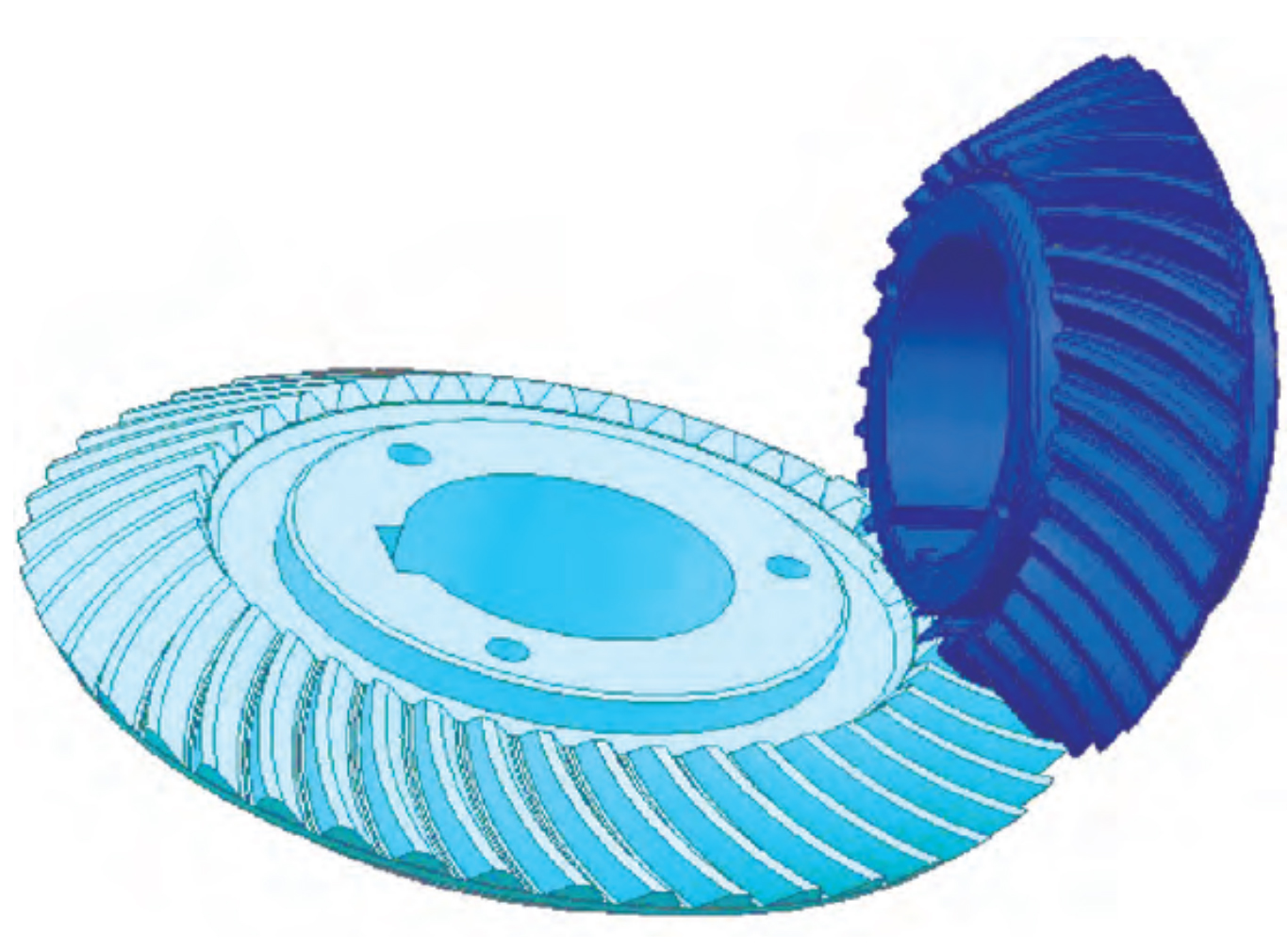

Spiral bevel gears have the advantages of smooth transmission, large load capacity, low noise, and are widely used in aviation, aerospace and engineering machinery transmission systems. The grinding head is the core component of the grinding machine. It can not only bear the vibration generated by the internal gear and gear box excitation force, but also bear the vibration generated by the impact force of the steel billet when working.

