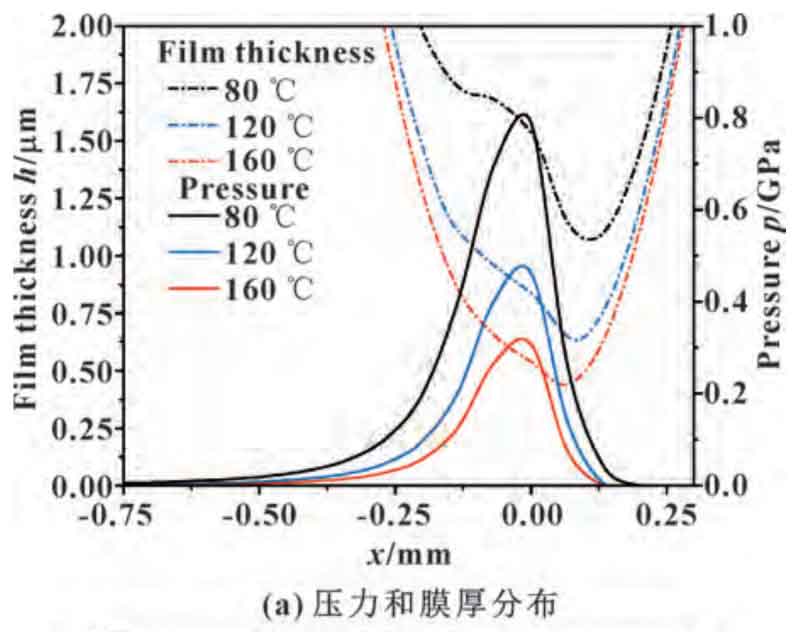

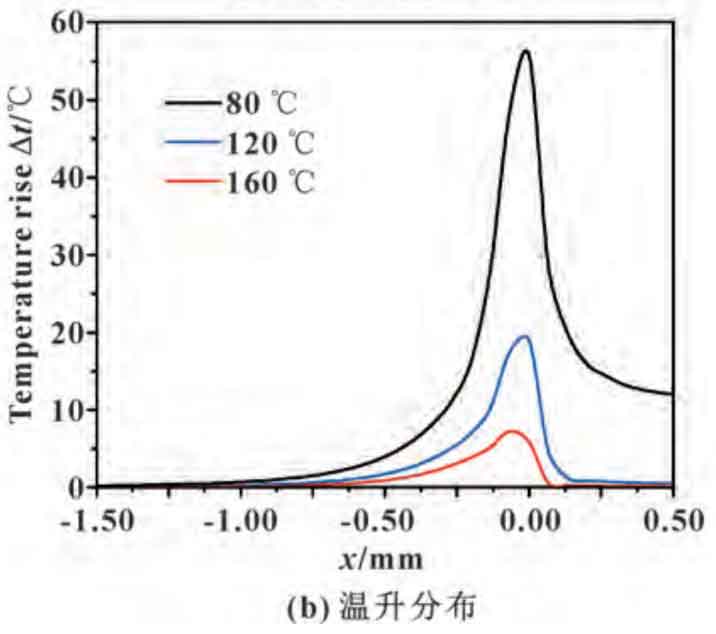

Taking the driven cone as the research object, when the working condition of 20 132 r/min and 1000 kW is fixed, the lubrication characteristics of the meshing area are studied by changing the inlet temperature to change the viscosity of the lubricating oil. The viscosity of lubricating oil corresponding to the inlet temperature of lubricating oil at 80, 100, 120, 140 and 160 ℃ is 7 108、4. 595、3. 191、2. 345、1. 789 mPa·s。 The two-dimensional profile curves of oil film pressure, oil film thickness and oil film temperature rise are shown in Figure when the inlet temperature of lubricating oil is 80, 120 and 160 ℃ respectively.

| η/( mPa·s) | hmin /μm | pmax /GPa | Δtmax /℃ | ttotal /℃ |

| 7.108 | 1.104 | 0.790 | 55.712 | 135.712 |

| 4.595 | 0.846 | 0.601 | 34.117 | 134.117 |

| 3.191 | 0.649 | 0.463 | 18.969 | 138.969 |

| 2.345 | 0.524 | 0.396 | 10.827 | 150.827 |

| 1.789 | 0.441 | 0.308 | 7.230 | 167.230 |

The changes of maximum oil film pressure, minimum oil film thickness and maximum oil film temperature rise are shown in Table 1. The total in Table 1 is the sum of the initial lubricating oil temperature and temperature rise under the current working condition. When the rotational speed and power remain unchanged, the oil film pressure, oil film thickness and oil film temperature rise will decrease with the increase of lubricating oil temperature. The decrease of lubricating oil temperature leads to the increase of lubricating oil viscosity, which enhances the bearing capacity of the oil film, and increases the pressure and thickness of the oil film. At the same time, the higher viscosity brings greater friction heat generation, which also increases the maximum temperature rise of the oil film. The higher viscosity brought by the lower lubricating oil inlet temperature makes the contact pressure rise sharply, which makes the elastic deformation of spiral bevel gear more obvious. The pressure peak does not correspond to the location of the minimum oil film thickness, but corresponds to the location of the oil film depression. This is because the location of the minimum oil film thickness is determined by the depression caused by the elastic deformation, squeezing the spiral bevel gear to the outlet locally and necking. At the same time, the lower the inlet lubricating oil temperature is, the slower the lubricating oil temperature decreases compared with the pressure.

| Mk | 7.108mPa·s | 4.595mPa·s | 3.191mPa·s | 2.345mPa·s | 1.789mPa·s |

| hmin | 0.545 | 0.640 | 0.661 | — | 0.668 |

| pmax | 0.562 | 0.655 | 0.706 | — | 0.697 |

| Δtmax | 2.041 | 2.242 | 2.084 | — | 1.401 |

| ttotal | 0.049 | 0.115 | 0.218 | — | 0.459 |

According to Table 1 and the formula, the corresponding sensitivity coefficient of each oil film characteristic parameter when the viscosity of lubricating oil changes is shown in Table 2. It can be seen that the sensitivity coefficient of the minimum thickness and maximum pressure to temperature at the design point is greater than that of the speed in Table 3, so the inlet temperature (viscosity) of lubricating oil can also be used as a key parameter to adjust the minimum film thickness and maximum pressure. The sensitivity coefficient of the maximum pressure increases first and then decreases, so changing the temperature at the oil supply temperature of 120 ℃ has the best effect on the maximum pressure. The sensitivity coefficient of the maximum temperature rise is large and fluctuates greatly. The sensitivity coefficient of the total temperature increases rapidly. The reduction of the viscosity of the lubricating oil caused by high temperature will produce large heat generation. Therefore, it is difficult to adjust the maximum temperature of the high-temperature lubricating oil by relying on the lubricating oil temperature (viscosity) to prevent coking.

| Mk | 60%No | 70%No | 80%No | 90%No | 100%No |

| hmin | 0.583 | 0.587 | 0.587 | 0.587 | — |

| pmax | 0.627 | 0.598 | 0.573 | 0.547 | — |

| Δtmax | 1.673 | 1.745 | 1.937 | 1.823 | — |