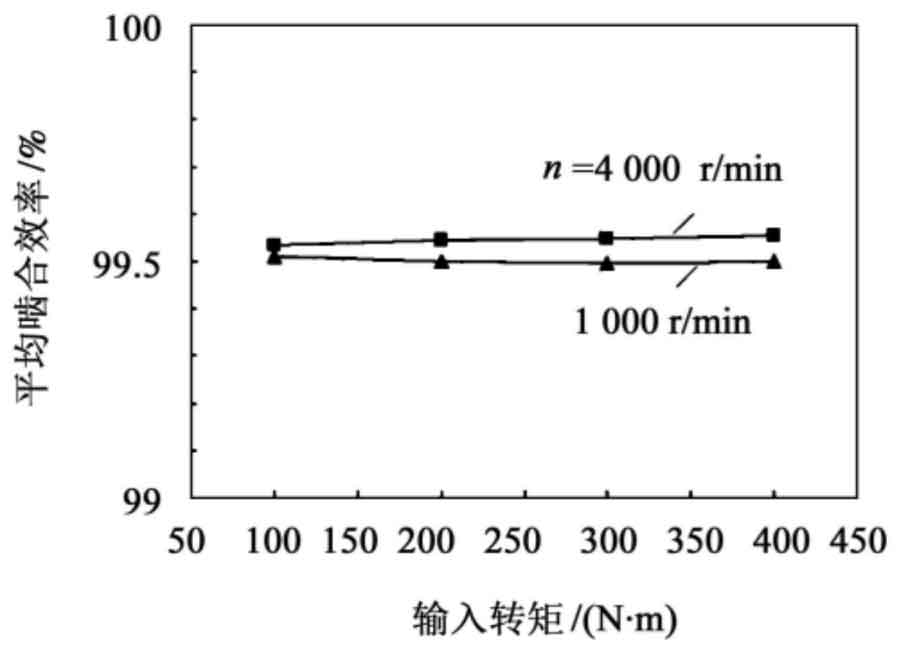

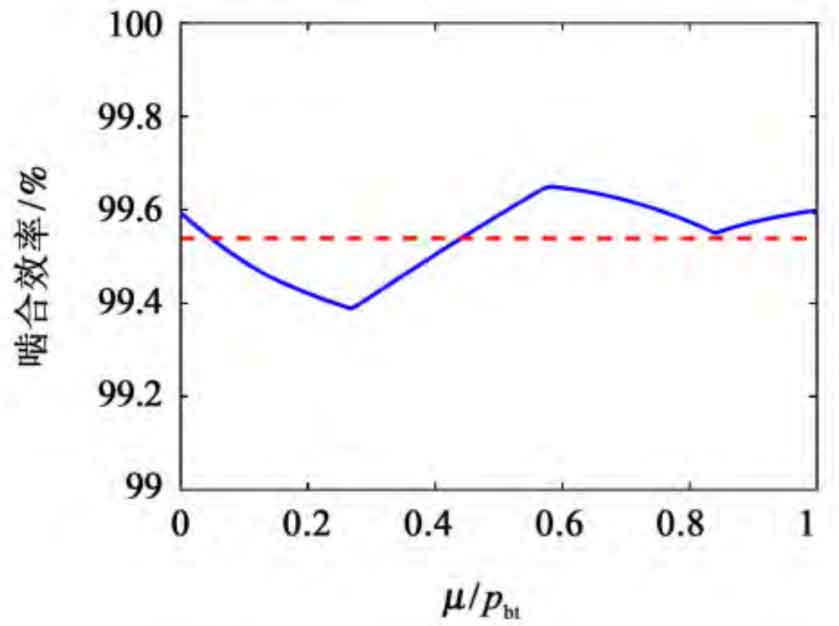

With the same parameters, the average meshing efficiency obtained is compared with the results as shown in Figure 1. It can be seen that the results are consistent as a whole, and the value is slightly larger than the result, because only the influence of sliding friction is considered, and rolling friction is not considered.

Taking a metro gear transmission system as the research object, the calculation parameters of helical gears are shown in Table. The elastic modulus E of gear material is 206 GPa, and Poisson’s ratio is 0.3; The gear tooth surface roughness is 0.8 μ m. Then the root mean square roughness S is 1.13 μ m; 75W-90 gearbox oil with density ρ= 0. 86 kg/L, kinematic viscosity at 100 ℃ ν= 15. 7 mm2/s according to ν 0 = ρν, Available dynamic viscosity of lubricating oil ν 0 is 13.5 × 103 Pa·s。

