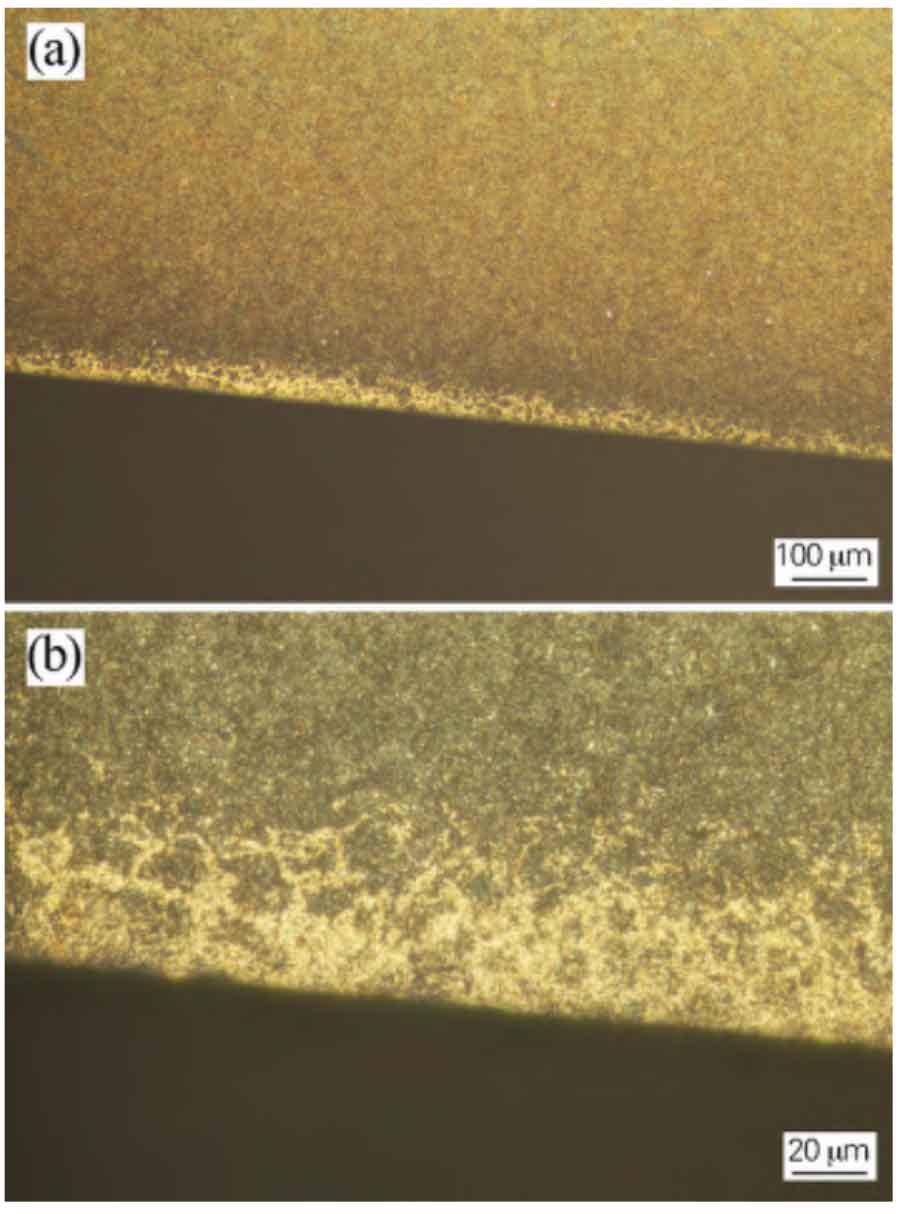

It can be seen from Figure 1 that there is a relatively obvious white and black grinding burn zone at the root of the tooth near the crack on the convex surface of the spiral bevel gear tooth profile sample. When viewed at a magnification of 500 times, as shown in Figure 1 (b), there are dark undissolved structures in the white zone, which is slightly different from the characteristics of the typical grinding burn zone, indicating that the white burn zone generates grinding heat during grinding, making the surface temperature exceed the phase change point Ac1 of the material, However, the phase transformation point Accm, which is not fully austenitized, is re-quenched in the two-phase zone between Ac1 and Accm, forming this incomplete quenched structure.

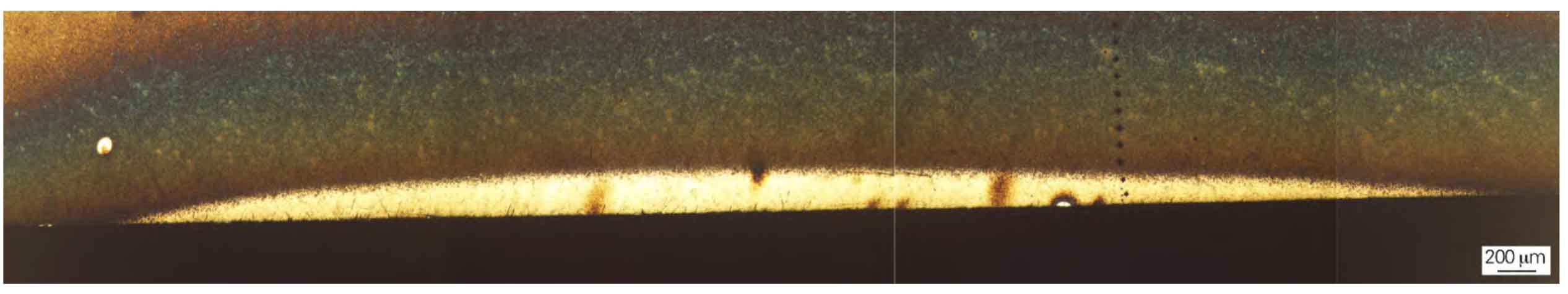

The microstructure of the convex surface crack of the spiral bevel gear tooth profile sample is shown in Figure 2, showing an obvious crescent-shaped white and black grinding burn appearance. The white area is due to the improper grinding process, which produces high grinding heat, and re-quenches the carburized surface into quenched martensite and retained austenite. The structure has high hardness and corrosion resistance. The maximum surface hardness is 820 HV0.1, and the maximum depth of the white area is about 0.3 mm; From the white area to the inside, next to the white area is the black over-tempered area caused by grinding heat. This area is softened by grinding heat tempering. The minimum hardness is about 486 HV, the hardness drops sharply, and the width of the black area is about 0.6 mm. From the black area to the center, the microhardness of the carburized layer decreases to different degrees compared with the unburned area at the pitch circle of the uncracked tooth surface.

Observe the microstructure at the place where the convex surface of the spiral bevel gear tooth profile sample without grinding burn is far away from the crack pitch circle, as shown in Figure 3. It can be seen that the surface structure of the carburized layer is good. According to JB/T 6141.3-1992 “Carburizing Metallographic Examination of Heavy-duty Gears”, the martensite and residual austenite on the carburized layer surface are grade 1 to 2, and the carbide is grade 1 to 2; The heart tissue is grade 1-2. Qualified.