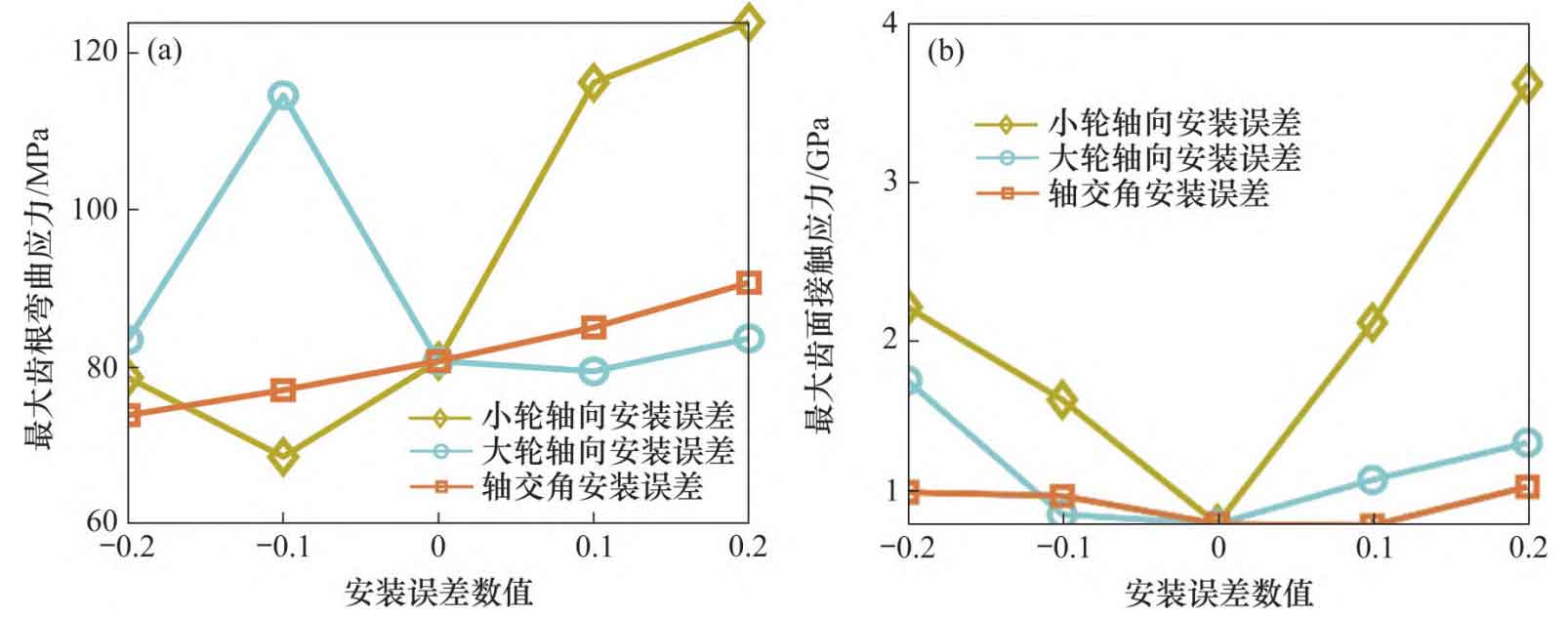

The maximum values of tooth root bending stress and tooth surface contact stress under different axial installation errors of spiral bevel gear small wheel, spiral bevel gear big wheel and shaft intersection angle are shown in the figure. It can be seen from the figure that negative axial installation error ∆ Xp of spiral bevel gear pinion has little effect on the maximum root bending stress, while positive ∆ Xp significantly increases the maximum root bending stress; When ∆ Xp is 0.2 mm, the maximum tooth root bending stress reaches 123.9 MPa; When the axial installation error ∆ Xg of spiral bevel gear big wheel is − 0.1 mm, the maximum tooth root bending stress suddenly changes to 114.6 MPa. When ∆ Xg is other working conditions, the maximum tooth root bending stress does not change significantly; Installation error with shaft intersection angle ΔΣ The maximum tooth root bending stress increases gradually from − 0.2 ° to 0.2 °; When the axial installation error ∆ Xp of spiral bevel gear pinion is 0, the maximum tooth surface contact stress is the minimum, positive and negative ∆ Xp significantly increase the maximum tooth surface contact stress, and when ∆ Xp is positive, the increase trend is greater, when ∆ Xp is 0.2 mm, the maximum tooth surface contact stress reaches 3626.8 MPa; When the axial installation error ∆ Xg of spiral bevel gear big wheel is − 0.2 mm, the maximum tooth surface contact stress is 1757.8 MPa; With the increase of ∆ Xg from 0 to 0.2 mm, the maximum tooth surface contact stress increases gradually; Installation error with shaft intersection angle ΔΣ From − 0.2 ° to 0.1 °, the maximum tooth surface contact stress decreases from 1053.1 MPa to 843.6 MPa; When ΔΣ When it is 0.2 °, the maximum tooth surface contact stress is 1088.3 MPa.

From the above analysis, it can be seen that the positive axial installation error of the small wheel has a greater impact on the meshing characteristics of the spiral bevel gear pair, the negative axial installation error of the large wheel has a greater impact on the bending stress of the tooth root and the contact stress of the tooth surface, but has a smaller impact on the transmission error, and the installation error of the shaft intersection angle, the axial installation error of the large wheel and the axial installation error of the small wheel have a greater impact on the meshing characteristics of the spiral bevel gear pair.