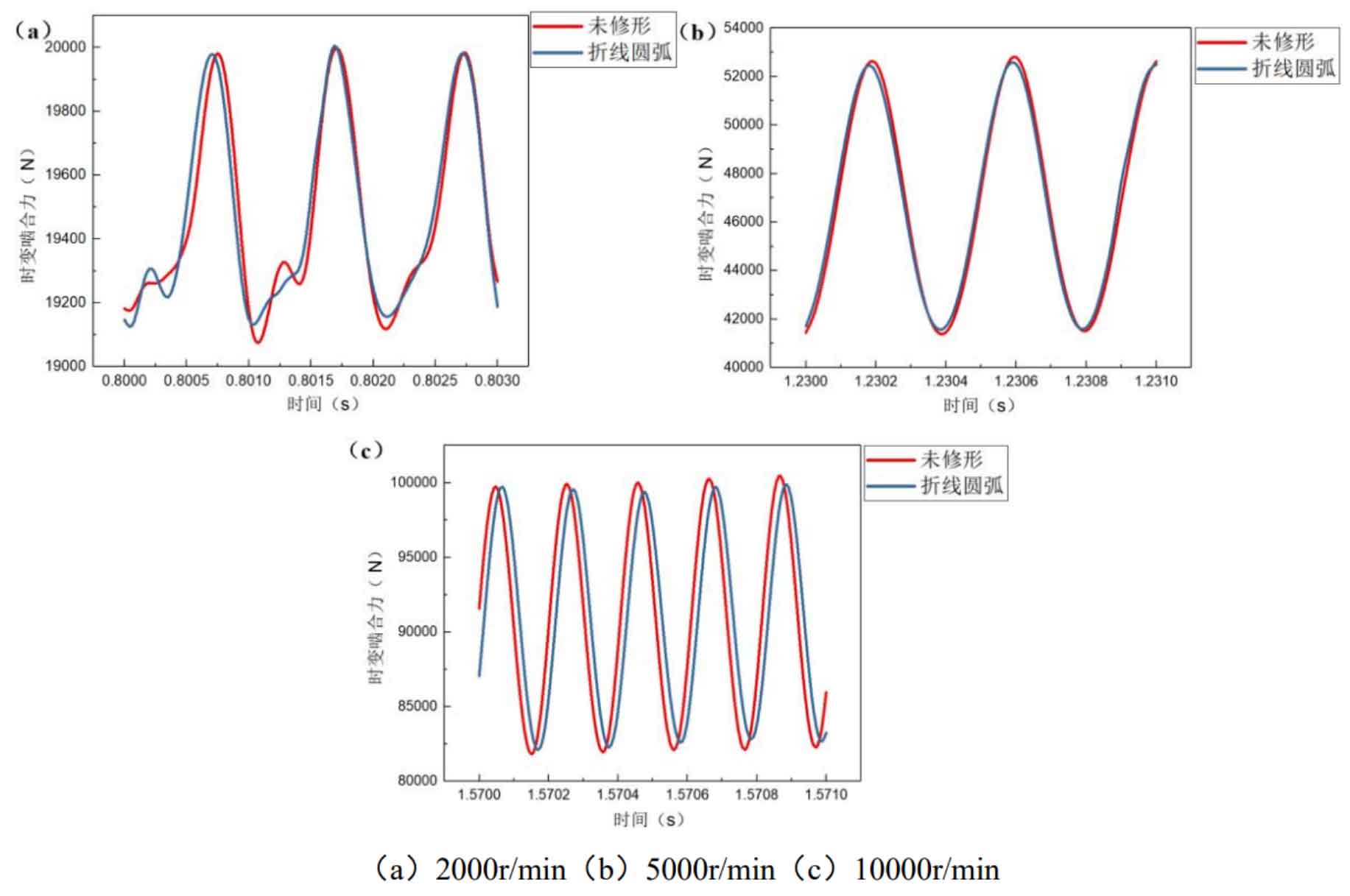

The optimized profile modification scheme of the broken line arc on the tooth top of the long tooth profile is the modification amount of the driving gear 3 μ m. Modification amount of driven wheel 3 μ m。 Figure 1 shows the time varying meshing force curves before and after the helical gear pair is optimized by the broken line arc at the top of the long tooth profile at different speeds. Although this scheme has some effect on the reduction of the time varying meshing force of the helical gear pair under medium and high speed conditions, there is still serious meshing impact phenomenon in the modified helical gear pair under low speed conditions.

