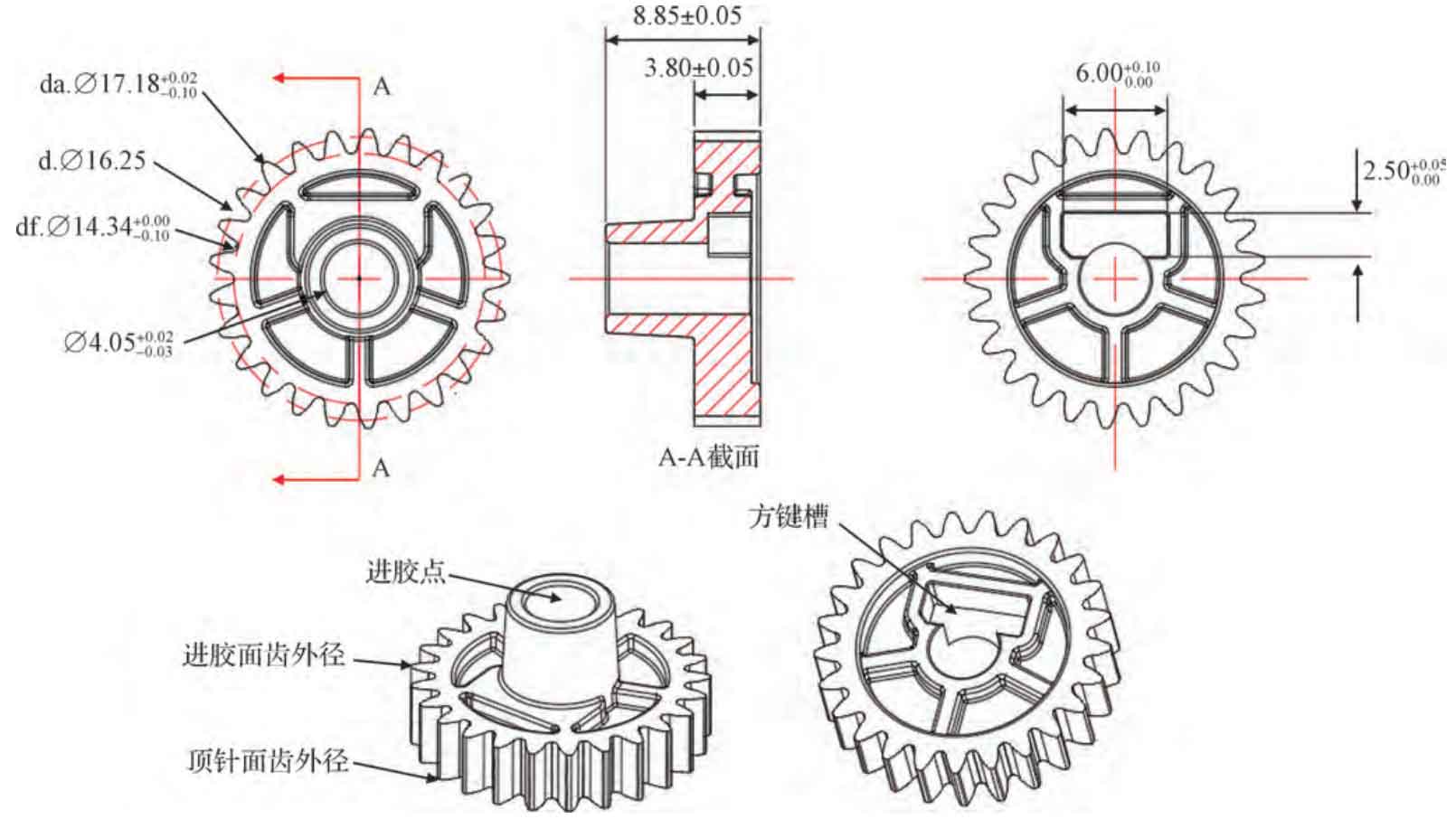

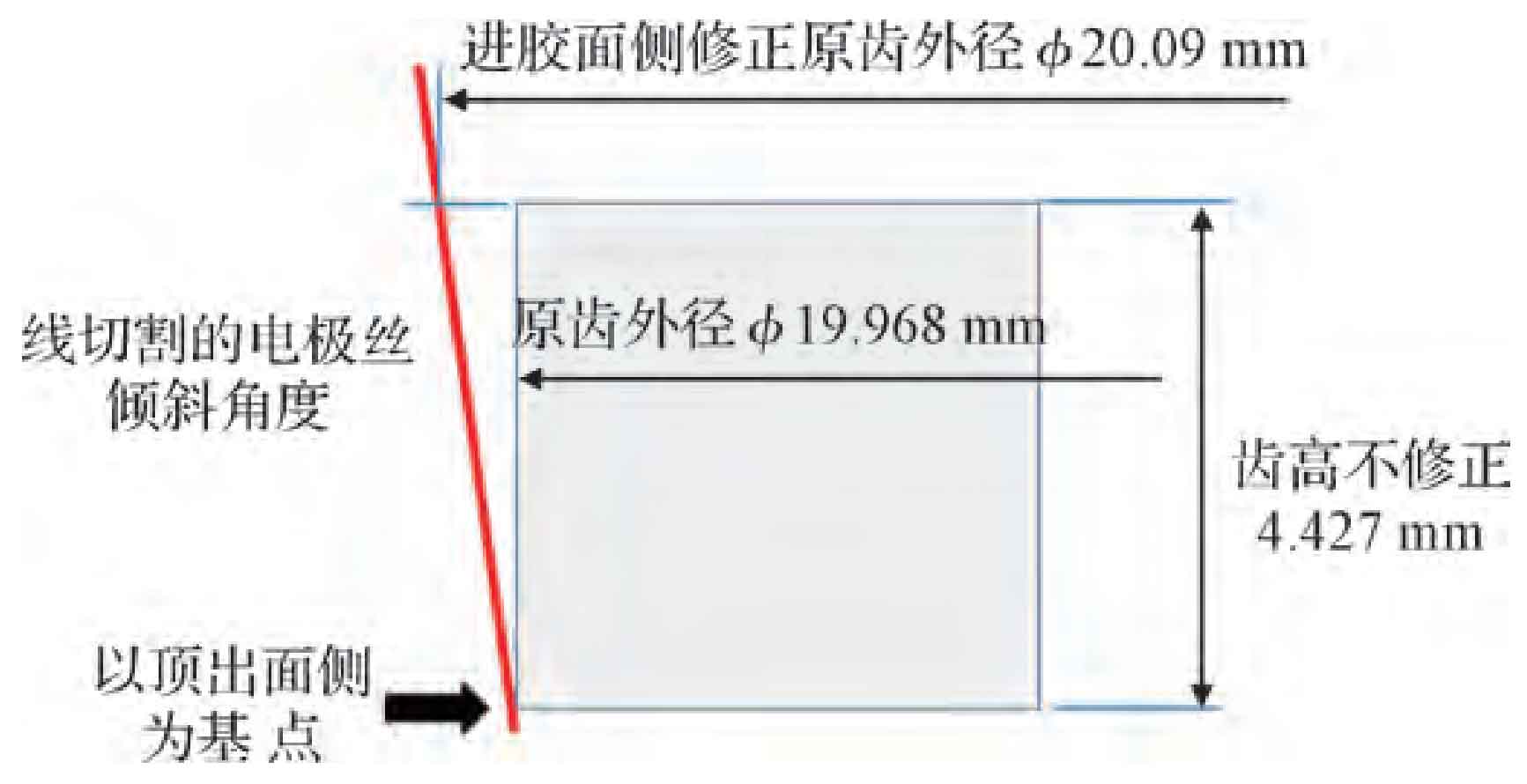

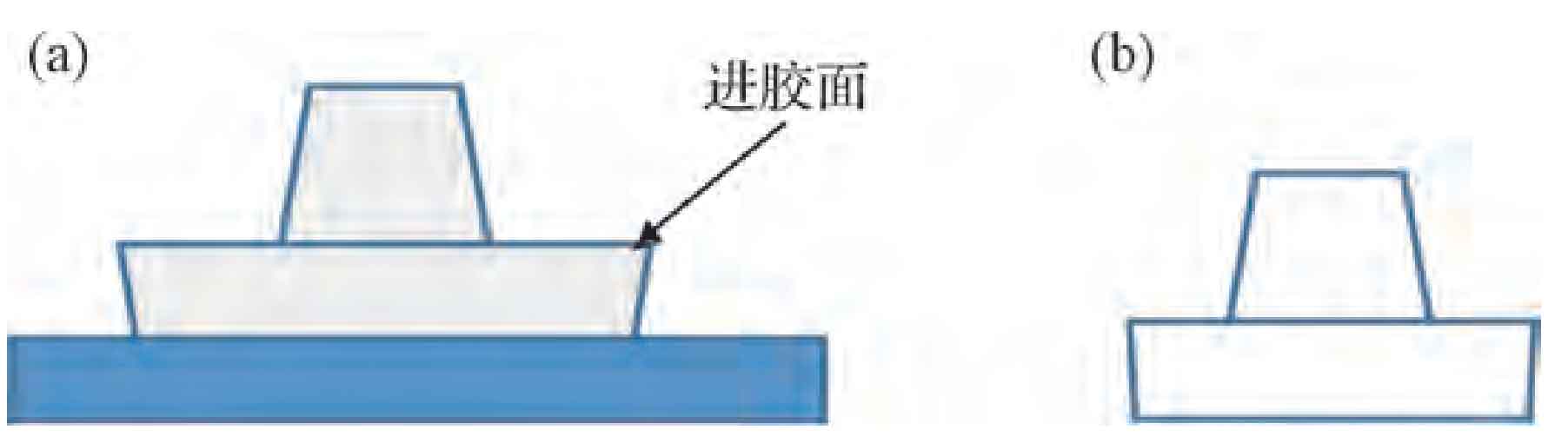

After the above deformation phenomenon is found, the method of linear cutting the inclined plane of spur gear at the corresponding position is adopted to compensate the size, as shown in Figure 1, that is, the tooth-shaped mold core with large size on the side of the glue feeding surface and small size on the ejecting surface is made, and the schematic diagram is shown in Figure 2 (a).

Referring to the original design in Figure 3, the waist shrinkage of the traditional injection spur gear was not observed in the spur gear prepared after the compensation measures were taken, which indicates that the thinned design of equal flesh thickness can effectively maintain the correct tooth shape of the injection plastic spur gear. However, in the design of the MIM spur gear products, it is necessary to consider that the powder particle size and geometric shape will cause distortion such as large and small tooth diameter.

The shrinkage ratio of the MIM process is also not absolutely uniform, and the shrinkage of the Z axis (gravity traction of the earth) is relatively stable. However, due to the influence of friction and product quality in the X and Y directions, as well as the factors of spur gear structure, some dimensional shrinkage ratios must be adjusted by modifying the mold. Under the known rule conditions, the adjustment (powder particle size is less than 40 μ M, D50 is close to 10 μ M, the surface morphology of equiaxed powder is smooth, etc.), which can make the size shrinkage conform to linear proportional relationship.