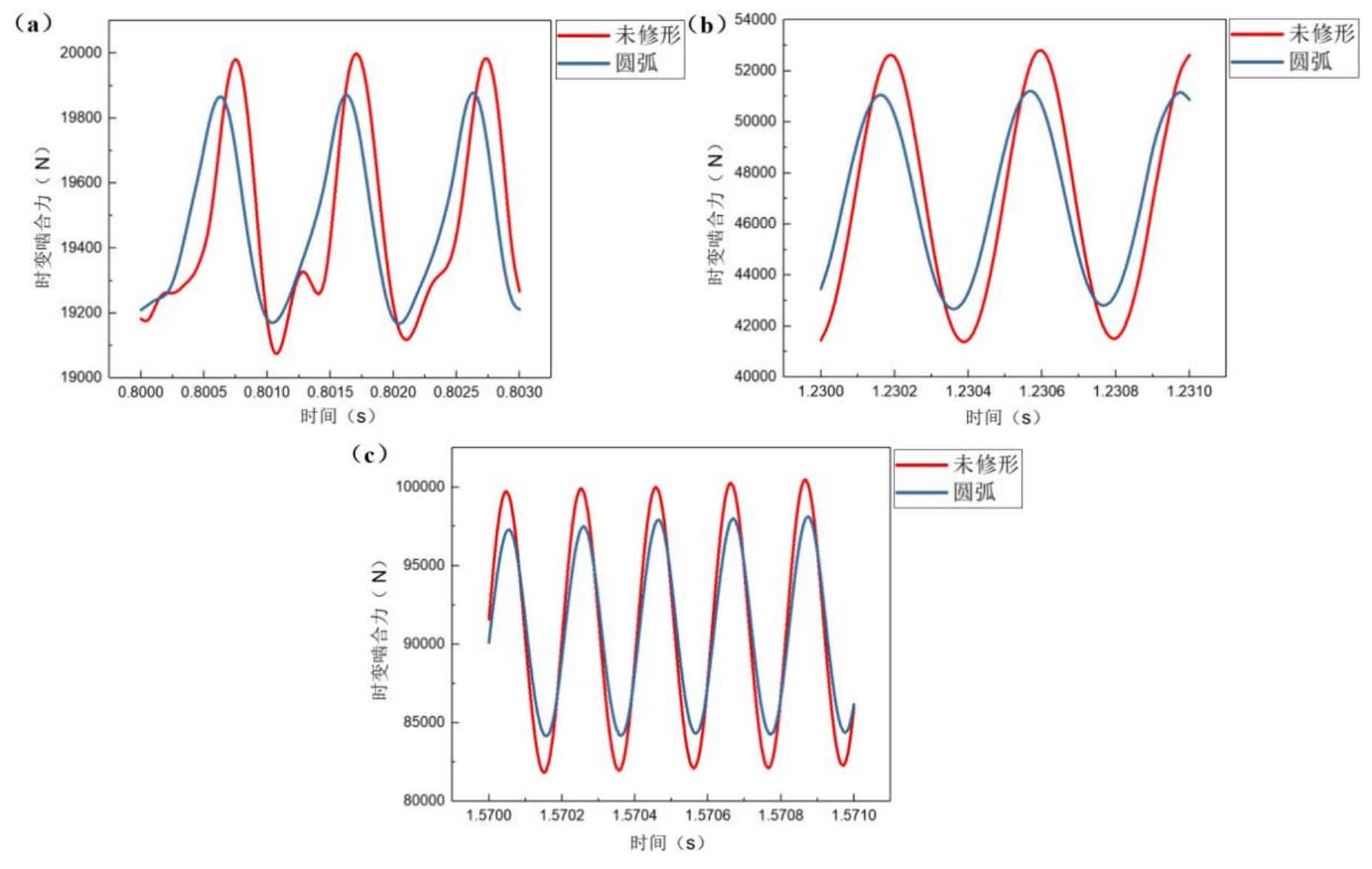

The optimized modification scheme of the long tooth profile addendum arc is the modification amount of the driving wheel 5 μ m. Modification quantity of driven wheel 4 μ m。 Figure 1 shows the time varying meshing force curves before and after the helical gear pair is optimized and modified by long tooth profile and addendum arc at different speeds. Obviously, the effect of this scheme is good, the time-varying meshing force decreases significantly under all working conditions, and the meshing impact phenomenon under low speed working conditions is eliminated, making the curve more smooth. In addition, for low speed, medium speed and high speed conditions, the peak value of time-varying meshing force changed from 199999.113N, 52794.277N and 100481.32N to 19875.703N, 51188.09N and 97988.586N respectively, which decreased by 123.41N, 1606.187N and 2492.734N respectively.

