As one of the key basic parts of the mechanical industry, involute cylindrical gears are widely used in aerospace, rail transit, large ships and other major national engineering fields. In recent years, the service environment of involute cylindrical gears has been deteriorating, the demand for reliability has been increasing, and the work-weight ratio index has become increasingly harsh. The bearing capacity and reliability of involute cylindrical gears have gradually emerged. Among them, the bearing capacity problem represented by contact fatigue, bending fatigue, and gluing has become the object of great concern in academic and engineering circles. A large number of researches have been carried out on the fatigue strength of involute cylindrical gears at home and abroad. The research on the anti-fatigue design and manufacture of involute cylindrical gears has been carried out extensively, and many interpretations and comparative studies have been carried out on the fatigue strength standards of involute cylindrical gears. Guo Mei and others compared the differences between ISO and HB gluing standards, but due to the small amount of data calculation, the differences and limitations between the gluing standards of involute cylindrical gears cannot be accurately obtained. However, the new generation of aviation gear transmission faces extreme service environments such as high speed, high temperature and heavy load, and the gluing strength has become one of the key bottlenecks of the reliability of aviation gear and its transmission system. It is urgent to strengthen the research on the gluing strength of involute cylindrical gears.

Although the gluing mechanism of involute cylindrical gear has not been fully revealed, it is generally believed that unlike fatigue failure, the gluing failure of involute cylindrical gear has nothing to do with the cycle life. It may occur as long as there is a short period of overload, improper lubrication or high temperature rise. The gluing of involute cylindrical gears is divided into hot gluing and cold gluing. Hot gluing is caused by local temperature rise and oil film fracture caused by friction, which leads to direct adhesion of metal on the tooth surface; Cold bonding is due to the oil film cracking caused by excessive pressure, which causes the metal on the tooth surface to adhere. Generally, cold gluing is easy to occur under the condition of low movement speed and large load.

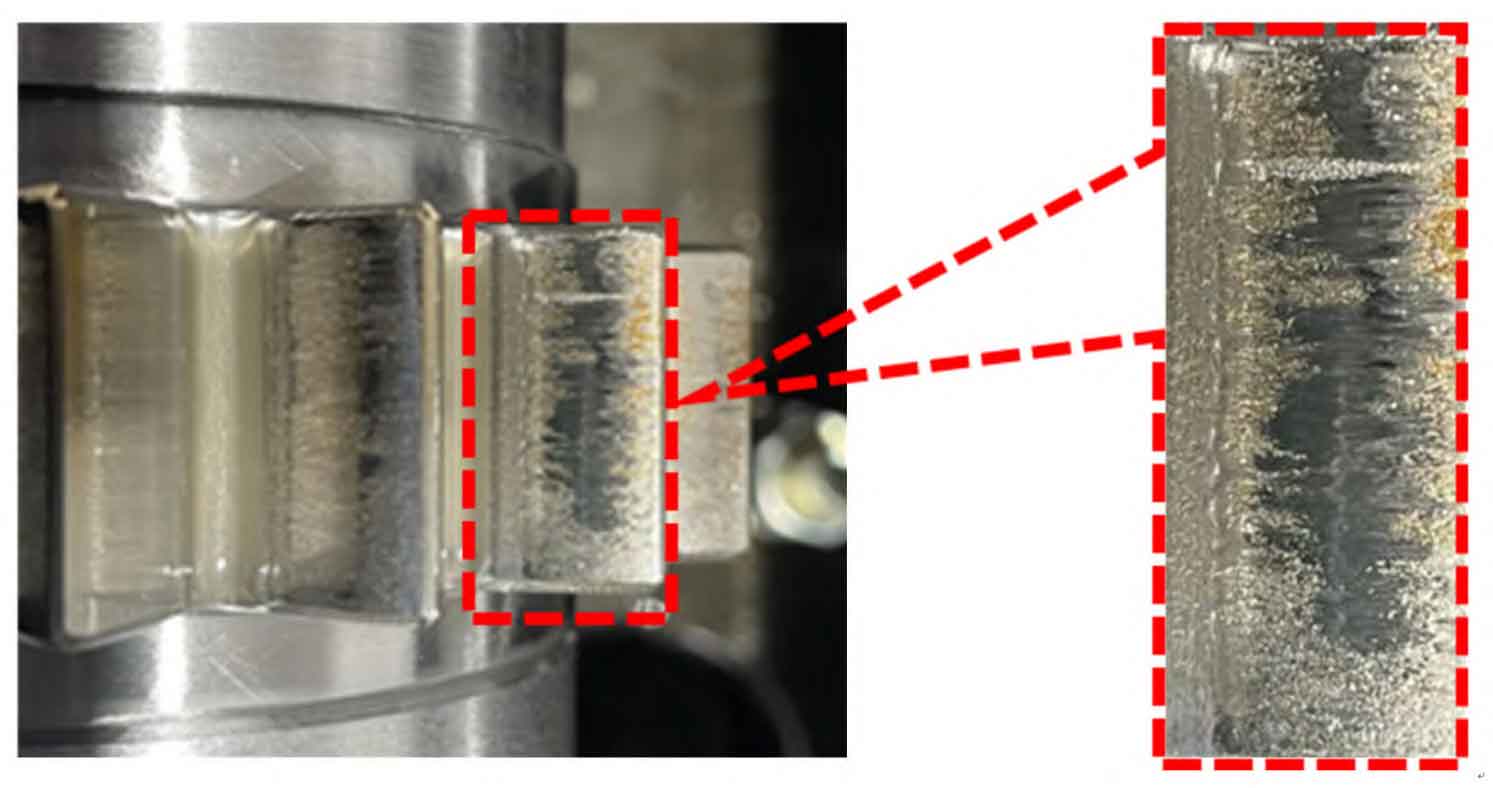

The research is about the gluing caused by the high temperature of the tooth surface, that is, hot gluing. Figure 1 shows a typical form of scuffing failure of involute cylindrical gears. During the meshing process of the involute cylindrical gear, due to the high contact pressure and relative sliding speed, the surface temperature of the involute cylindrical gear increases sharply, resulting in the instant rupture of the lubricating oil film between the meshing tooth surfaces, and then the welding between the tooth surfaces and the irregular tearing of local metal occur, resulting in the material separation of the tooth surface and permanent surface damage. Lee S C et al. carried out a series of experiments to verify the critical temperature-pressure bonding theory developed by him. According to this theory, when the contact temperature exceeds a critical value, the bonding will occur. The critical value is a function of the lubrication pressure generated by the hydrodynamic action of the elastohydrodynamic lubrication contact.

Shi XJ and others studied the effect of surface roughness on the mixed lubrication characteristics and found that due to the high friction and flash temperature at the interface of the meshing gear, scuffing failures often occur in marine transmission gears. It can be seen that the scuffing failure of involute cylindrical gears is closely related to the relative sliding speed, contact pressure and operating temperature.