| Parameter | Driving wheel | Driven wheel |

| Number of teeth | 16 | 107 |

| Modulus mn/mm | 5.5 | 5.5 |

| pressure angle αn(/ °) | 20 | 20 |

| Helix angle β (/ °) | 17 | 17 |

| Tooth width/mm | 75 | 75 |

| Input speed (/r/min) | 1800 | 1800 |

| Input torque (/N · m) | 1008 | 1008 |

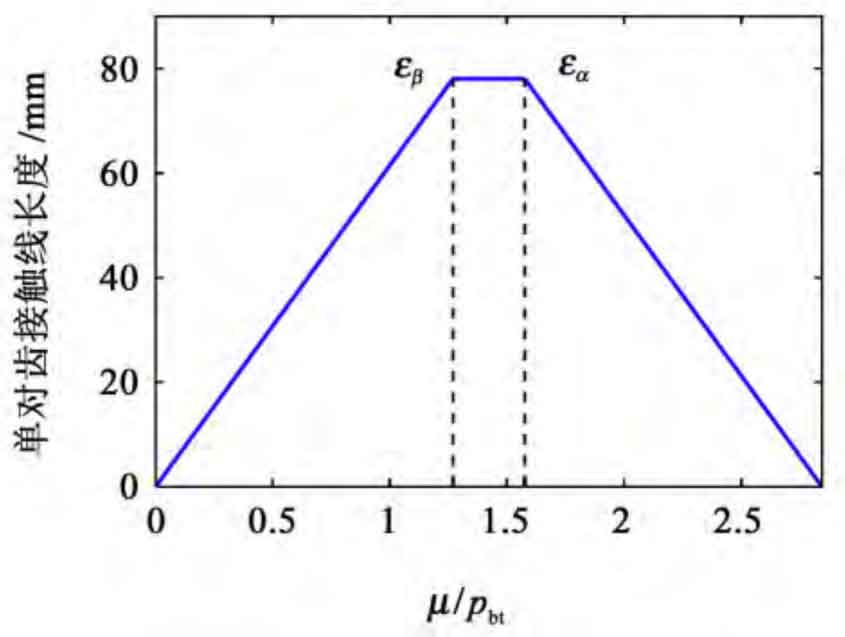

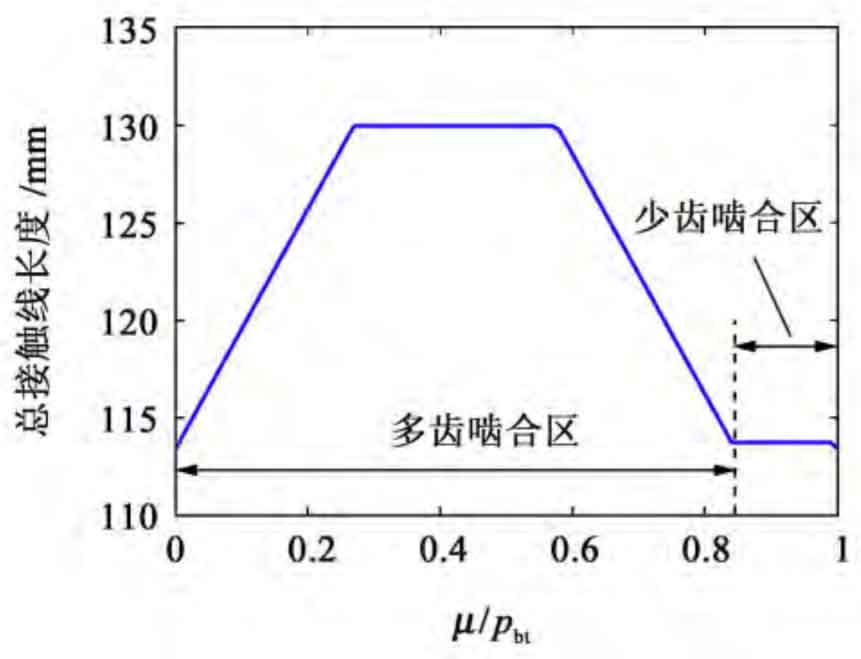

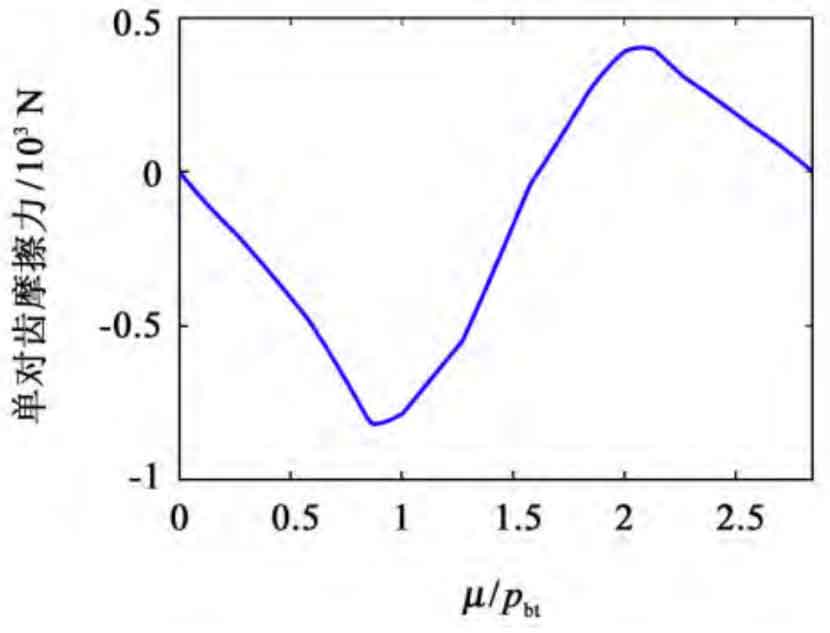

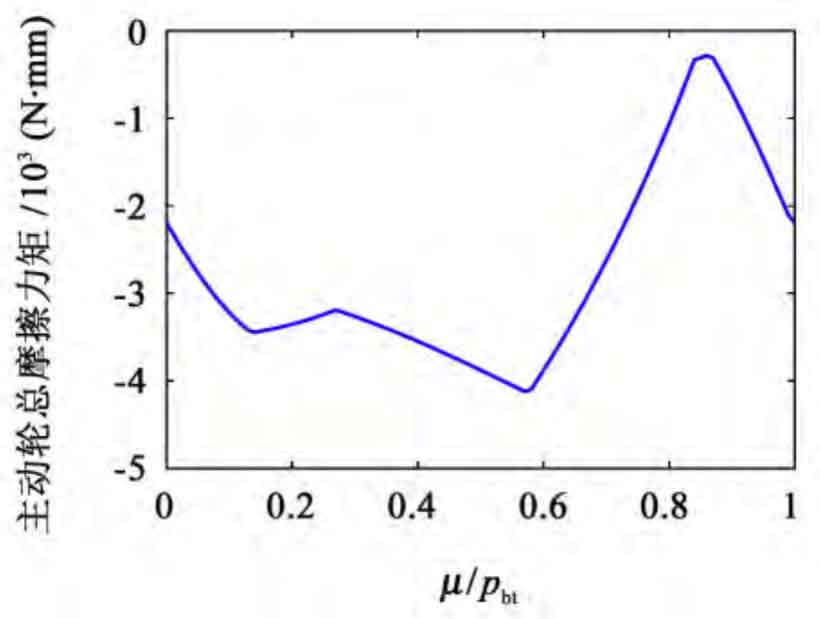

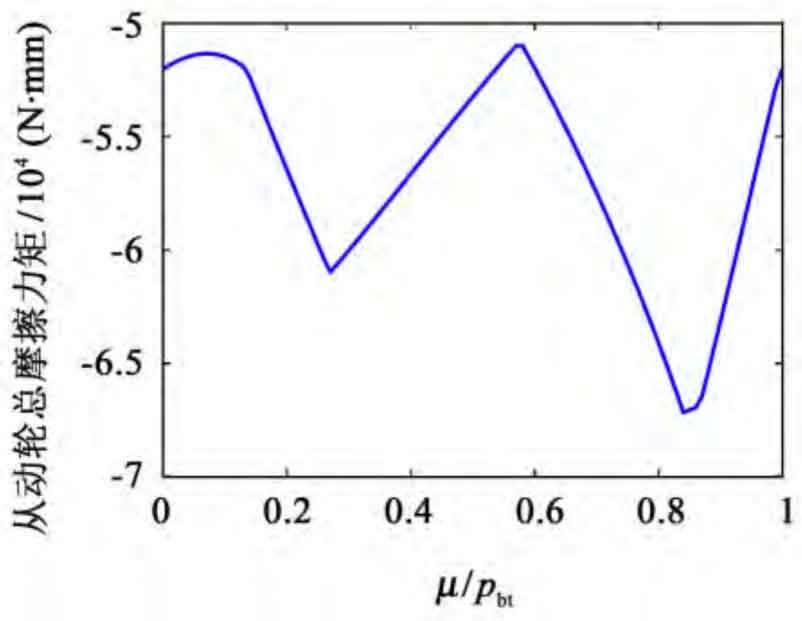

Time-varying contact line is the main factor affecting the friction excitation. Figure 2 shows the total contact wire length change. The maximum value Lmax=130 mm, and the minimum value Lmin=113.4 mm of the total contact line length obtained by calculation. Through verification, the calculation results of the contact line length extremum deduced according to the coincidence degree are completely consistent. Figure 3 and Figure 4 show the changes of friction and friction torque respectively. It can be seen that the change direction of friction force of single pair of teeth changes after the meshing point passes the node; The total tooth pair friction force increases first and then decreases as a whole, and reaches the maximum at the transition of multi tooth and few tooth engagement areas. Since the sum of the friction arm of the driving and driven wheels at any meshing position is unchanged, the change of the friction torque of the driving and driven wheels is generally opposite.