The grinding head of the grinding machine is driven by spiral bevel gear. The gear pair not only produces complex contact stress, but also produces mechanical vibration under the action of excitation force. When the frequency of the excitation force approaches the natural frequency of the gear pair, resonance will occur, resulting in serious noise, and even the gear pair will fail completely. Modal analysis is the basis and prerequisite for analyzing the more complex dynamic characteristics of the system. In order to obtain the dynamic performance results of the system more accurately, the modal distribution results that are consistent with the actual situation of the system must be obtained first. Therefore, it is of great significance to analyze the natural vibration characteristics of spiral bevel gears, find out their weak links under working conditions, and improve the structural design to avoid resonance. This will improve the fatigue strength and life of spiral bevel gears, which has important practical application value.

In recent years, gear is the core part of the transmission system. Chinese and foreign scholars have carried out theoretical and experimental research on the contact, stiffness and dynamics of gear meshing in different applications. Based on the vector form intrinsic finite element method, Hou et al. deduced the calculation formula of 8-node hexahedral element and applied it to the contact analysis of gears. This method can accurately analyze the gear meshing problem under the rough meshing model, but the mechanical accuracy of the gear for precise transmission has yet to be verified, and this method is not universal. Liu Mingyong and others used finite element software to study the distribution of contact force on the tooth surface of helical gears in the process of meshing, taking into account the influence of plastic deformation, tooth surface friction, temperature and material linear strengthening. Yang Expo and others used the finite element method to analyze the contact stress and load transmission error of gear pairs with different geometric transmission errors, and obtained that the edge contact degree decreased with the increase of transmission error under specific working conditions. Ji Hong and others have provided effective solutions for the design and processing of spiral bevel gears with complex speed ratios by analyzing the contact of the tooth surface of spiral bevel gears, using the method of gear grinding to process gears, and using the three-coordinate tooth measurement to process and detect spiral bevel gears. Ren Haiguo and others calculated the natural vibration characteristics of five spiral bevel gears under different web thickness, and summarized several basic low-order modes. Faydor et al. gave the finite element contact analysis method of three-tooth spiral bevel gear. In order to verify the reliability of the helical gear structure of the high-pressure pump, Liu Kun and others carried out a static analysis of the stress at the gear tooth mesh, and carried out a modal analysis to avoid the occurrence of resonance. The vibration characteristics and natural frequencies of the system were obtained through analysis, which verified the rationality of the structure. Li Fei and others analyzed the influence of friction coefficient and coincidence degree on the vibration amplitude of transmission system. It is obtained that the friction coefficient is different under different working conditions, and there is a certain rule with the change of lubricating oil. Li Yuan and others used finite element software to analyze the meshing process of aviation spiral bevel gears. Luan Xiaochi et al., aiming at the fracture failure of driven wheel caused by traveling wave resonance in the use of a certain type of aero-engine transmission bevel gear, used the method of combining simulation analysis and experimental verification to study the traveling wave resonance characteristics and its influence law of spiral bevel gear under the condition of parameter adjustment. Li Shengpeng et al. analyzed the dynamic frequency of bevel gear by using ansys software considering the prestress caused by rotational speed and transmission torque, and concluded that centrifugal force and meshing torque have certain influence on the vibration frequency of spiral bevel gear.

To sum up, scholars have done a lot of research on the natural frequency and vibration mode of gears through experiments, theoretical analysis or finite element method. However, there are few studies on dynamic contact modal analysis under actual working conditions. Therefore, a set of grinding head gear reducer is designed according to the needs of a grinding machine in an iron and steel company, which is driven by spiral bevel gear. In order to ensure the consistency between the modal data and the actual working condition, an accurate model of the grinding head transmission system of the grinding machine should be established, and the constraint factors should be applied to the bevel gear as the actual condition. During the modal calculation, the contact modal analysis will add the boundary conditions to the object, so that the analysis will be closer to the actual situation of the project. The finite element analysis software is used to study the natural characteristics and vibration modes of spiral bevel gears with and without contact under steady-state conditions, providing a reliable theoretical basis for the fatigue life and design of spiral bevel gears.