Ideally, the smaller the backlash, the smaller the meshing impact of the helical gear pair. However, too small backlash will aggravate the tooth surface wear, which is extremely unfavorable for those gear pairs whose main goal is to improve the life of the helical gear. Therefore, it is necessary to explore the impact of the backlash on the time-varying meshing stiffness and time-varying meshing force of the helical gear.

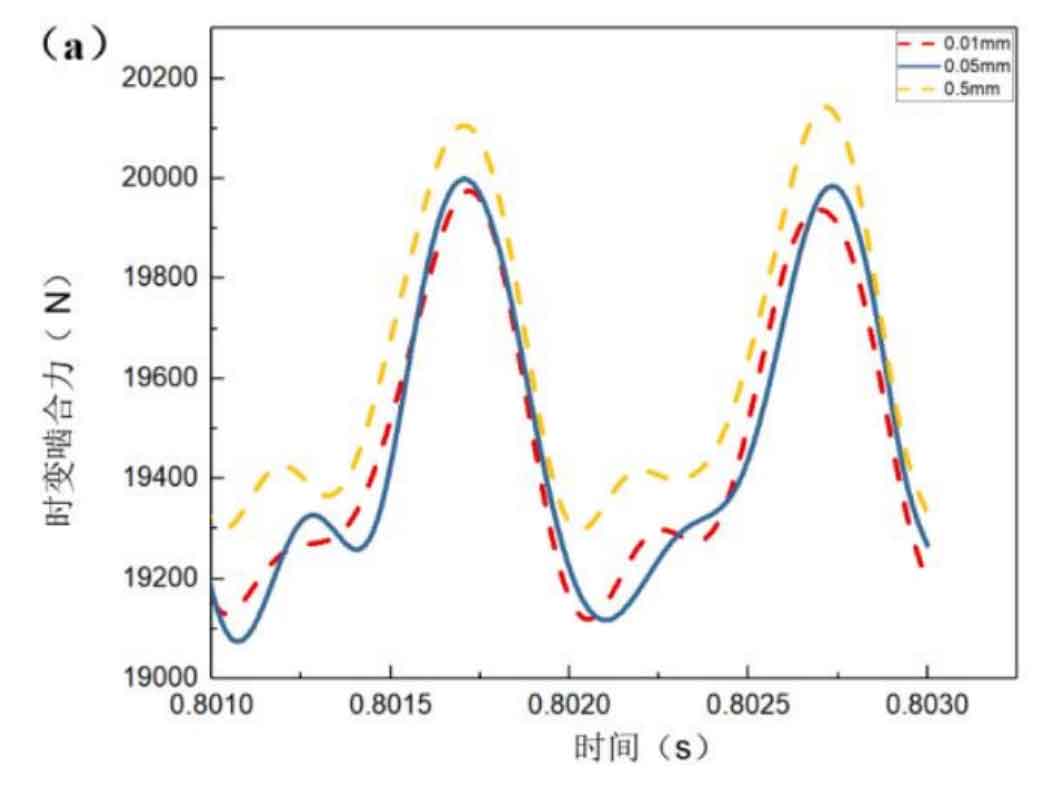

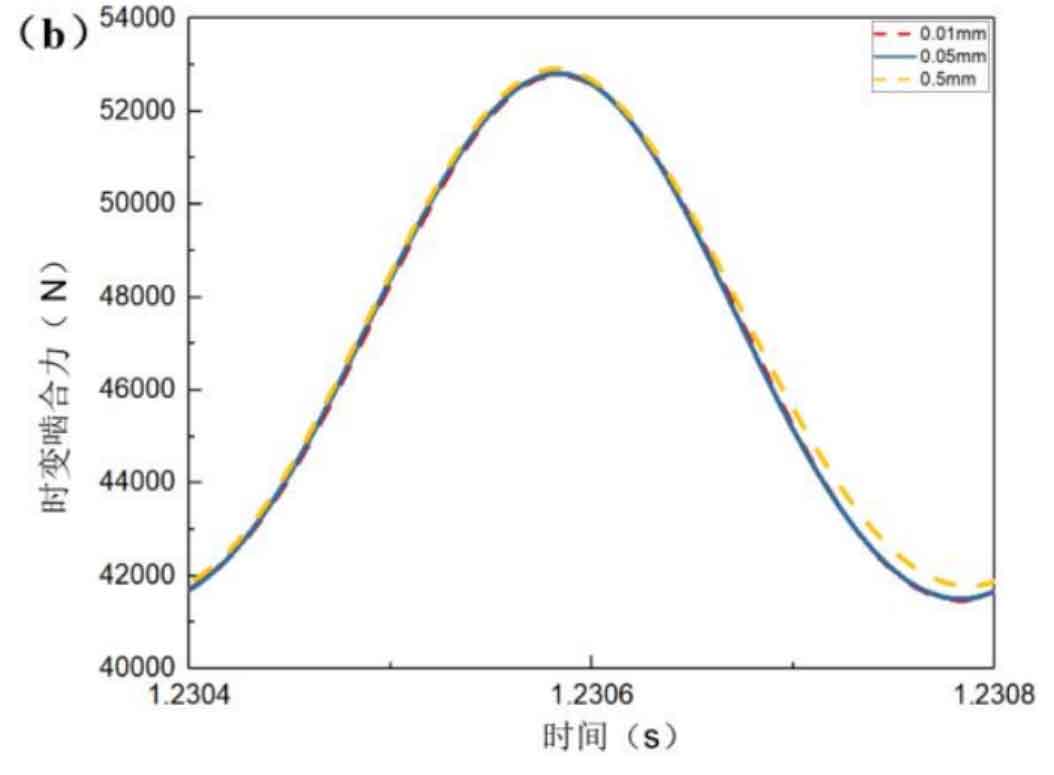

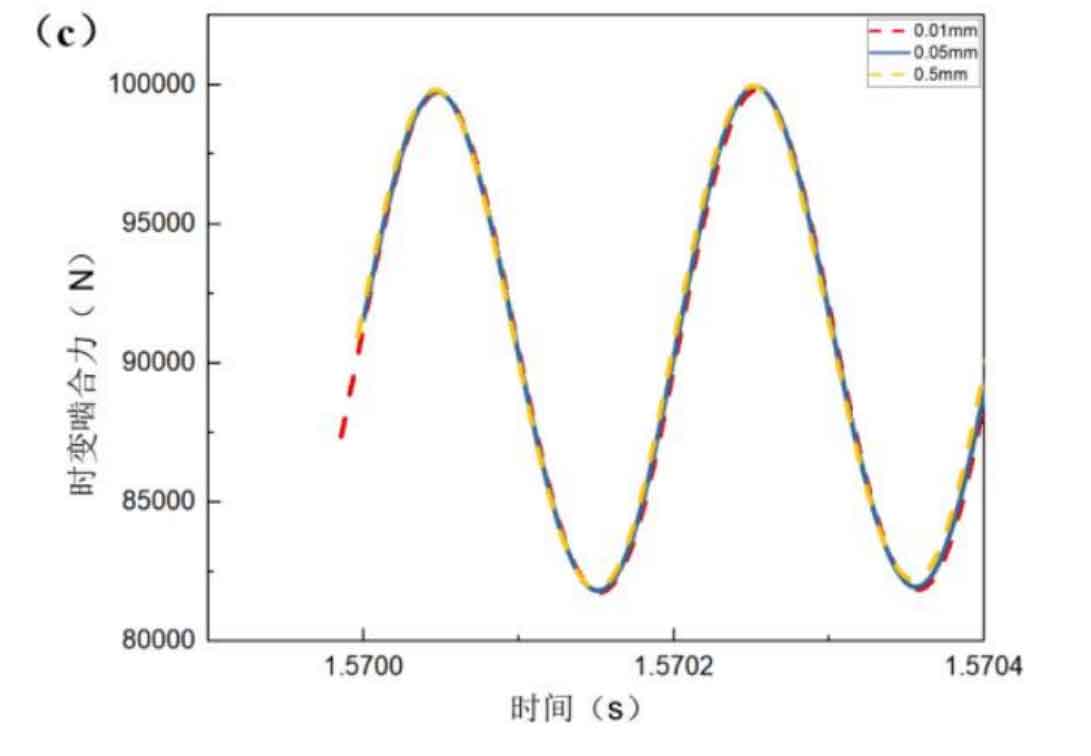

As shown in Figure 1, this is the influence curve of the tooth side clearance on the time-varying meshing force of the helical gear pair at different speeds. It can be seen that the time-varying meshing force further decreases with the reduction of the tooth side clearance, which is in line with expectations. Although for the time-varying meshing force up to tens of thousands of steps at medium and high speed (Fig. 1 (b) and Fig. 1 (c)), the influence of backlash on it is very small, only reducing the force of a few Newtons. However, it can be seen from Figure 1 (a) that proper backlash can significantly reduce the time-varying meshing force of helical gear at low speed (2000r/min), thus reducing the meshing impact excitation.