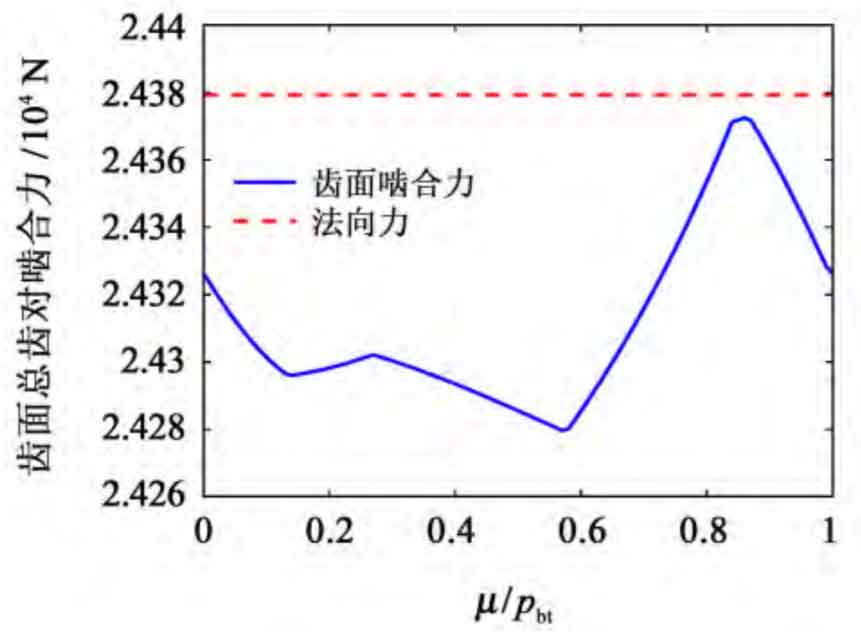

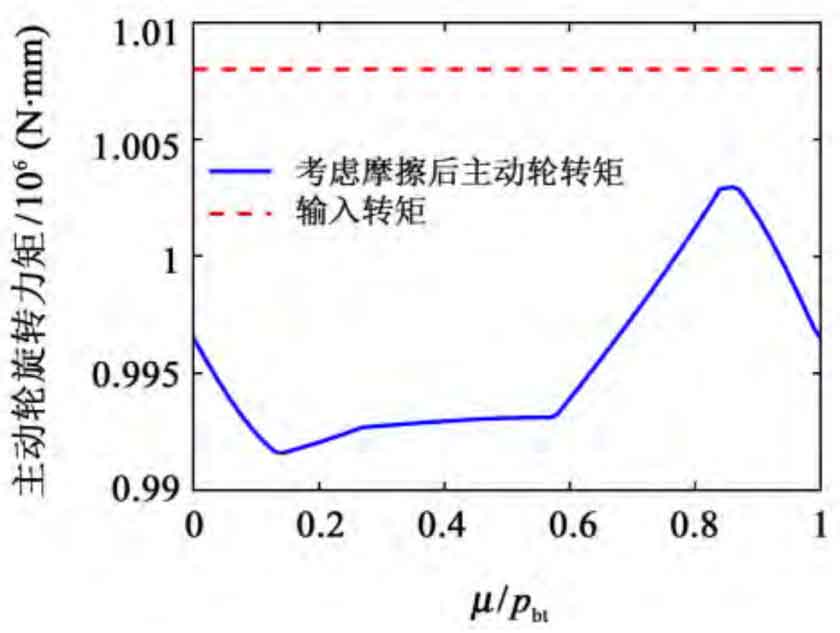

Figures 5 and 6 show the influence of friction on the meshing force of tooth surface and the torque of driving wheel. It can be seen that, due to the effect of friction and friction torque, the total meshing force of tooth pairs on the tooth surface is less than the normal force; The driving wheel torque is generally less than the input torque. Figure 7 shows the change of meshing efficiency within one base circle pitch. The maximum meshing efficiency is about 99.62%, and the friction here is also the minimum (Figure 3). As the driving wheel continues to rotate, the friction increases, the sliding friction loss increases, and the meshing efficiency decreases; Taking the average value of the instantaneous meshing efficiency in the meshing cycle, the average meshing efficiency is 99.53%.