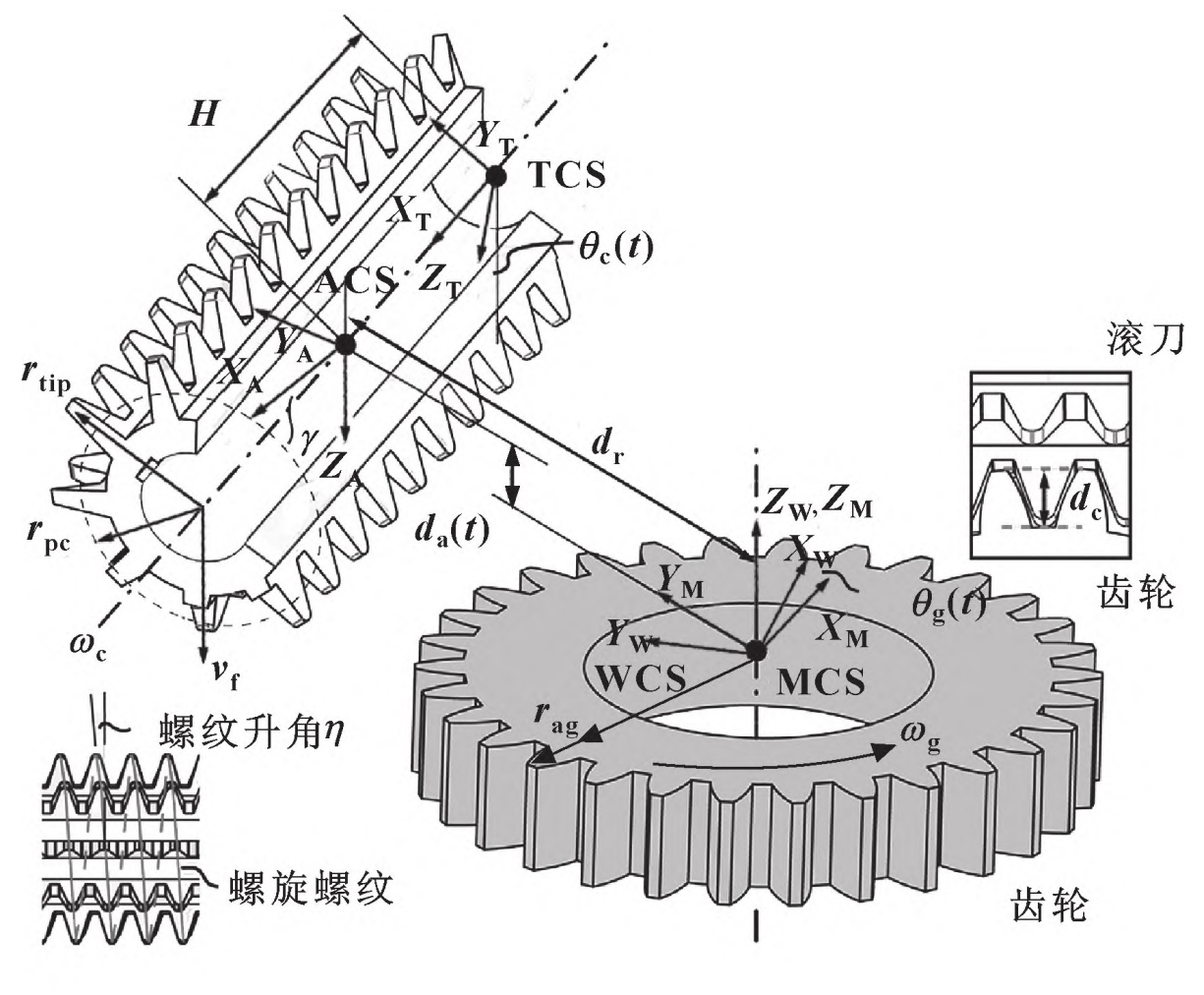

Gear hobbing is widely used in the manufacturing industry to produce high-quality straight cylindrical gears and helical cylindrical gears. Like many other machining processes, gear hobbing is also facing the challenge of increasing productivity and part quality. Through accurate process simulation, analysis and optimization, physics-based simulation can play an important role in addressing these challenges.

In conventional machining operations, such as turning, milling and drilling, the geometric analytical representation of the CutterWorkpiece Engagement (CWE) can be used to greatly simplify and speed up the calculation of digital simulation. However, in the machining of spur gear by generating method, the complexity of kinematics and part geometry makes it very difficult to derive an analytical CWE expression in advance. Therefore, in gear hobbing, some research has turned to rely on solid modeling technology to solve CWE. However, due to the need to construct and update a large number of 3D analytical geometric entities to track each section feature, the calculation has become increasingly time-consuming. LOTFI et al. proposed to use a series of parallel planes intersecting with the tool rake surface to represent the workpiece geometry, thus completing the CWE calculation and cutting force prediction. However, when the cutting conditions change, the prediction error fluctuation range is relatively large.

Recent research shows that the three-dimensional Dexel discrete geometry technology can achieve a good balance between the calculation speed and the prediction accuracy during the NC machining simulation operation. For example, Li Yipeng and others used the three-way Dexel model to represent the workpiece and tool, and obtained a faster simulation speed than the one-way Dexel model, while maintaining a higher numerical control simulation accuracy. Therefore, a gear hobbing simulation method based on three-dimensional Dexel model is developed. Different from the simulation method that only calculates CWE, the proposed simulation method can extract the geometric characteristics of the workpiece in the whole process, thus can simulate and measure the machining error caused by residual stress and elastic deformation in the virtual environment, and when the cutting conditions of spur gear change, the proposed simulation method can still successfully predict the cutting forces in multiple directions.