Based on the simulation results of Adams, experimental testing and analysis were conducted on the speed fluctuation characteristics of elliptical arc tooth line cylindrical gear transmission to verify the variation law of factors affecting the speed fluctuation characteristics of elliptical arc tooth line cylindrical gear transmission; Conduct prototype speed fluctuation testing experiments to understand the law of speed fluctuation; At the same time, compare experimental data with simulation data to summarize the speed fluctuation pattern. From the three influencing factors, the factor that has the greatest impact on speed fluctuations is speed. Therefore, experimental testing and analysis will be conducted on the rotational speed next.

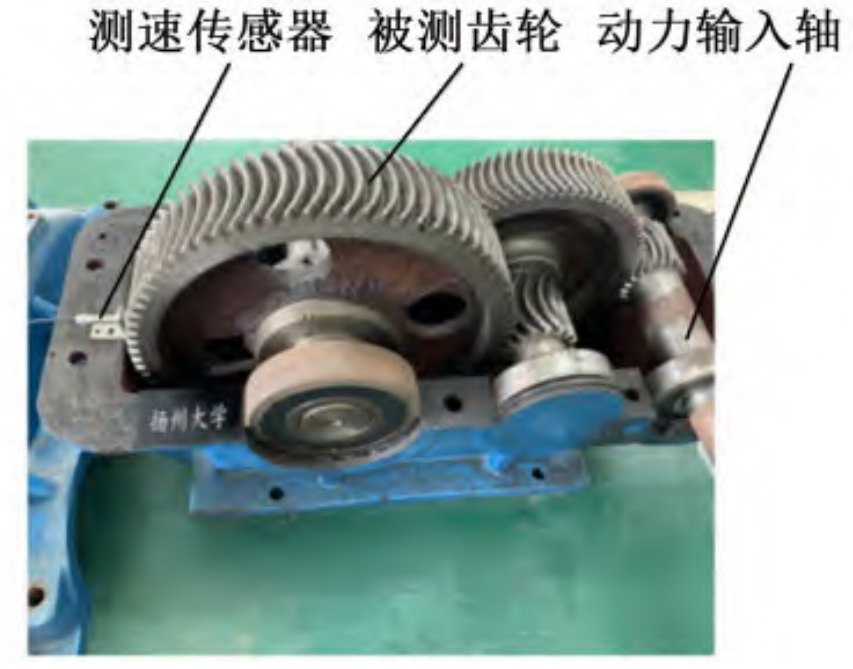

The gear processing is carried out using a special machine tool for elliptical arc tooth line cylindrical gears, and some gear samples processed are shown in Figure 1.

Select one pair of gear pairs for the speed fluctuation experiment of elliptical arc tooth line cylindrical gears, and accurately assemble the gears on the workbench according to the standard state. The small gear is the driving wheel, and the standard large gear is the driven wheel. The gear meshing experimental device built is shown in Figure 2. The experiment uses a three-phase asynchronous motor Y132S-4 to drive the gear to rotate through a triangular belt, and the experiment uses a Hall gear speed sensor for data collection.

The speed measurement of experimental data adopts PLC as the technical principle to measure the frequency of pulse reception.

