Because the red lead powder will condense into blocks when it meets the engine oil, which will interfere with the judgment of the test results and even affect the entire helical gear pair transmission, here the pinion is rotated at 1000r/min on the built helical gear box test bench, and the distribution of the red lead powder on the tooth surface of the two pairs of helical gear pairs before and after the experience modification is observed after the same time (without engine oil), To judge the load on the tooth surface of the actual two pairs of helical gears during transmission.

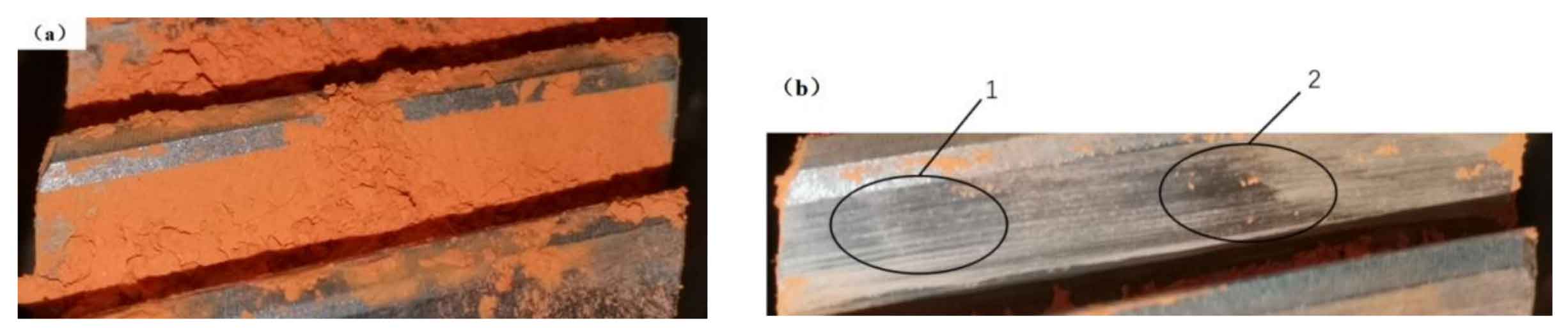

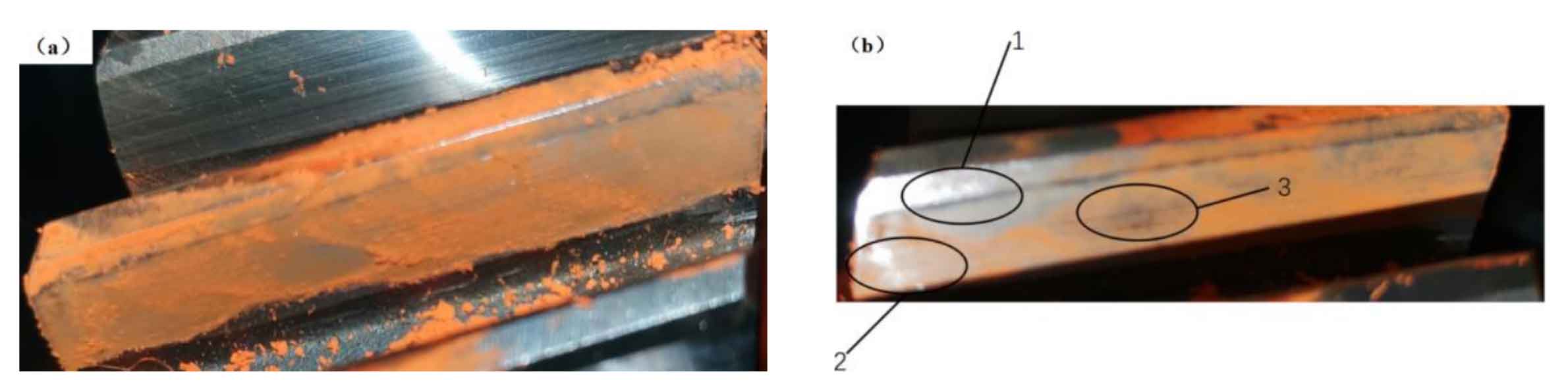

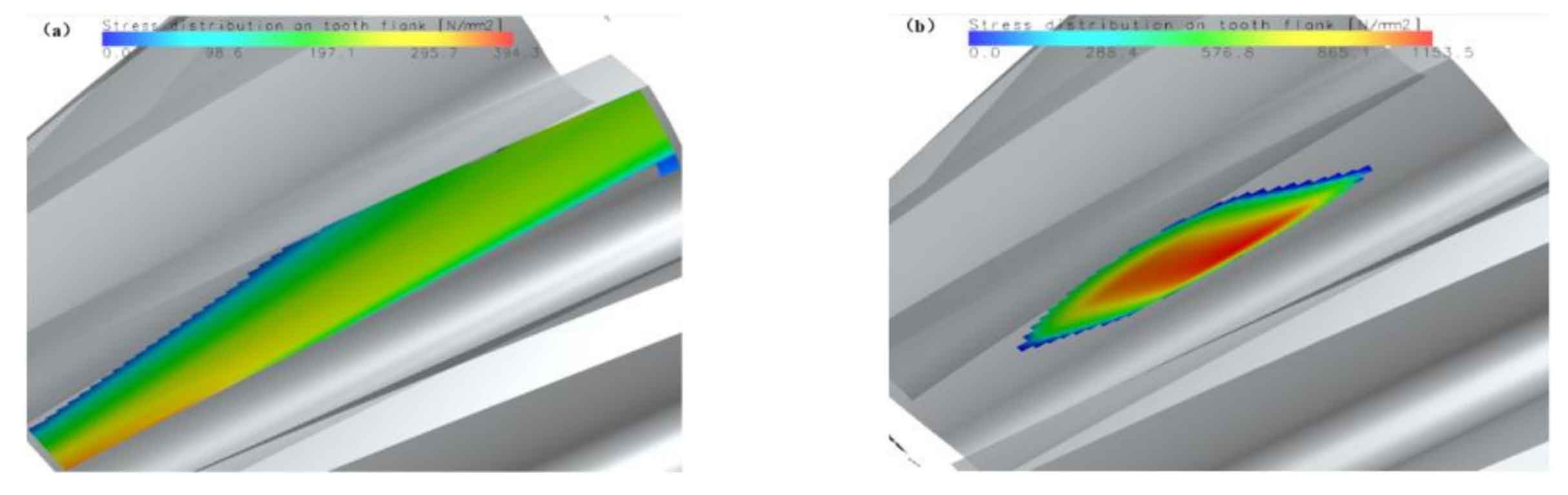

However, because the KISSsoft simulation condition is oil bath lubrication, there will be a little error between the test results and the simulation. It can be seen from Figure 1 that the red lead powder at 1, 2 and 3 places on the tooth surface of the unmodified helical gear pair has fallen off seriously, which indicates that these places bear a large load when the helical gear is engaged and driven, which is basically consistent with the simulation results of the serious off-load at the lower left corner of the gear tooth shown in Figure 2 (a).

Looking at Figure 3, it is found that one and two places on the tooth surface of the helical gear after empirical modification bear a large load, which is also basically consistent with Figure 2 (b). If we further analyze the wear of red lead powder, we can find that the two red lead powder on the tooth surface of the helical gear after the modification are almost polished, which verifies the conclusion that the blind experience modification obtained in the previous section will aggravate the tooth surface wear of the helical gear pair and greatly reduce its service life.