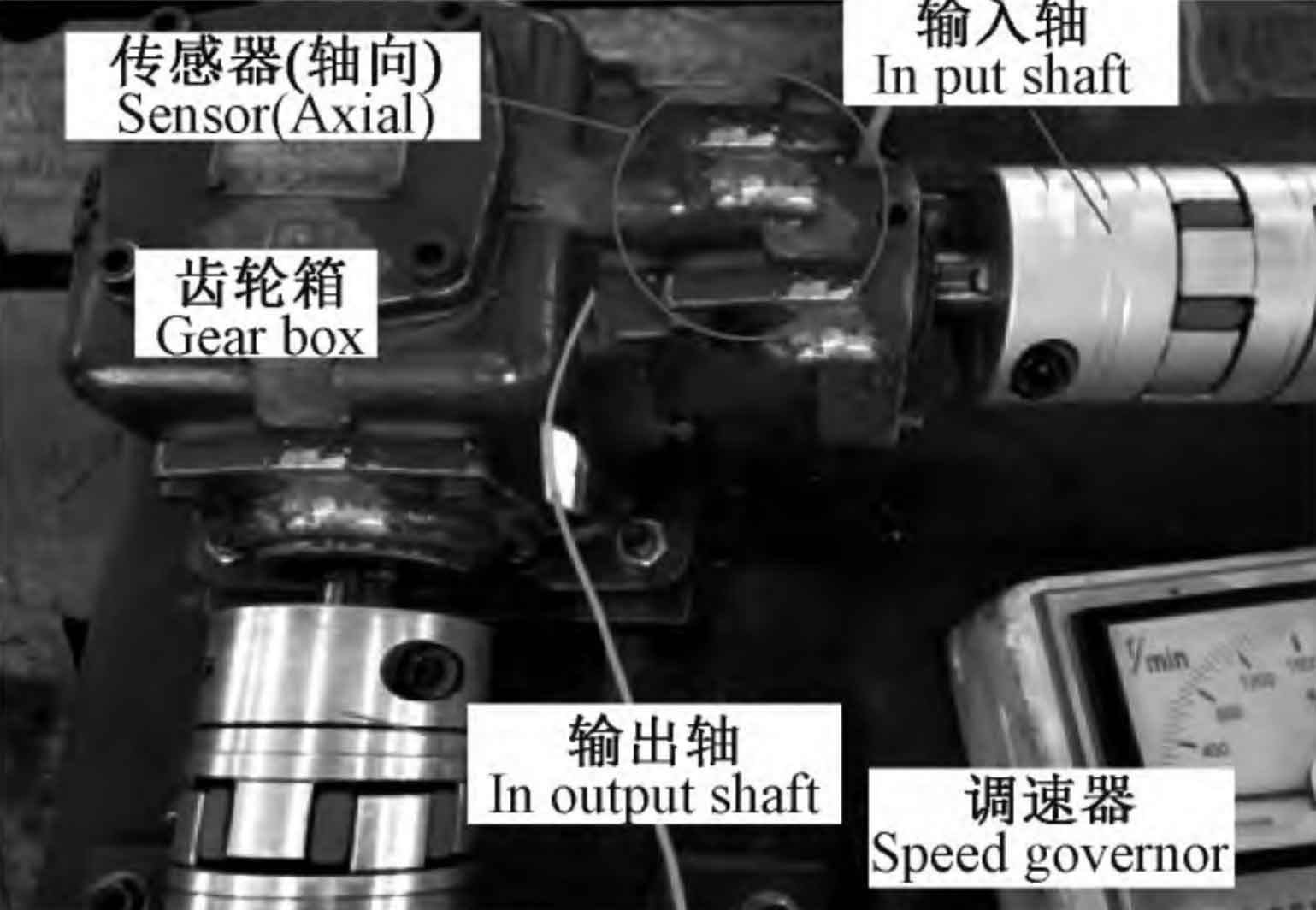

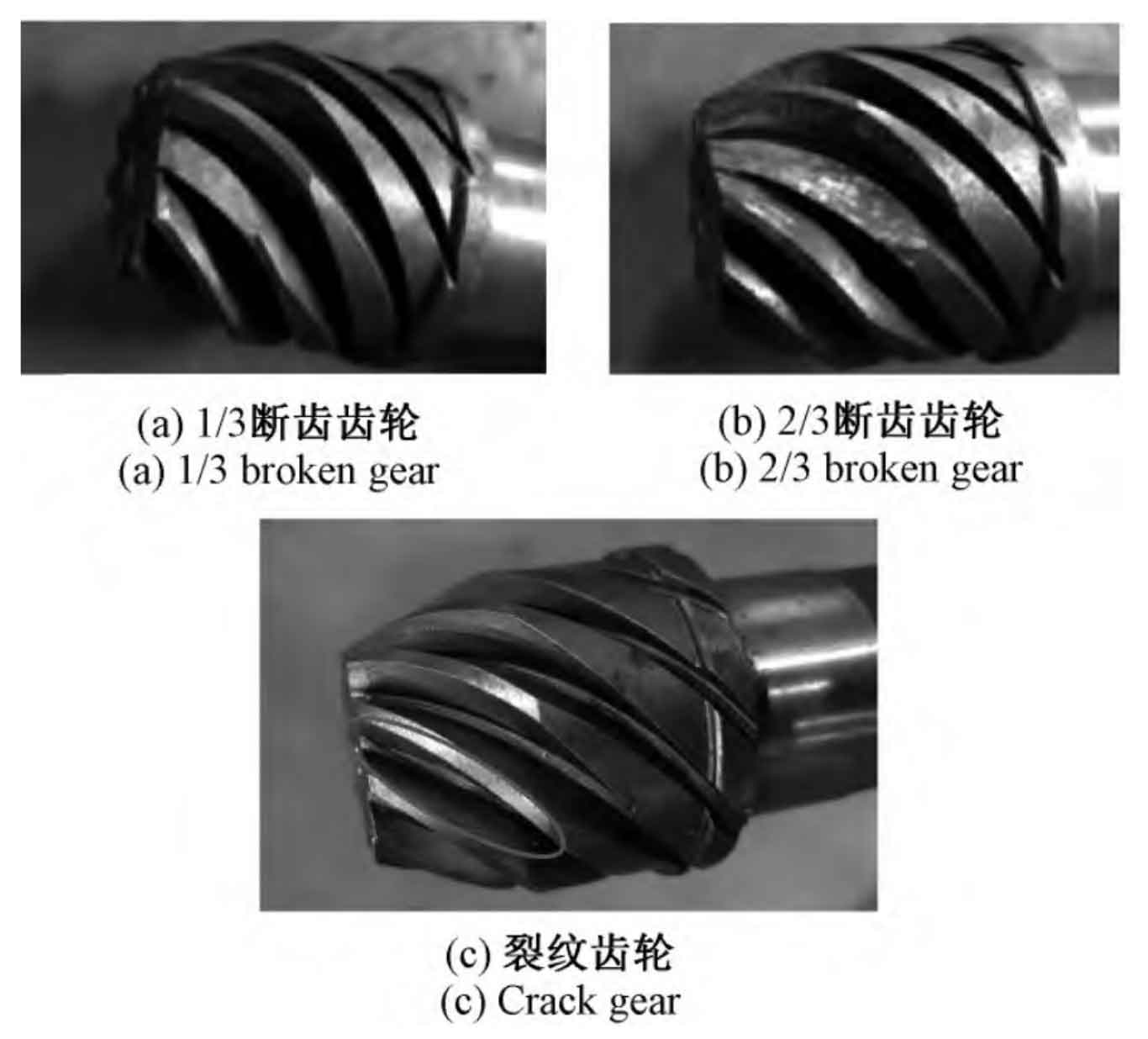

In order to verify the effectiveness of the method, the vibration simulation test of spiral bevel gear broken tooth fault was carried out, which was carried out on the comprehensive simulation platform of spiral bevel gear system fault, as shown in Figure 1. According to the different degree of tooth breakage, two different degrees of tooth breakage failure, root crack failure and fault-free spiral bevel gears are set, as shown in Figure 2. The faulty spiral bevel gear is set on the input shaft, and the acceleration sensor is installed on the input shaft. The BK test system is used to collect the vibration signal. The sampling frequency is set to 8 192 Hz. In the test, the input speed is set to 1200 r/min. The vibration signals under normal condition, 1/3 broken tooth condition, 2/3 broken tooth condition and root crack condition were collected in the test.

