(1) Selection of long and short shaping methods

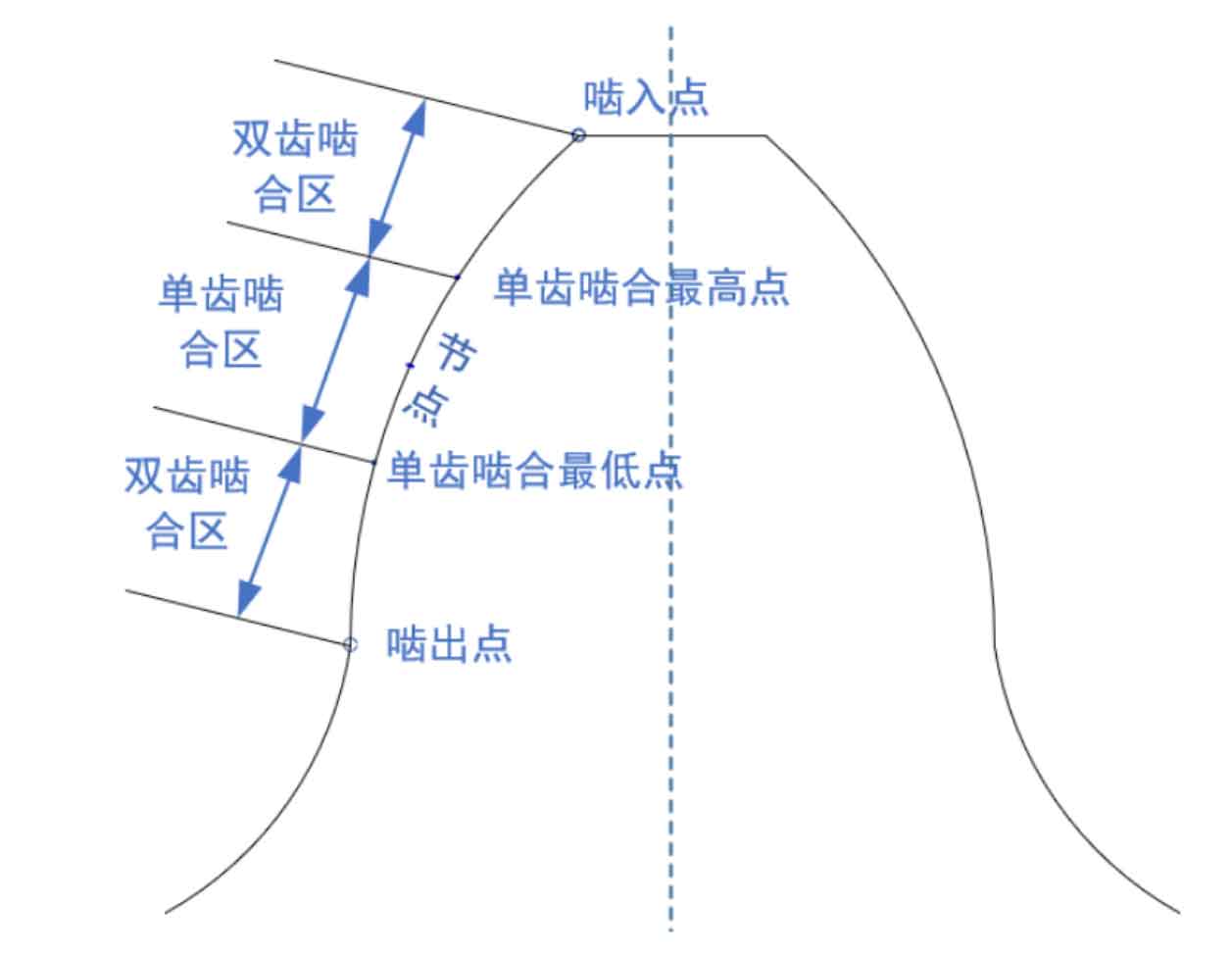

Long modification refers to the repair and removal of the part from the meshing point of single tooth to the highest point of meshing or the part from the lowest point of meshing to the meshing point of the helical gear shown in Figure 1; The initial position of the short modification is the same as that of the long one, but the length is half of the long one.

Wide helical gears with large helix angle, large fit, frequent load changes and severe working conditions shall adopt long modification, while straight gears with small helix angle and stable working conditions shall adopt short modification. Obviously, the helical gear pair studied has a large helix angle, a large degree of coincidence, and acts on high-speed and heavy-load conditions, so it is appropriate to adopt long profile modification.

(2) Selection of gear tooth modification position

Generally, the tooth root is the weakest part of the helical gear, so the strength of the tooth root determines the service life of the helical gear pair. Wu Jiang pointed out that if the tooth root of the meshing helical gear pair is modified, it will cause stress concentration and reduce the strength of the helical gear. Generally, the tooth root modification is not recommended. Therefore, in addition to the inevitable modification of tooth profile drum and tooth direction drum to the tooth root, the other modification methods only consider the tooth top modification.

(3) Selection of wheel and pinion modified helical gears

The selection of wheel and pinion modified helical gears is currently controversial in the industry. It is recommended that both wheel and pinion gears be reshaped at the same time under high speed and heavy load conditions; It is recommended to only repair the pinion under any working condition; Document [79] suggests that the high-speed gear of reducer be modified. Therefore, this paper fully considers three possibilities, namely, the simultaneous modification of wheel and pinion gears, the modification of pinion gears only, and the modification of wheel gears only, in order to avoid omitting the optimized modification scheme.

