1. Experimental conditions

The experiment adopts a parallel spindle type finishing platform, and the workpiece to be processed is a pair of spiral bevel gears. The specific parameters of spiral bevel gears are: modulus m=4 4 mm, tooth number of cone plate z2=41, midpoint helix angle β= 35°。 The material of spiral bevel gear is 20Cr2Ni4A. The average hardness of tooth surface of spiral bevel gear is 59 2 HRC。 The roller diameter is 1260 mm, the abrasive material is corundum, and the diameter is 2 mm ball shaped material. The filling amount is 70% of the volume of the drum, and the abrasive is mixed by water and polishing fluid in a certain proportion. In the experiment, the mixing proportion and abrasive flow are guaranteed to be fixed. The spiral bevel gear is installed on the specific tooling, the distance between the tooling rotation center and the drum rotation center is 410 mm, and the depth of the spiral bevel gear immersed in the abrasive during processing is 150 mm. In order to ensure the consistency of machining on both sides of the tooth profile, the forward and reverse time of the workpiece is consistent during the machining process, and the rotation of the drum and the rotation of the workpiece are always opposite.

2. Finishing effect

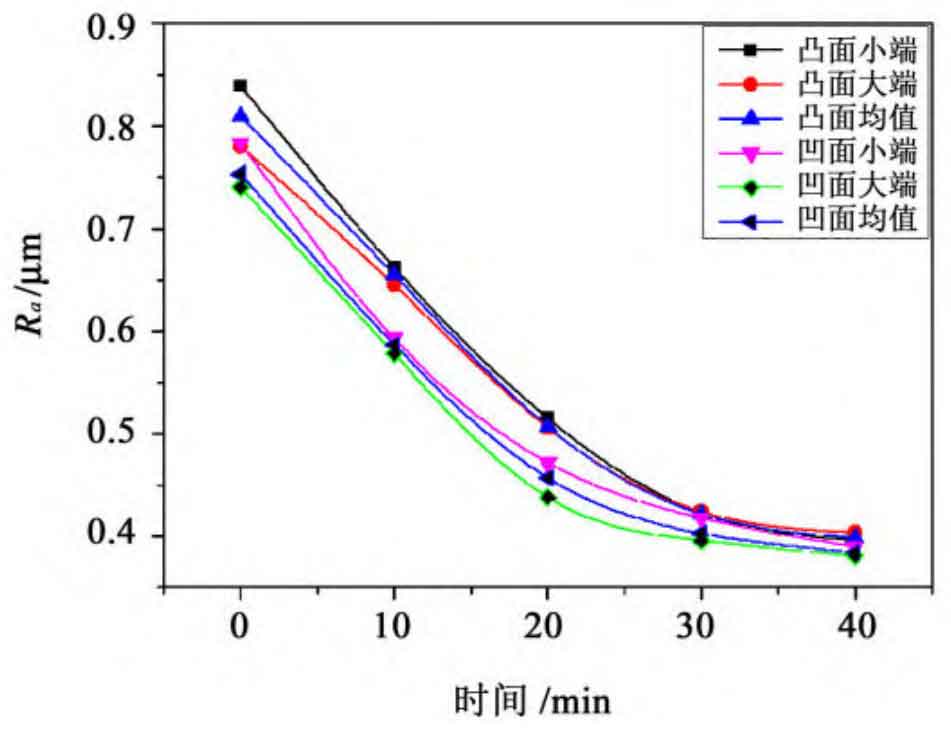

The tooth surface roughness is measured by the contact roughness meter of a company, which can measure the arc surface roughness. During the machining process, the tooth surface roughness value shall be measured every 6 minutes, and the average value shall be taken after three measurements at the same position. In order to reduce the measurement error, the measuring fixture of the spiral bevel gear is specially designed and manufactured, and the small indexing plate is used to ensure the accuracy of the measuring position of the tooth surface, as shown in Figure 1. The tooth surface roughness Ra is from 0 eight μ M to 0.4 μ The variation of tooth surface roughness value with time is shown in Figure 1.

It can be seen from Figure 1 that before finishing, the roughness value of the convex surface of the spiral bevel gear is greater than that of the concave surface. Due to the large number of teeth of the spiral bevel gear and the small gap between the teeth slots, the concave surface is affected by the “vortex gathering” phenomenon of particles during the machining process, the number of abrasives collided is increased, and the wear amount is increased, so the slope of the concave surface roughness is large at the initial stage. That is, under the same conditions, the machining efficiency of concave surface is higher than that of convex surface, but with the increase of time, the roughness curve tends to be flat, indicating that the convex peak of the tooth surface has been basically smoothed, and the hobbing process can be terminated.

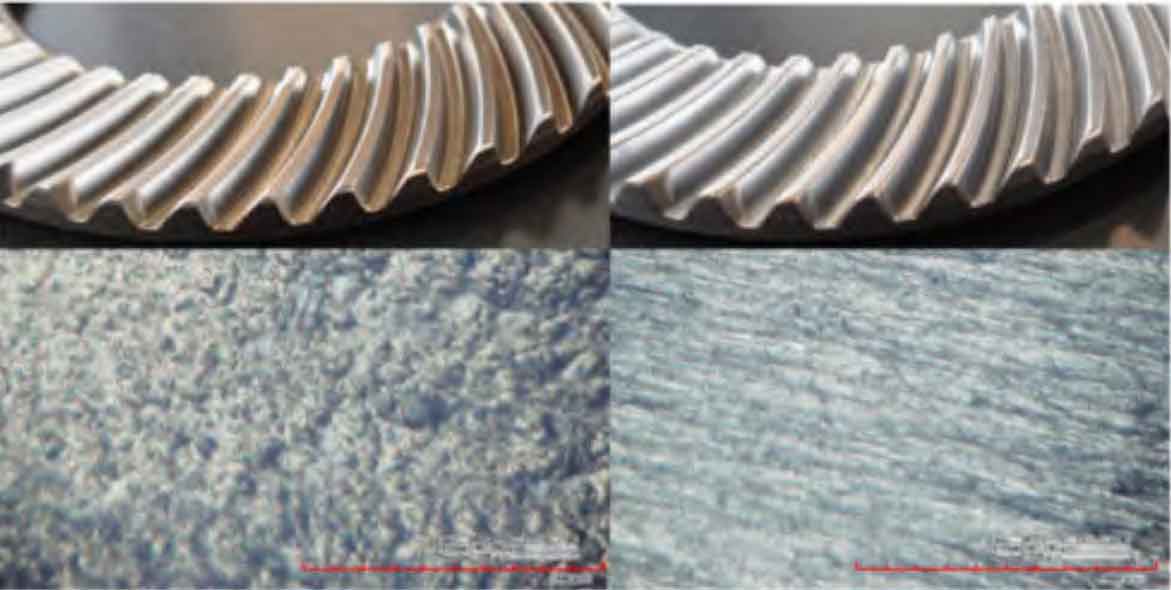

The comparison before and after the disc spiral bevel gear hobbing and finishing is shown in Figure 3. After hobbing, the surface brightness of the spiral bevel gear increases, the burr at the tooth top and the outer circle is removed, and the grinding trace of the tooth surface and the tooth groove is reduced. The digital 3D video microscope magnifies the cutting tooth surface by 140 times, and it can be seen that the quality of the tooth surface is significantly improved after finishing.