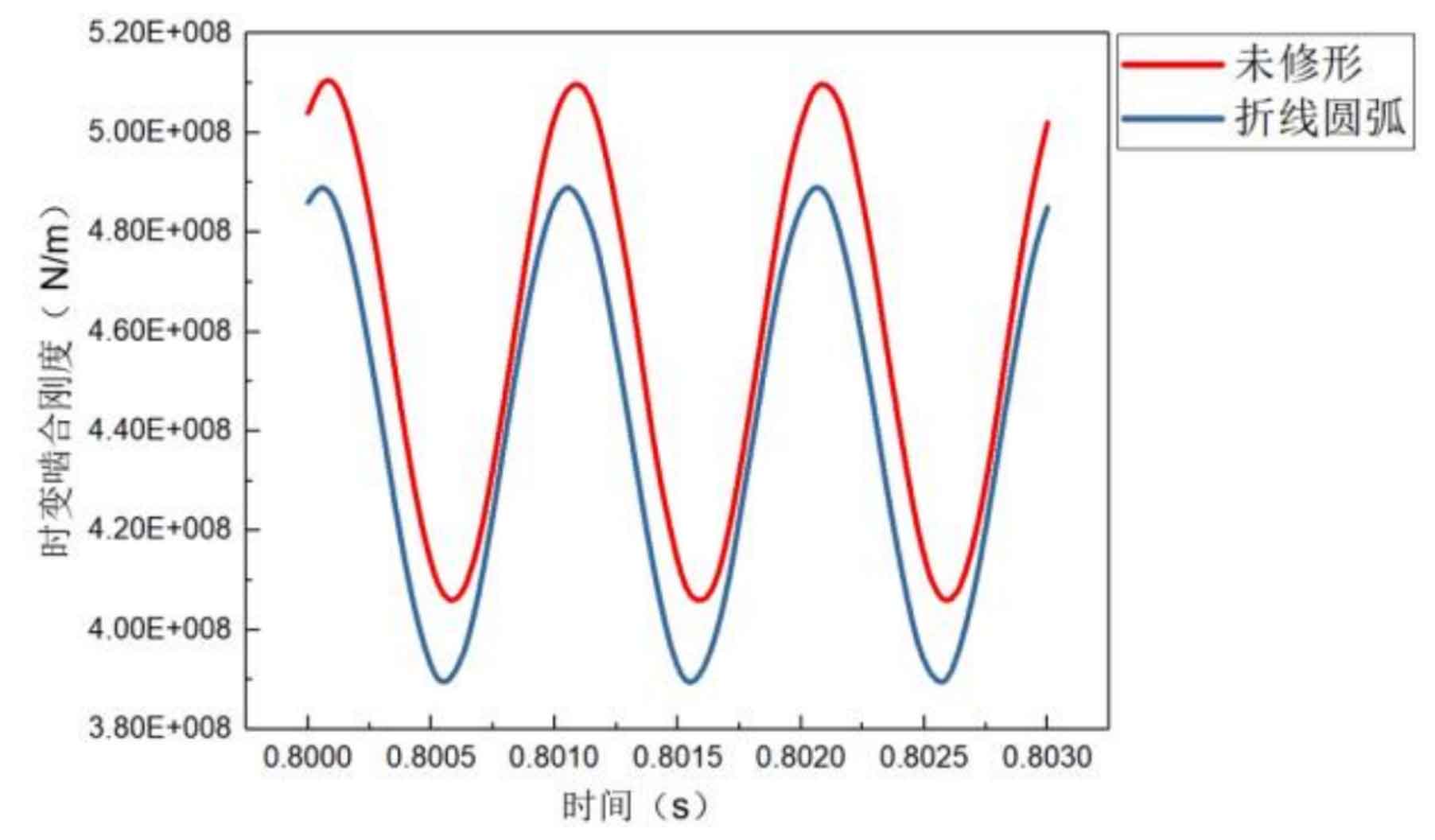

Figure 2 shows the time-varying meshing stiffness curve before and after the helical gear pair is optimized and modified by the broken line arc at the top of the long tooth profile. Obviously, the time-varying meshing stiffness of the helical gear modified by this scheme has decreased, and the peak value has decreased to 4.89 × 10 ^ 8N/m, with a decrease of 4.1%.

Therefore, on the whole, it can only be said that the internal dynamic excitation of the helical gear pair of an electric vehicle reducer has improved after the optimization and modification of the broken line arc at the top of the long tooth profile, and the degree of gear vibration and meshing impact has been alleviated to a certain extent.