Since the rigid body shell of the inner ring of the spur gear driving wheel is fully constrained, the theoretical rotation angle of the driving wheel is θ 1b is 0 °, but due to the elastic deformation of the gear teeth, the actual rotation angle of the spur gear driving wheel is caused θ 1a is not 0 °. According to the transmission ratio relationship, the actual rotation angle of the driving wheel θ 1a and the actual rotation angle of the driven wheel θ The following relationship exists between 2a:

In the formula, Z2 represents the number of driven gear teeth; Z1 represents the number of driving gear teeth.

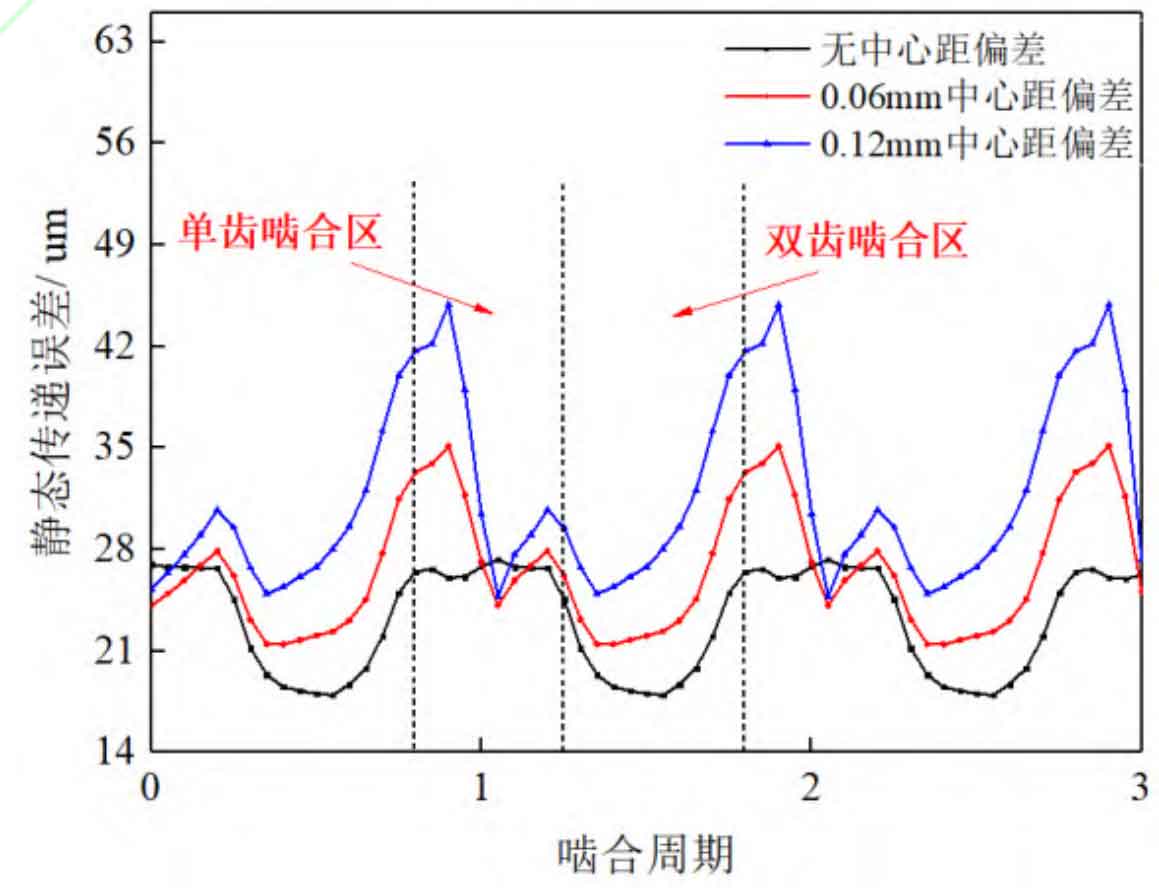

Extract the actual rotation angle of the rigid body shell of the spur gear driven wheel with different center distance deviations and different meshing points θ 2a. Calculate and plot the static transfer error curve using the formula, as shown in Figure 1.

According to the static transmission error curve, the magnitude and fluctuation of the static transmission error of the entire spur gear pair will increase with the increase of the center distance deviation.

