There is less wear on the tooth root and tooth top during gear operation. On this basis, the reverse engineering software is used to measure the tooth top circle diameter Ra, tooth root circle diameter Rf, tooth number Z, and helix on the tooth profile of the end face of the gear, and then the basic parameters (full tooth height h, modulus m, and pressure angle α、 Helix angle β、 Pitch circle radius R).

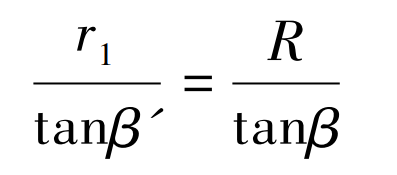

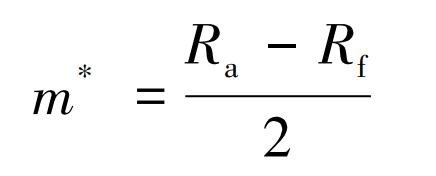

According to the design standard of double circular arc gear GB/T 12759-1991, the parameters that need to be directly measured to reverse the modulus m are the addendum circle radius Ra and the root circle radius Rf. The formula of approximate modulus m * is:

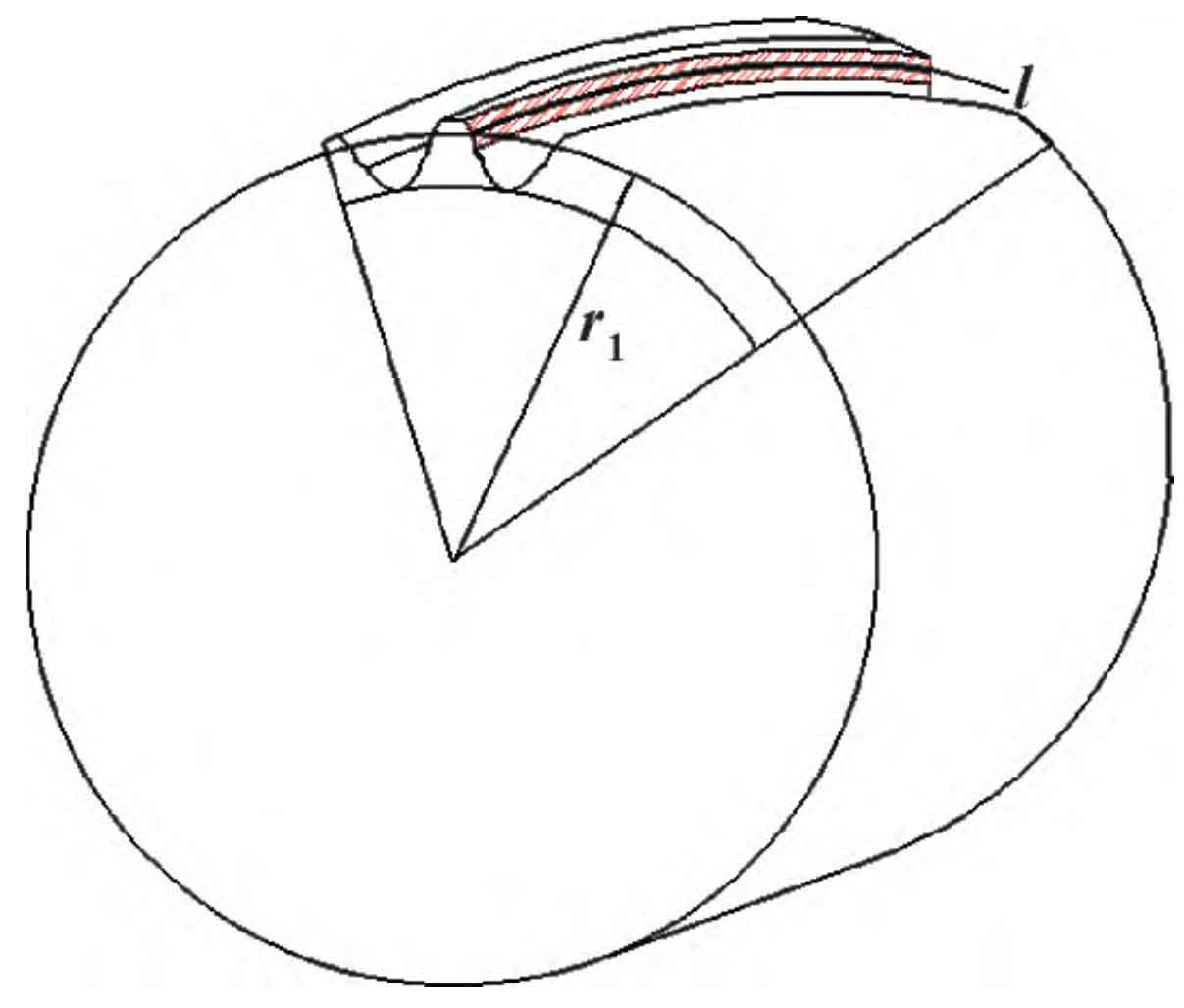

The module of double circular arc gear is the standard value. The approximate module is obtained and the standard module is rounded to obtain the gear module m. Reverse calculation of the spiral angle of the dividing circle Select the gear tooth fitting surface, establish the gear cylindrical surface, make it intersect with the fitting surface, and obtain the fitting curve, then the curve is the helix on the cylindrical surface. As shown in the figure: l is the helix under r1 cylinder, and calculate the helix angle under the cylinder β’。 The helix lead under the same gear is the same, and the helix angle under the scoring circle can be calculated β.