This paper expounds the tooth turning principle of spiral tooth surface gear, deduces the tooth surface equation of spiral tooth surface gear, compares and analyzes the tooth surface error and tooth profile error of the tooth surface and theoretical tooth surface of spiral tooth surface gear, and obtains the following conclusions.

(1) Aiming at the problem that the existing gear generation processing method can not solve the problem of spiral tooth surface gear processing, a two-degree-of-freedom gear turning processing method for spiral tooth surface gear is proposed. The theoretical model of helical gear tooth turning is established, the meshing and generating motion of two degrees of freedom in the process of turning is deduced, and the mathematical model of helical gear tooth turning is constructed.

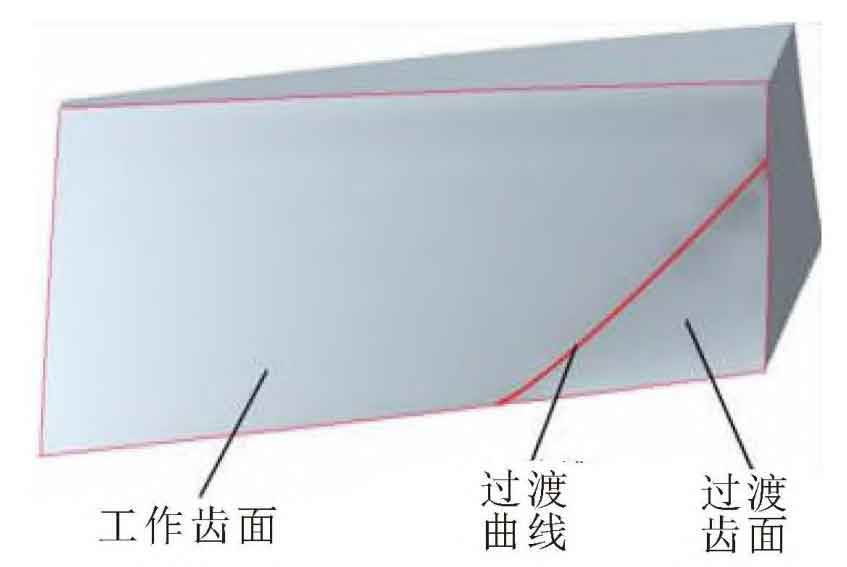

(2) The tooth surface and theoretical tooth surface of helical gear are compared from the two angles of tooth surface error and tooth shape error. The error of working tooth surface obtained is very small, but the error of concave transition surface is large, which shows the feasibility of tooth turning of helical gear.

(3) The work done in this paper is only the theoretical stage of the research on the tooth turning method of the helical gear. The optimization of the cutting edge structure and the tooth turning process test of the helical gear will be carried out in the follow-up research.