First, confirm the parameters of lubricating oil. The parameters of lubricating oil commonly used on spiral bevel gears are as follows.

| Ambient viscosity of lubricating oil (kg/m · s) | Ambient density of lubricating oil (kg/m3) | Viscosity pressure coefficient of lubricating oil (1/Pa) | Characteristic shear force of lubricating oil (Pa) |

| 0.0135 | 895 | 1.4409e^-8 | 1e7 |

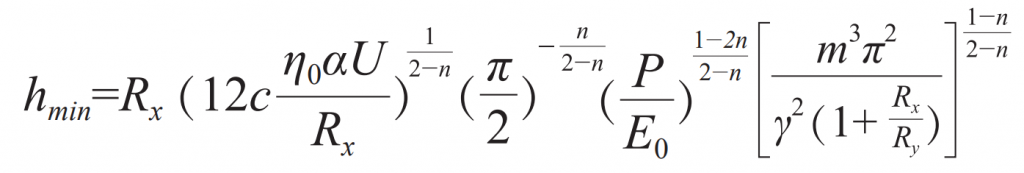

In order to describe the oil film in point contact under the condition of spiral bevel gear contact, Zheng Xuyun’s minimum film thickness equation for point contact is as follows:

Where: hmin minimum oil film thickness; η 0 Dynamic viscosity of lubricating oil at normal temperature and pressure; α Viscosity and pressure coefficient of lubricating oil; U Motion speed of contact surface; Rx equivalent radius of curvature in the direction of motion; P contact stress; Ry equivalent radius of curvature in the direction of vertical motion; E0 Equivalent elastic modulus of contact material.

| γ=b,a | c | n | m | Rx/Ry |

| 0.5 | 0.065 | 0.548 | 0.74 | 2.790 |

| 1.1 | 0.088 | 0.620 | 1 | 1 |

| 2.0 | 0.095 | 0.640 | 1.48 | 0.358 |

| 5.0 | 0.098 | 0.648 | 2.56 | 0.084 |

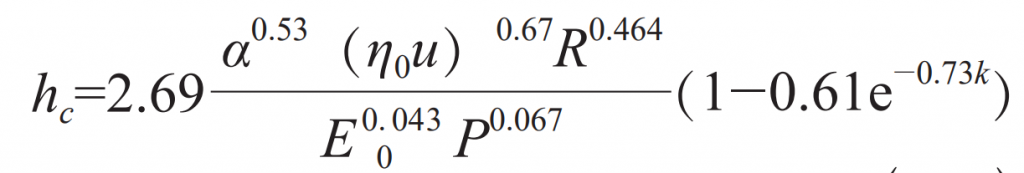

The film thickness equation of Zheng Xuyun’s point contact center is as follows:

Where: hc center oil film thickness; α Viscosity and pressure coefficient of lubricating oil; U entrainment speed of contact surface; η 0 Dynamic viscosity of lubricating oil at normal temperature and pressure; E0 Equivalent elastic modulus of contact material; R Equivalent radius of curvature of contact ball or ellipse; P contact stress; K Ellipticity, the ratio of the major axis to the minor axis of the contact ellipse.

Each parameter and operation equation are written into an operation script by using the operation software Matlab, and the numerical values and images of the two oil film thicknesses of spiral bevel gears under different meshing conditions are output respectively, so as to study the state change law of the lubricating oil film and verify the lubrication state.