The contact stress of the tooth surface of the circular tooth line cylindrical gear is closely related to the tooth width and tooth line radius, and under the same conditions, the contact strength of the circular tooth line cylindrical gear pair is significantly higher than that of the spur gear and helical gear. This paper studies the influence of different tooth width and tooth line radius on the contact stress of the gear tooth surface under the same conditions, and analyzes and summarizes the contact stress of the gear using ANSYS Workbench.

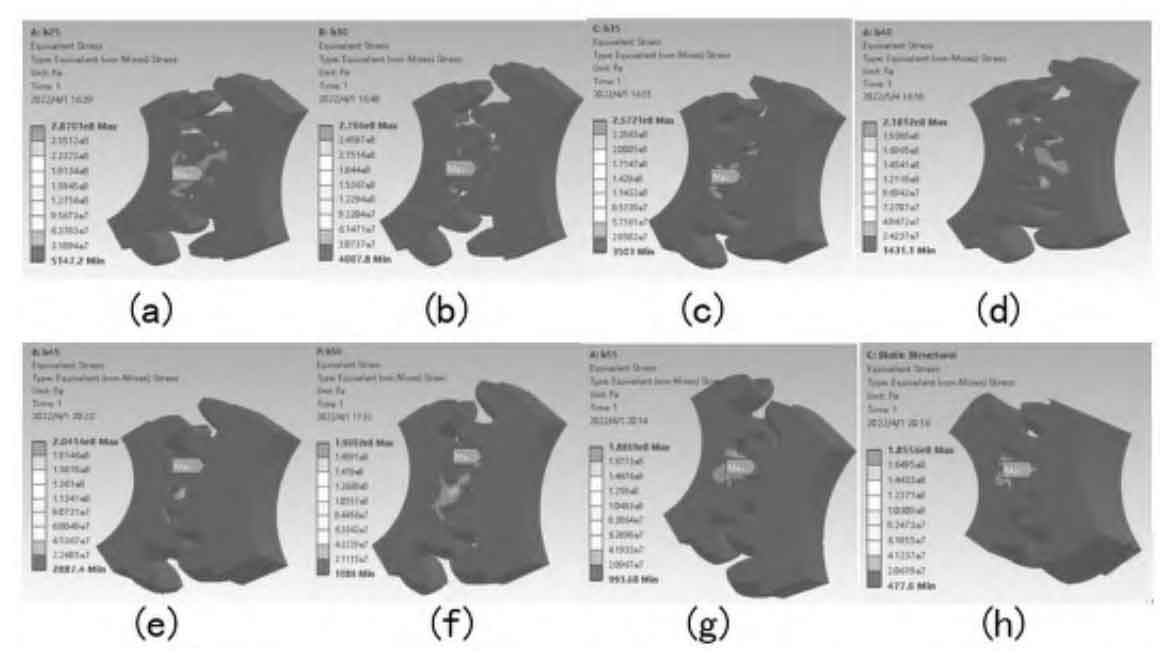

In order to analyze the influence of tooth width on the contact stress of cylindrical gears with circular tooth profile, eight groups of gear pairs with different tooth width coefficients are selected for contact stress analysis Φ A is the ratio of the width to the center distance of the cylindrical gear with circular tooth profile. Other parameters are listed in Table 1. Import the established model of circular tooth line cylindrical gear pair into ANSYS Workbench to analyze the contact stress of the gear pair. The default material is structural steel, and the elastic modulus is 2 × 1011 Pa, Poisson’s ratio is 0.3, applied torque of pinion T=200 N . m, tooth surface contact type is friction contact, friction coefficient is 0.05, and eight groups of gear tooth contact stress nephogram are obtained, as shown in Figure 1.

| Gear pair number | Tooth width coefficient | Tooth width/mm | Contact stress value/MPa |

| a | 0.25 | 25 | 287.01 |

| b | 0.30 | 30 | 276.60 |

| c | 0.35 | 35 | 257.21 |

| d | 0.40 | 40 | 218.12 |

| e | 0.45 | 45 | 204.14 |

| f | 0.50 | 50 | 190.02 |

| g | 0.55 | 55 | 188.69 |

| h | 0.60 | 60 | 185.56 |

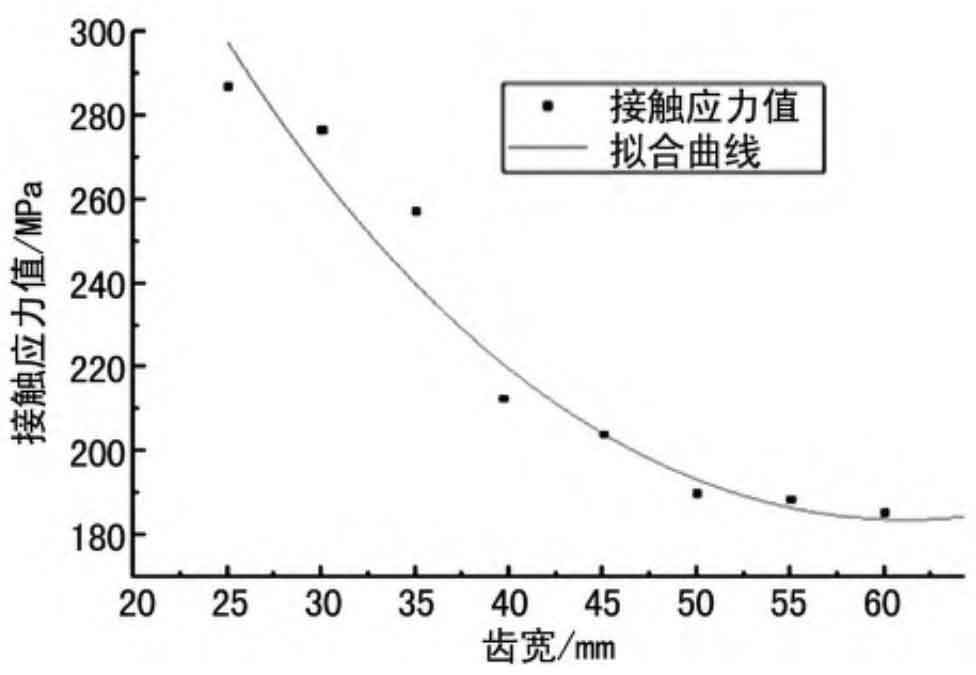

Figure 1 (a)~(h) correspond to the contact stress of 8 groups of circular tooth profile cylindrical gear pairs with different tooth width coefficients under torque T=200 N.m. The contact stress values are listed in Table 2. Fit the contact stress values of circular tooth profile cylindrical gears with different tooth widths, and the resulting curve is shown in Figure 2.

In Figure 2, when the tooth number z, modulus m, tooth line radius R and pressure angle of circular arc tooth line cylindrical gear α When the equal parameters are fixed, the load carrying capacity of the circular tooth profile cylindrical gear will increase with the increase of tooth width b in a certain range. But when the tooth width coefficient Φ When a is greater than 0.6, the contact stress on the tooth surface begins to increase, and the load distribution along the tooth width begins to be uneven, which is easy to cause the phenomenon of eccentric load and stress concentration, so that the actual bearing capacity of the circular tooth line cylindrical gear decreases.