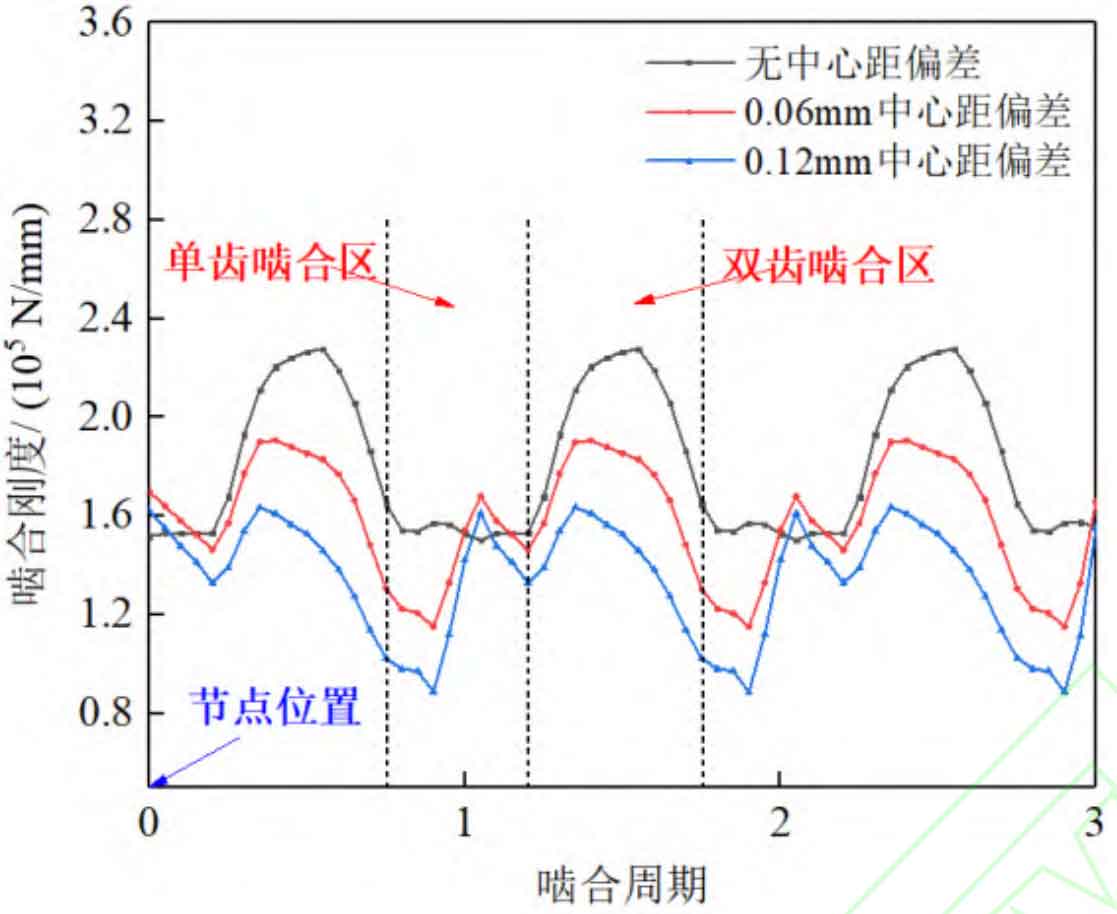

Extract the actual rotation angle of the rigid body shell of the driven wheel θ 2a Bring in the formula, calculate and draw the meshing stiffness curve of the spur gear pair, as shown in Figure 2.

Through calculation, when the center distance deviation is 0 mm, 0.06 mm, and 0.12 mm, the meshing stiffness RMS values of the single tooth meshing area are 154886 N/mm, 141105 N/mm, and 154886 N/mm, respectively, and the meshing stiffness RMS values of the double tooth meshing area are 201578 N/mm, 171055 N/mm, and 141733 N/mm, respectively. Based on the meshing stiffness curve, it can be seen that the overall meshing stiffness of spur gear pairs decreases with the increase of center distance error. The meshing stiffness of the double tooth meshing area is more sensitive to the change of center distance deviation. For each 0.06 mm increase in center distance deviation, the stiffness of the single tooth meshing area decreases by approximately 9%, and the stiffness of the double tooth meshing area decreases by 15%. In addition, due to the influence of center distance deviation, the meshing point deviates from the theoretical meshing position of the original spur gear pair, resulting in a sharp increase in the meshing stiffness of the single tooth meshing region at a certain point.