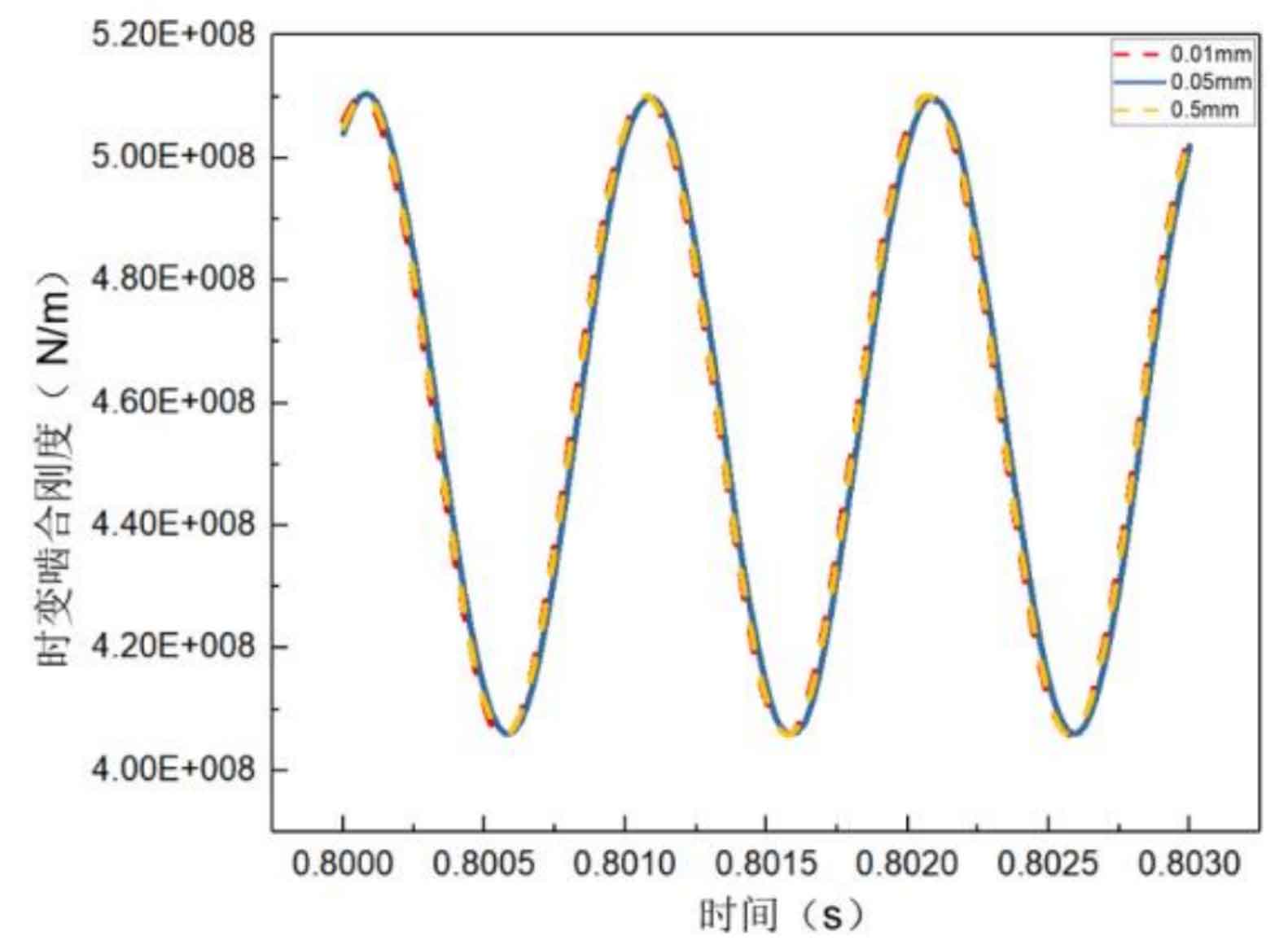

As shown in Figure 2, this is the influence curve of the backlash on the time-varying meshing stiffness of the helical gear pair. Obviously, the influence of backlash on the time-varying meshing stiffness of helical gears up to 108 grades can be ignored.

To sum up, a small backlash should be selected to reduce the dynamic excitation of helical gears without affecting the service life of helical gears, generally 0.05mm.