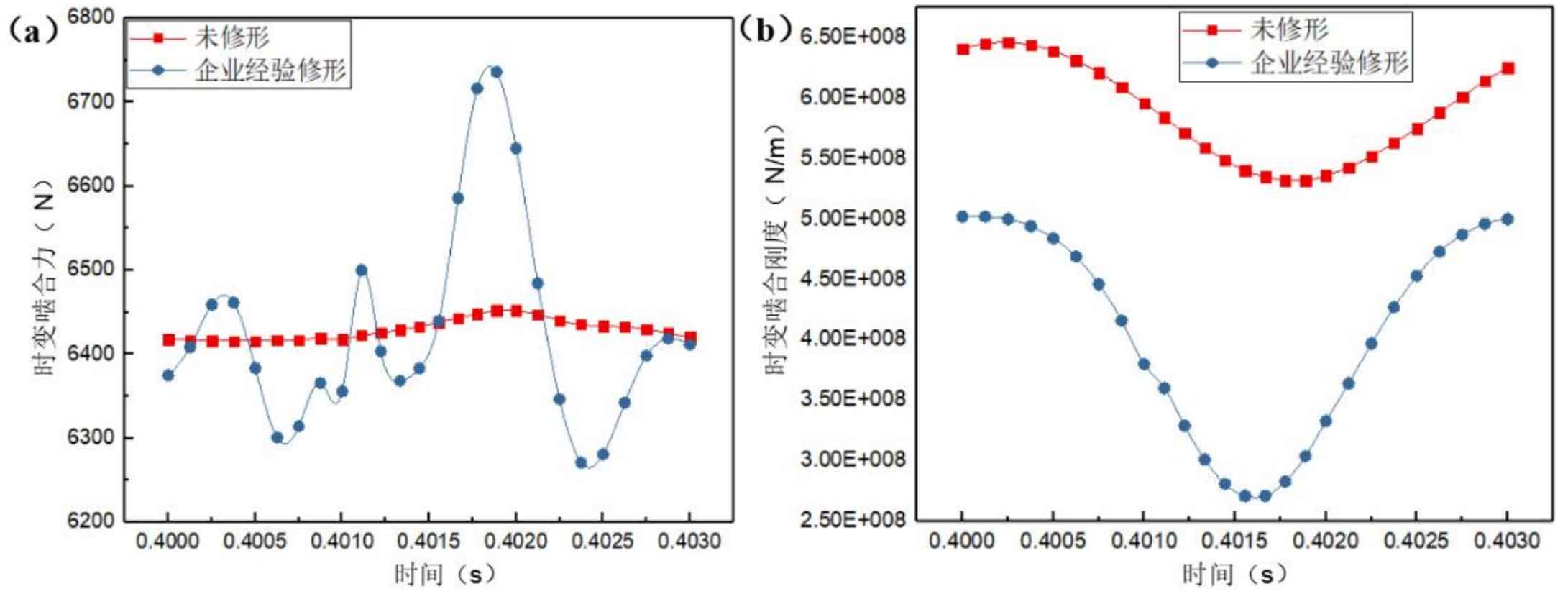

As shown in Figure (a), the time-varying meshing force curve of the helical gear product of a certain enterprise before and after the experience modification can be seen that the time-varying meshing force of the helical gear pair after the experience modification has increased significantly and the curve is more tortuous, which indicates that the internal excitation of the helical gear has increased, and the meshing impact is easy to occur, resulting in the sharp vibration and abnormal noise of the helical gear pair. Figure (b) shows the time-varying meshing stiffness curves before and after the empirical modification of the existing helical gear products of an enterprise. Although the empirical modification greatly reduces the time-varying meshing stiffness value of the helical gear pair, its fluctuation range is significantly increased.

To sum up, the traditional empirical modification scheme is not effective for all helical gear pairs. Because the transmission error and time-varying meshing force of the helical gear pair are significantly improved after the empirical modification, and the time-varying meshing stiffness fluctuates more, which intensifies the vibration between the helical gear pairs during meshing, and finally leads to the increase of the helical gear noise.