(4) Formulation of tooth profile profile modification plan

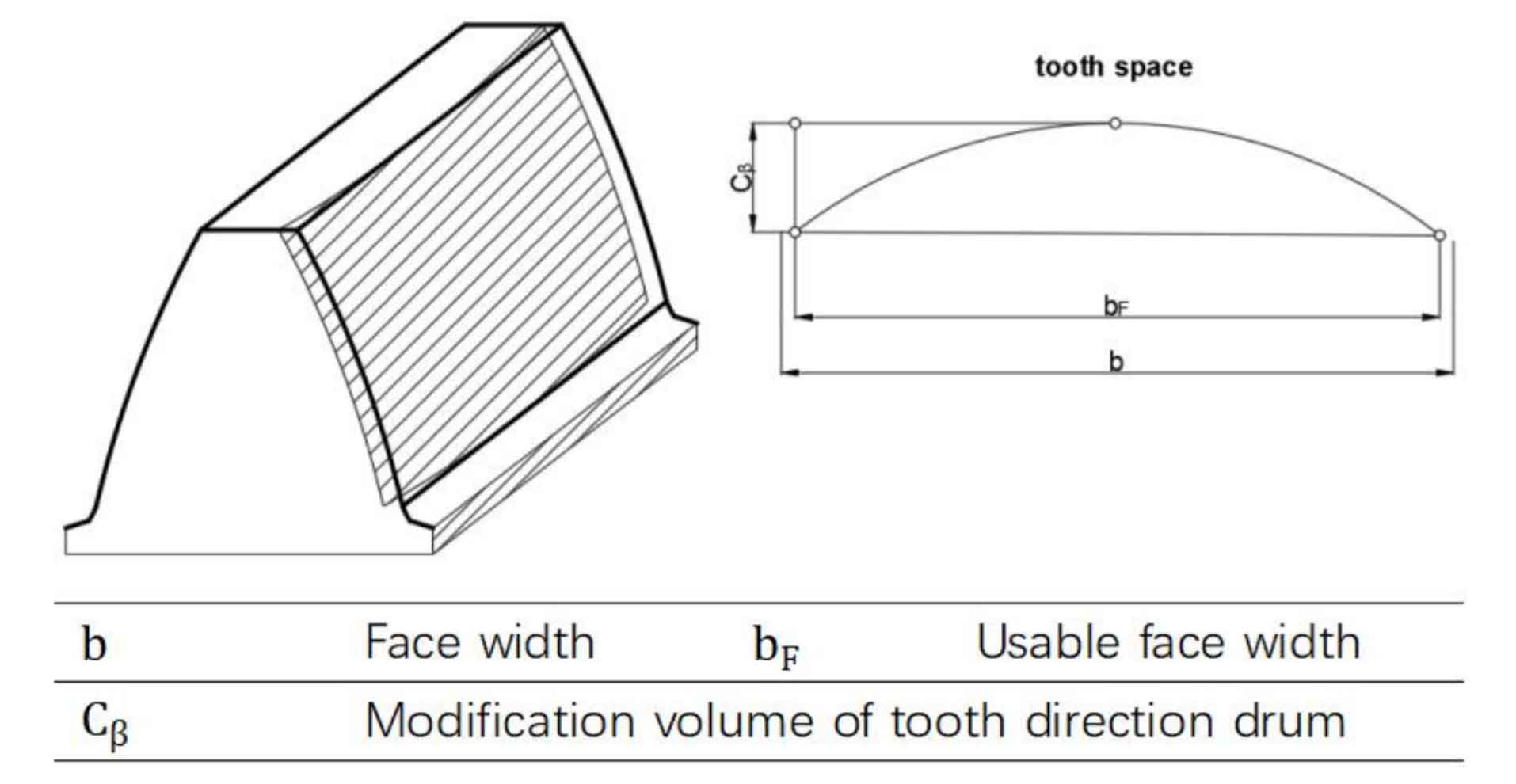

The tooth profile modification can improve the load distribution on the tooth surface, that is, reduce the Hertz contact stress of the helical gear, while the tooth profile modification is mainly to reduce the vibration noise of the helical gear, that is, the transmission error. Therefore, the idea of formulating the modification plan in this paper is to first consider the single mode of modification, that is, select the plan with the lowest Hertz contact stress and transmission error as possible as the optimal solution through the tooth profile or tooth profile modification, and then consider the tooth profile composite modification based on the tooth profile optimization modification plan. In addition, here, only the commonly used drum tooth profile modification is considered.

(5) Determination of modification quantity and precision

Generally, excessive modification will damage the structural strength of helical gear body and affect its service life and transmission performance; If the modification amount is too small, it is possible to make the modification amount close to zero under the influence of processing error and other factors, and then the modification of helical gear will become meaningless. This means that in the actual project, it is necessary to combine the analysis of specific working conditions, and consider the influence of processing equipment, human factors and various irresistible factors to select the appropriate shape modification parameters. In view of the recommended modification range of the Chinese Gear Manual is 0.7 μ m~30 μ M and the modification amount used by Eaton μ m~30 μ M, while considering that the machining accuracy of domestic imported machine tools has reached the micron level, but there is still+3 μ M processing and manufacturing error, so the range of modification is set as 3 μ m~25 μ m. The step size, namely, the trimming accuracy, is set to 1 μ m。

In order to describe some specific modification methods involved more intuitively, the shapes and general principles of different tooth profile modification methods as well as the shapes of different tooth profile modification methods have been given, and the modification principle of tooth profile drum method is shown in Figure 2.