1. Simulation working condition parameters

Select a certain mining spur gear pair for simulation calculation, and the parameters of the spur gear and operating conditions are shown in Table 1. Due to the harsh working environment, high power transmission, and severe impact vibration of mining spur gears, the operating condition coefficient KA=2 is taken 25。

| Parameter | Pinion | Wheel |

| Number of teeth | 25 | 80 |

| Modulus/mm | 8 | 8 |

| Pressure angle (/°) | 20 | 20 |

| Tooth width/mm | 200 | 200 |

| Materials, heat treatment | 20CrNiMo carburizing and quenching | 15CrNi6 carburizing and quenching |

| Tooth surface roughness/µm | 0.2 | 0.2 |

| Lubricant viscosity (/Pa · s) | 0.038 | 0.038 |

| Viscous pressure coefficient of lubricating oil/Pa^-1 | 2.2X10^-8 | 2.2X10^-8 |

| Speed (/r/min) | 1 500 | 468.75 |

| Input power/kW | 800 | 800 |

2. Calculation of contact stiffness of spur gears and stiffness of spur gear elastohydrodynamic friction pairs

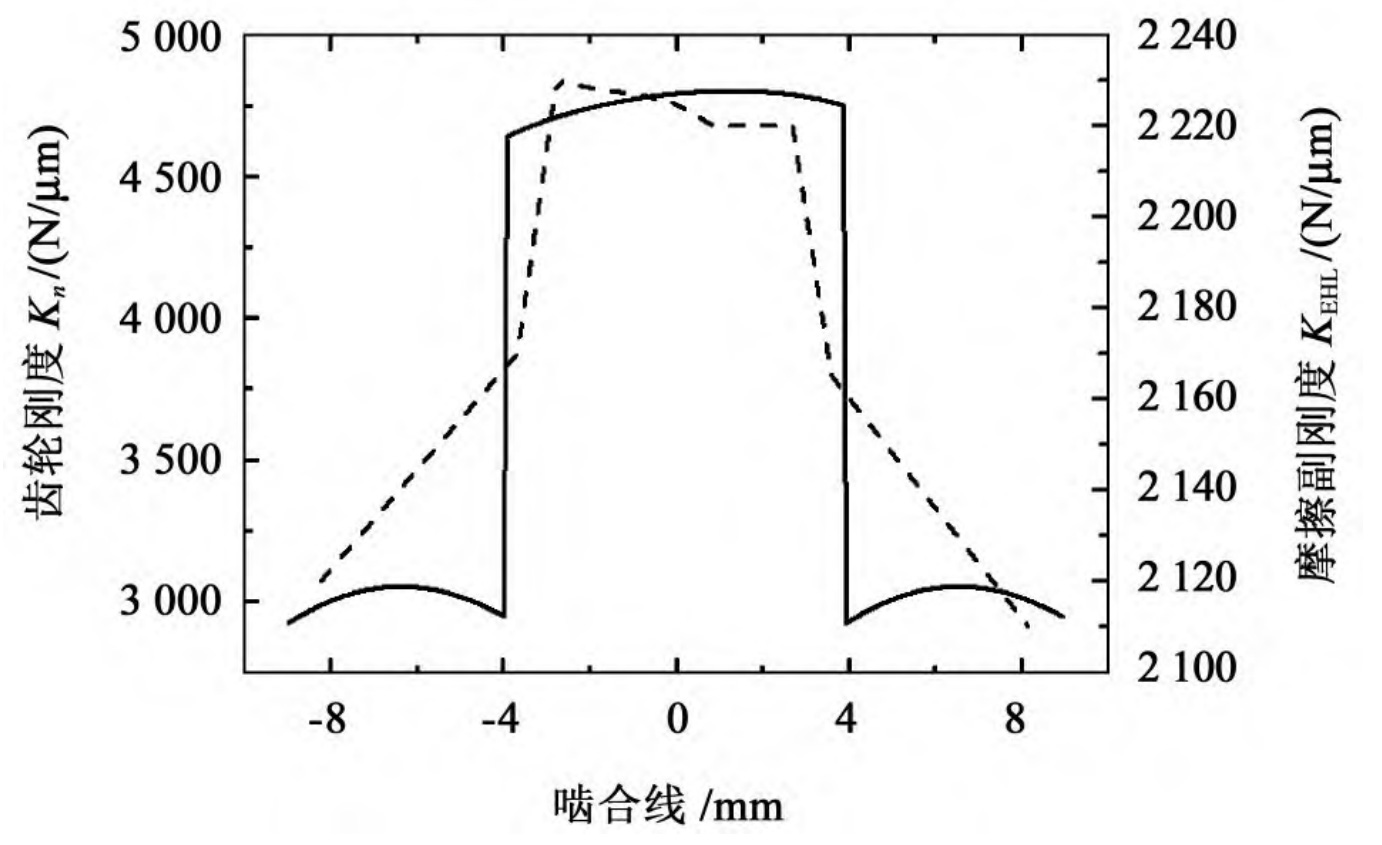

According to the parameters of the spur gear in Table 1, the stiffness of each meshing point corresponding to a pair of gear teeth within one meshing cycle and the stiffness of the tooth surface elastohydrodynamic friction pair are calculated using the Ishikawa formula, as shown in the figure.

3. Calculation of the meshing stiffness of spur gears and the meshing stiffness of spur gear elastohydrodynamic friction pairs

According to the figure, obtain the meshing stiffness C of the spur gear using the formula γ= 19. 35 N/(mm · µ m), meshing stiffness of spur gear elastohydrodynamic friction pair CEHL=12 32 N/(mm·µm)。

By C γ Calculate the maximum modification amount and length of gears based on the ISO method using the formula and the value of CEHL, and calculate the maximum modification amount and length of spur gears based on the stiffness of the elastohydrodynamic friction pair using the formula. The results are shown in Table 2.

| Shaping method | Maximum shaping amount/µ m | Trimming length/mm |

| ISO shaping | 21.13 | 8.5 |

| EHL shaping | 33.18 | 8,5 |

From Table 2, it can be seen that after considering the effect of elastohydrodynamic lubrication on meshing stiffness, the maximum modification amount is increased from 21 13 µ m increased to 33 18 µ m, an increase of 57%, indicating a significant impact of elastohydrodynamic lubrication on the modification amount of spur gears.