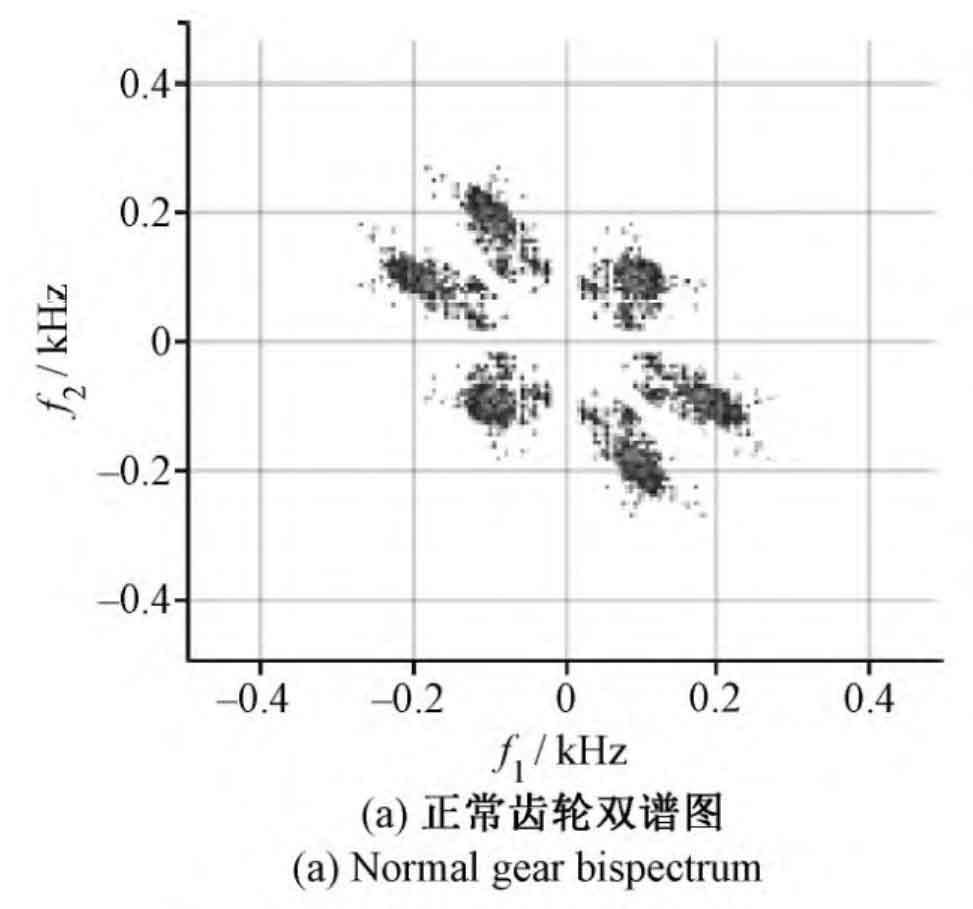

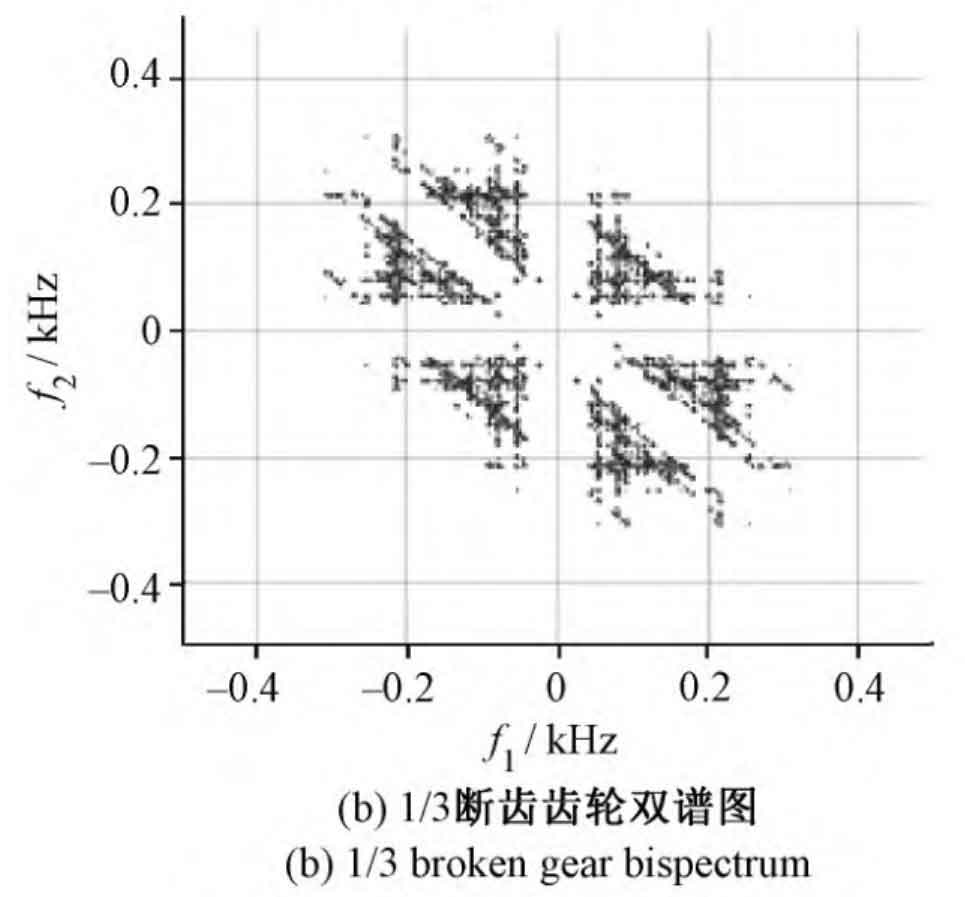

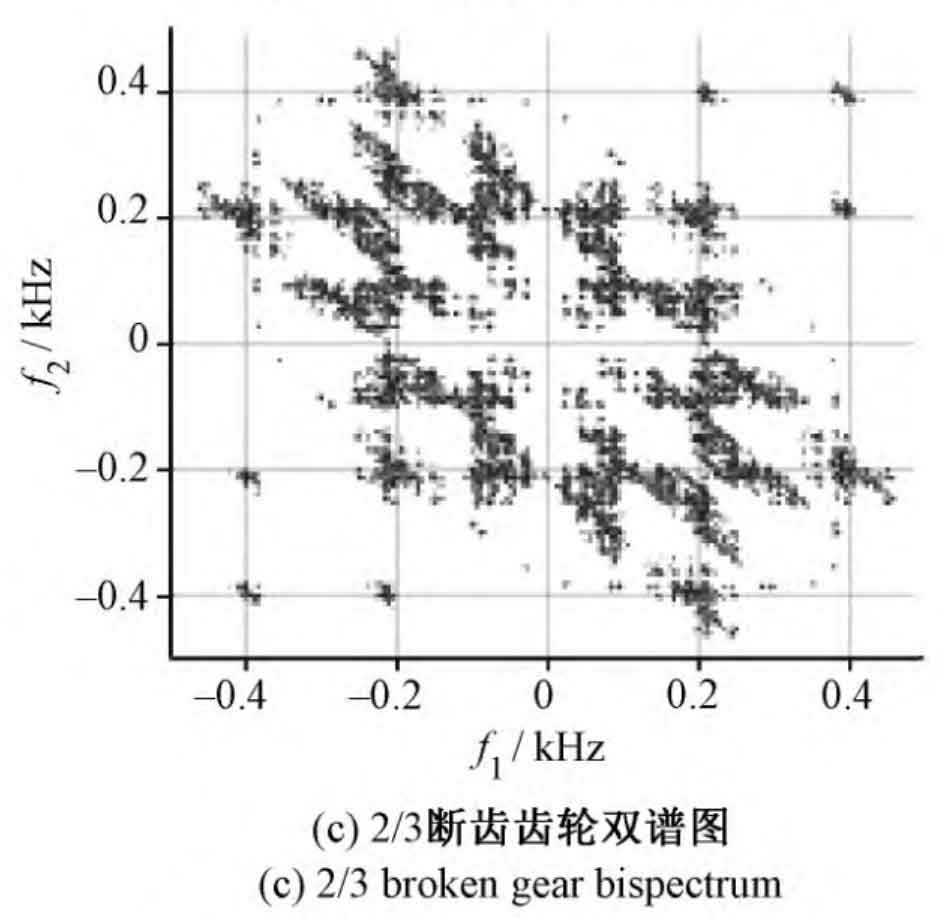

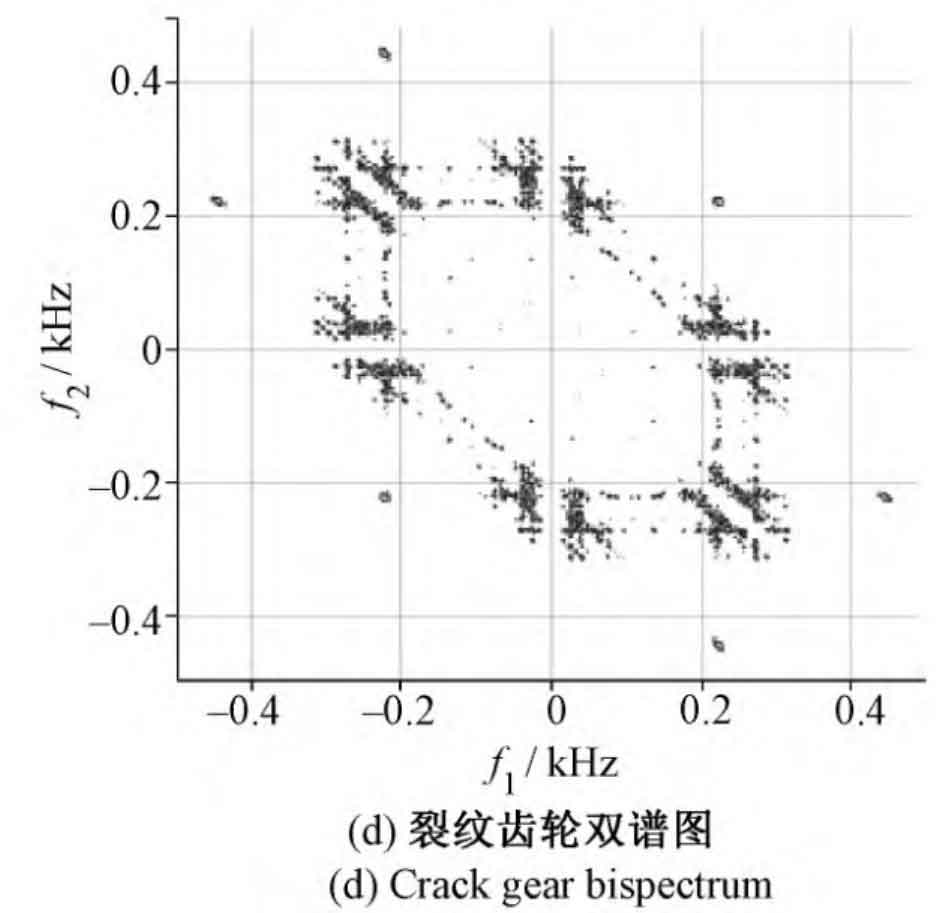

The vibration signal collected under each state is divided into several data segments with a length of 1024, and bispectral analysis is carried out for each data segment to obtain its bispectral diagram. The two-dimensional bispectrum of spiral bevel gears with different fault types is shown in Figure 3.

Intercept 1/4 bispectrum to obtain its local bispectrum with the size of 128 × 128 pixels to build a CNN sample. A total of 500 sets of fault samples were obtained from the test, and a total of 2000 samples were obtained from 4 different operating conditions of spiral bevel gears.