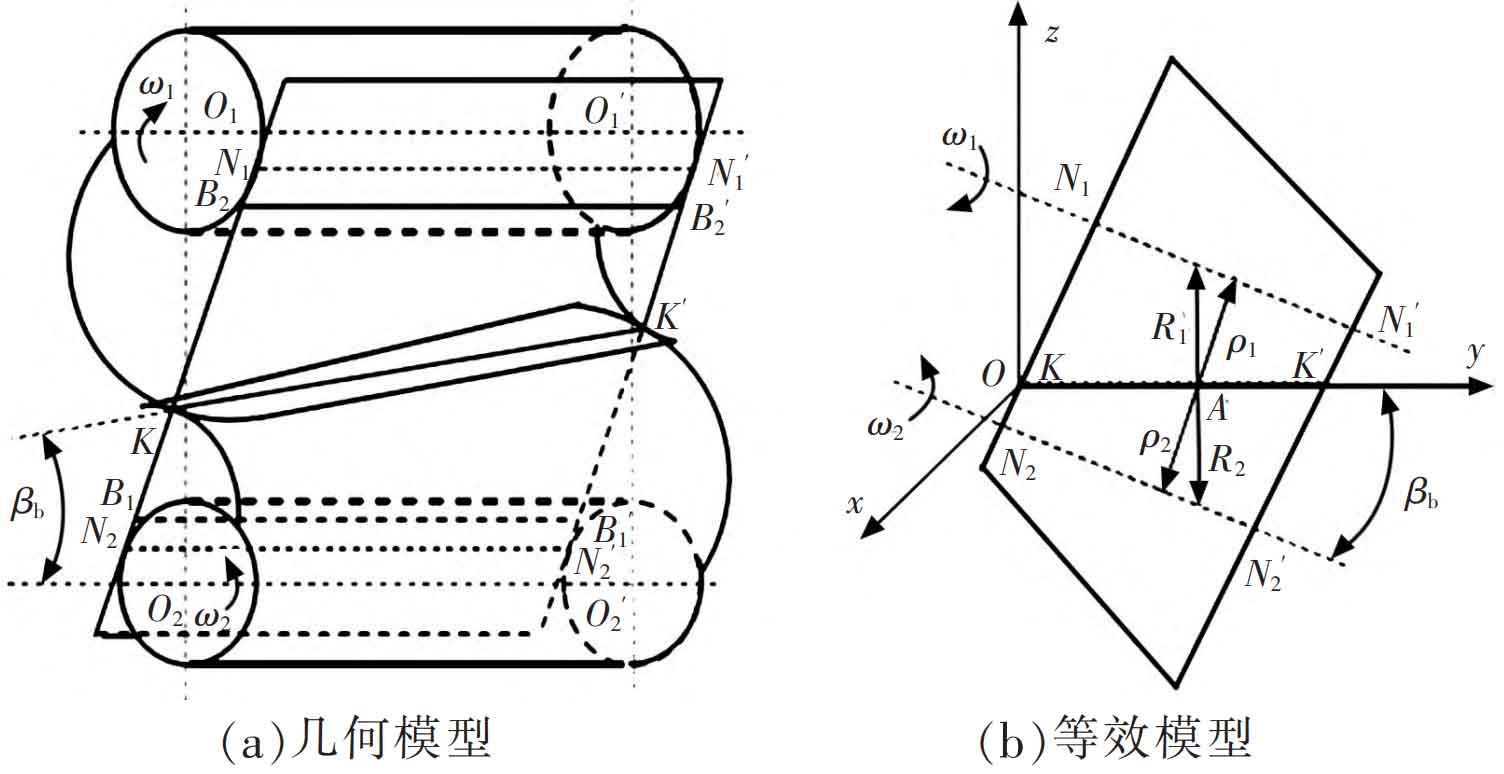

Helical gear transmission is usually equivalent to a pair of reverse tapered roller contacts for processing, and then segmented along its contact line direction. Each small segment can be considered as a pair of spur gear pair contacts, as shown in the figure.