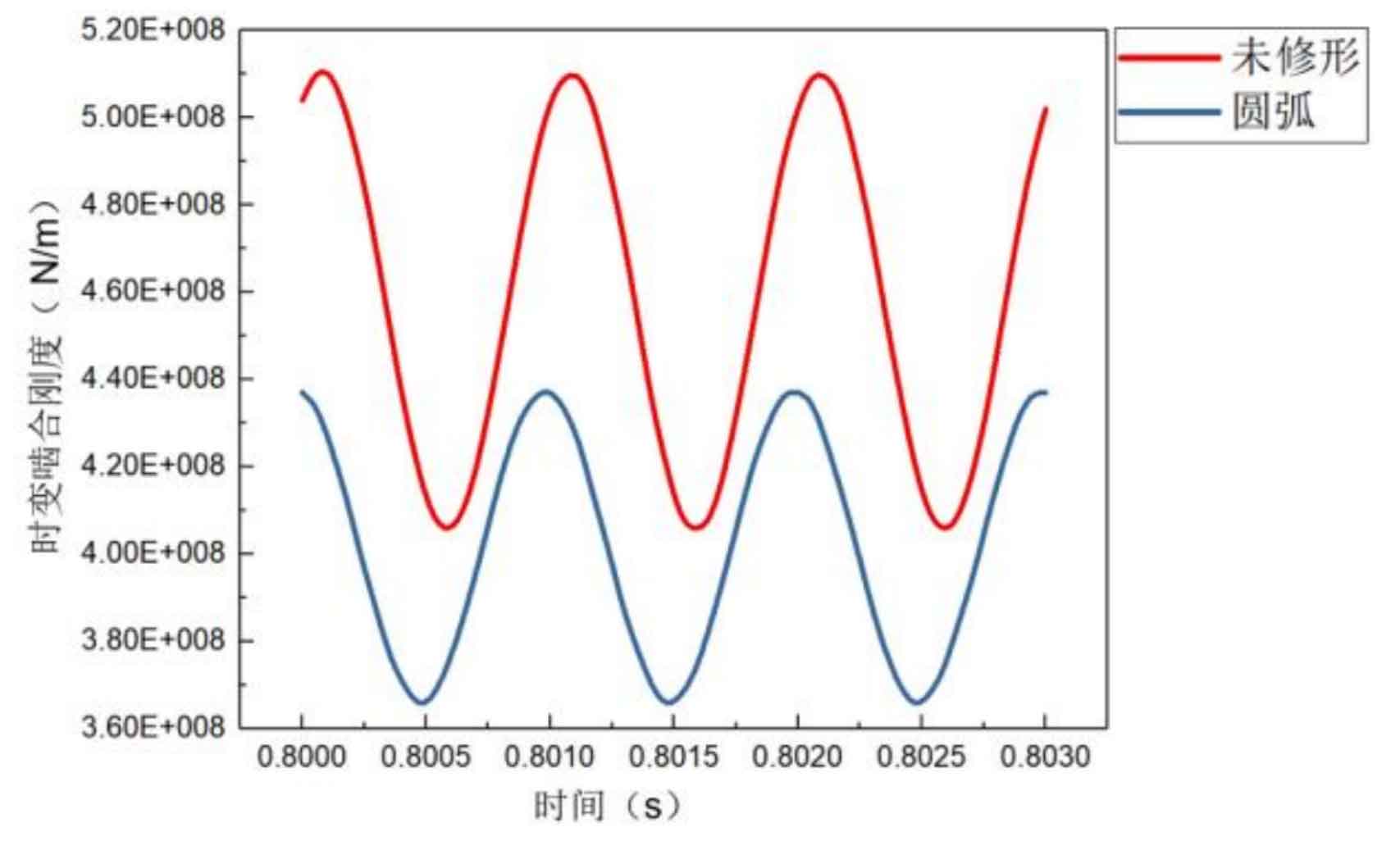

Figure 2 shows the time-varying meshing stiffness curve before and after the helical gear pair is optimized and modified by the long tooth profile addendum arc. It can be seen that this scheme significantly reduces the time-varying meshing stiffness of the helical gear pair of the reduction box of an electric vehicle. Not only does the peak stiffness increase from 5.1 before the modification × 108N/m reduced to 4.37 × 108N/m, decreased by 14.3%, and the fluctuation range also increased from 4.06 before reshaping × 108N/m~5.1 × 108N/m is reduced to 3.66 × 108N/m~4.37 × 108N/m。

Therefore, it can be considered that the dynamic excitation of the helical gear pair of the reduction box of an electric vehicle is significantly reduced, the meshing impact phenomenon disappears, and the severe vibration of the helical gear pair is effectively suppressed after the optimization and modification of the long tooth profile addendum arc.