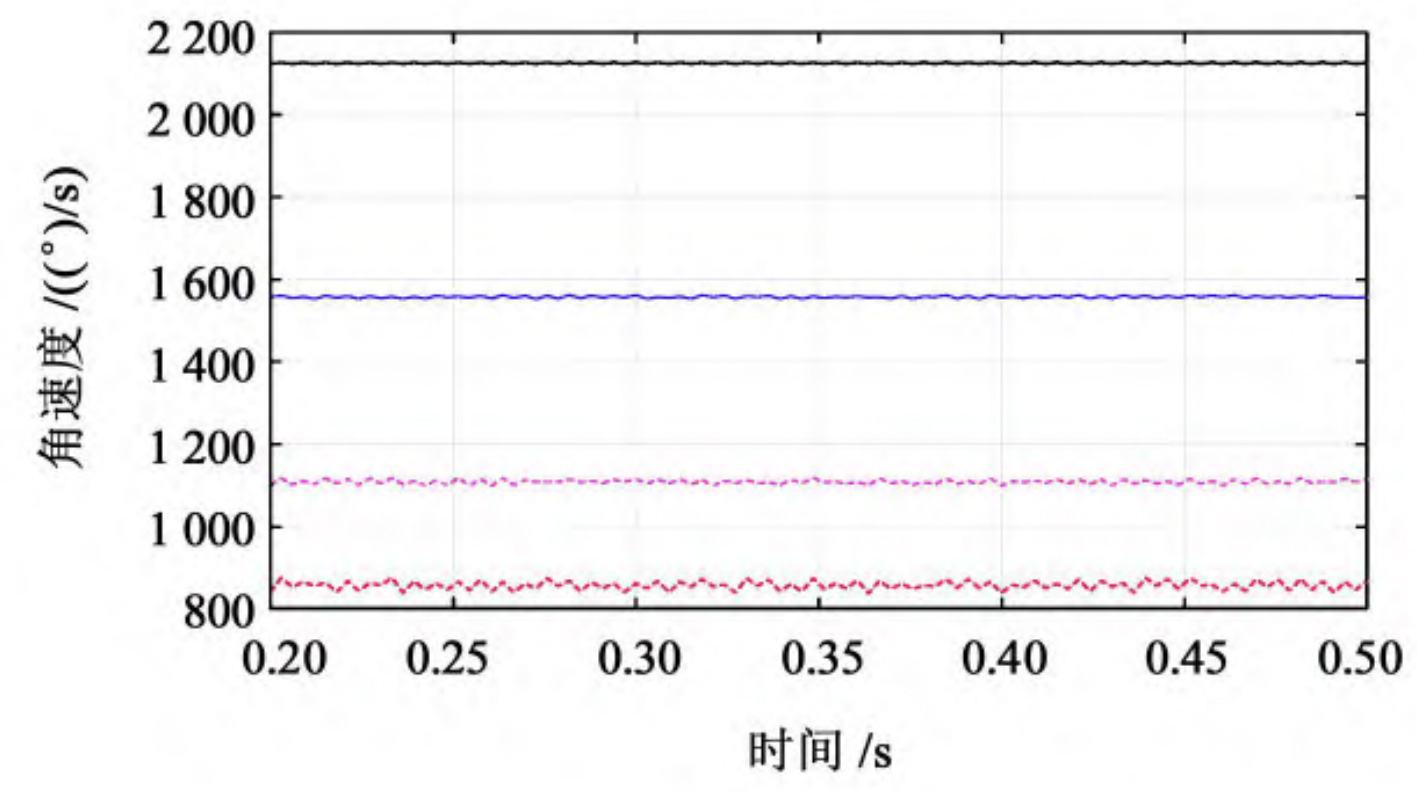

Set the output shaft speeds to n=857 (°)/s, n=1106 (°)/s, n=1556 (°)/s, and n=2123 (°)/s. Collect the rotational speed values under four different scenarios through the data collection window, and import the collected data into Matlab. The results are shown in Figure 3.

Figure 3 shows the state diagram of the actual speed and time of the measured elliptical arc tooth line cylindrical gear at an output shaft speed of n=857 (°)/s, n=1106 (°)/s, n=1556 (°)/s, and n=2123 (°)/s. Based on the above experimental data, obtain the maximum, minimum, and average values of the curve, and calculate the theoretical speed of each driven gear based on the transmission ratio, as shown in the table.

| Theoretical speed/(°)/s) | Maximum value of driven wheel speed/(°)/s) | Minimum value of driven wheel speed/(°)/s) | Average value of driven wheel speed/(°)/s) | Speed fluctuation coefficient δ |

| 857 | 859.758 | 853.159 | 856.245 | 0.007 707 |

| 1 106 | 1 110. 971 | 1 104. 795 | 1 105. 462 | 0.005 587 |

| 1 556 | 1 559. 378 | 1 553. 502 | 1 556. 002 | 0.003 776 |

| 2 123 | 2 127. 468 | 2 120. 500 | 2 122. 997 | 0.003 282 |

From the table, it can be seen that the fluctuation coefficient of speed decreases with the increase of the driving wheel speed, that is, as the speed increases, the fluctuation coefficient of speed gradually decreases, and the smoothness of elliptical arc tooth line cylindrical gear transmission becomes better and better. The experimental data is consistent with the final simulation results, verifying the variation pattern of factors affecting the speed fluctuation characteristics of elliptical arc tooth line cylindrical gear transmission.