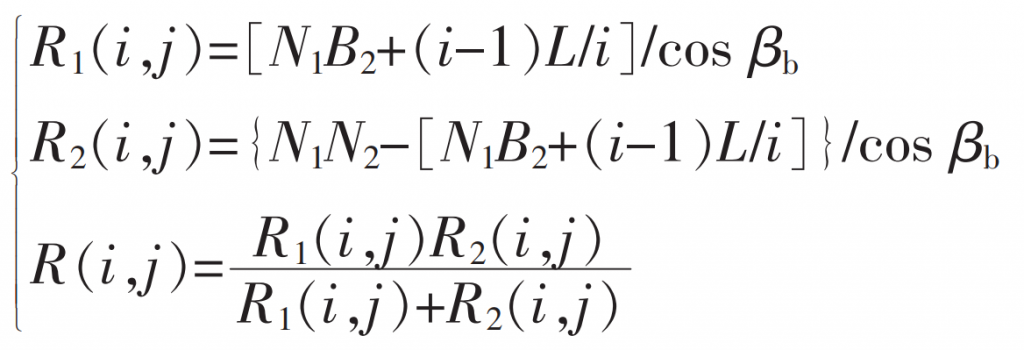

The radius of curvature R1 of the driving wheel, the radius of curvature R2 of the driven wheel, and the comprehensive radius of curvature R of any meshing position A (i, j) on the contact line can be expressed as follows:

In the formula, N1N2 – theoretical meshing line length.

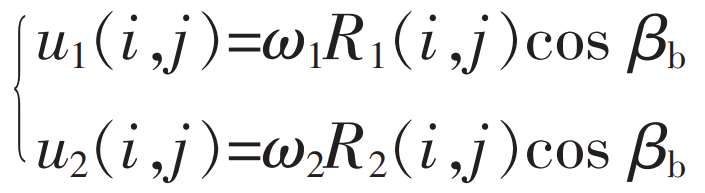

The tangential speed of the helical gear at the meshing position A can be expressed as:

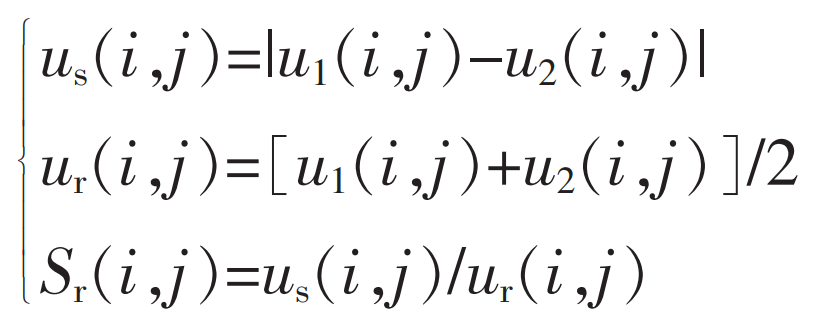

The relative sliding speed us, entrainment speed ur, and sliding roll ratio Sr at position A can be expressed as:

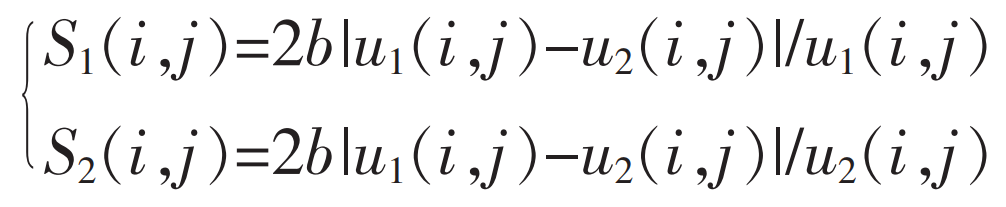

According to the calculation method of point-to-point slip distance, the slip distance of a meshing point on the tooth profile of the helical gear driving wheel and the driven gear is expressed as follows:

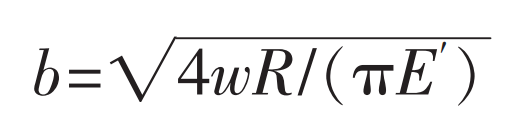

The contact half width of the meshing point of the helical gear in the sliding direction:

Where: E ‘- comprehensive radius of curvature.