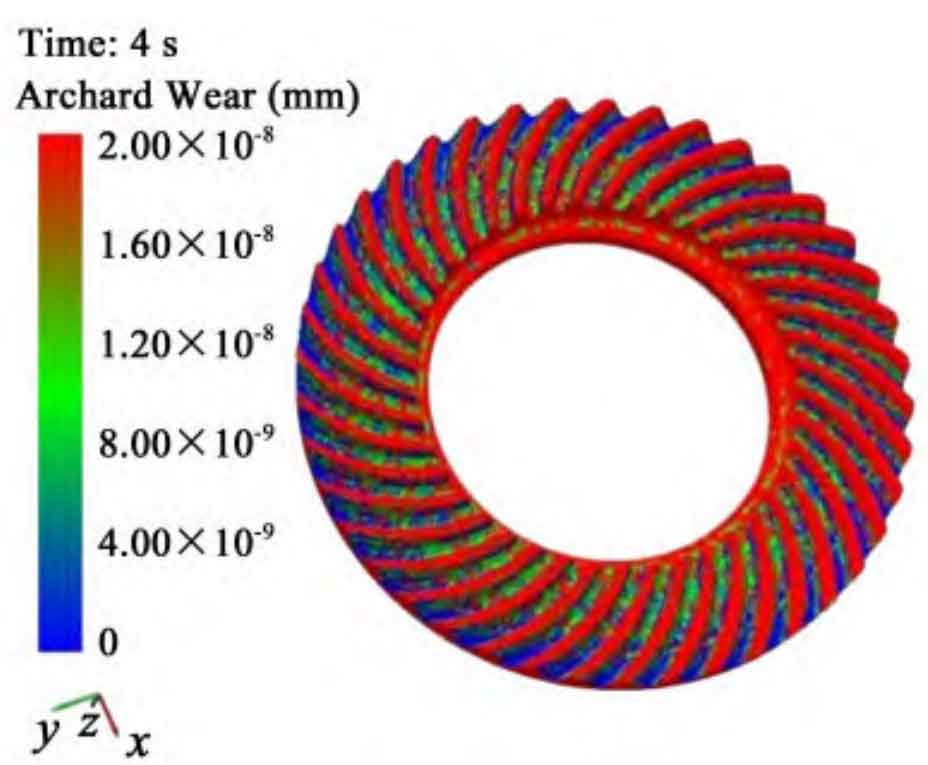

The Hertz-Mindlin with ar ⁃ chart wear model included in the EDEM software is used to simulate the wear amount of the spiral bevel gear during hobbing and polishing, as shown in Figure 1.

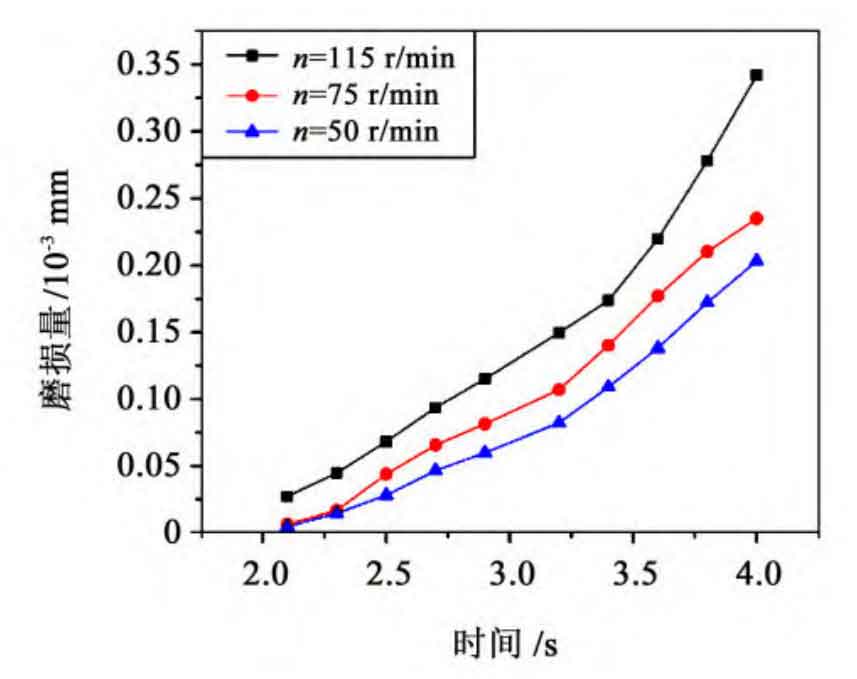

Because the disc spiral bevel gear is inversely tapered, the small end wear is large. Change the spindle speed to n=115 r/min, n=75 r/min, n=50 r/min for multi-group simulation. After the simulation, enter the software post-processing tool module, and the extraction time is 2 The wear amount of internal spiral bevel gear workpiece from 1 s to 4 s is shown in Figure 2.

It can be seen from Figure 2 that the wear amount of spiral bevel gear is positively correlated with time. With the higher the spindle speed, the difference between the spindle speed and the barrel speed will increase, and the impact force of the workpiece in the abrasive will increase, so the wear amount will increase, and the simulation results are consistent.