In order to explore the strengthening mechanism of coatings, the tooth shape and orientation parameters of helical gears with/without coatings were obtained through the FCL Å 250H helical gear precision testing bench, and they were substituted into the finite element model for simulation analysis.

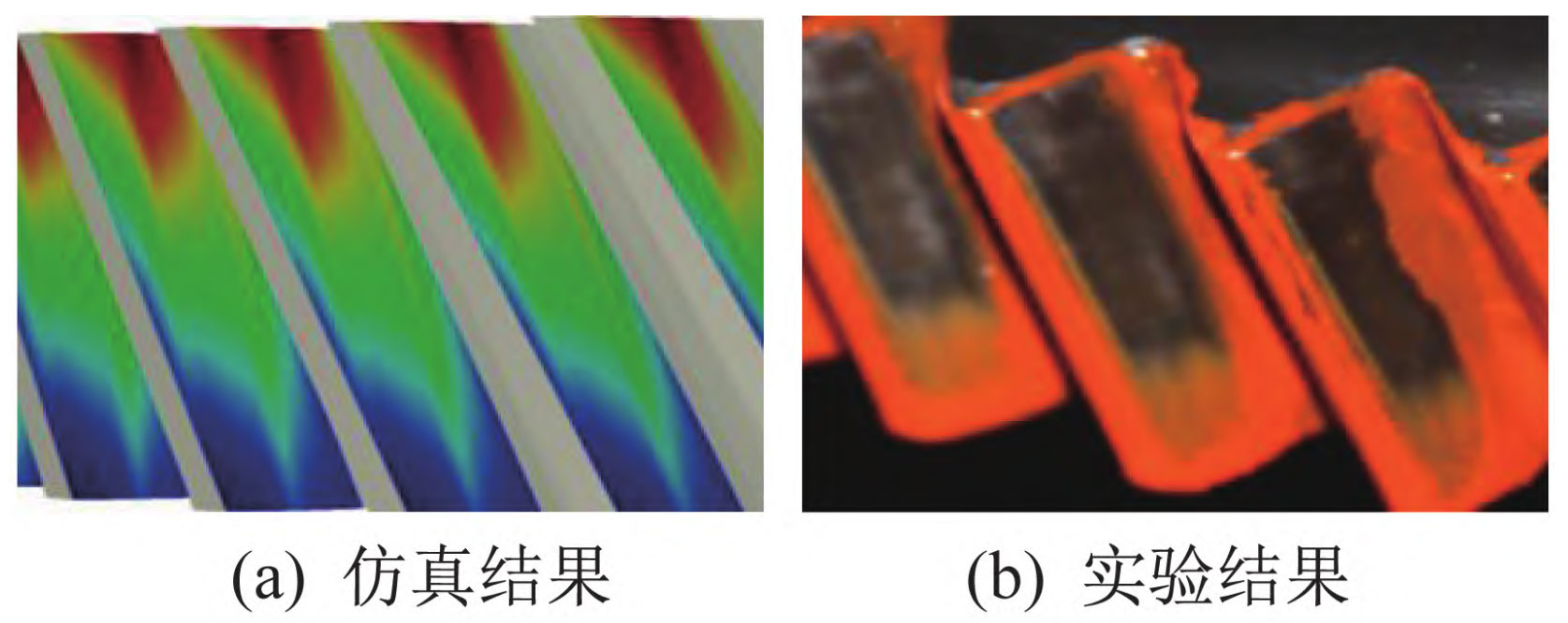

Firstly, experimental verification is conducted on the accuracy of the helical gearbox model. Apply red lead powder on the surface of the gear teeth and conduct contact experiments on helical gear pairs. Set the input speed to 100 r/min and the input torque to 50 N · m to obtain the contact marks between the box and the helical gear. The contact marks obtained from experiments and simulations are shown in Figure 1. As shown in the figure, the simulation results are in good agreement with the experimental results, verifying the accuracy of the constructed finite element model.

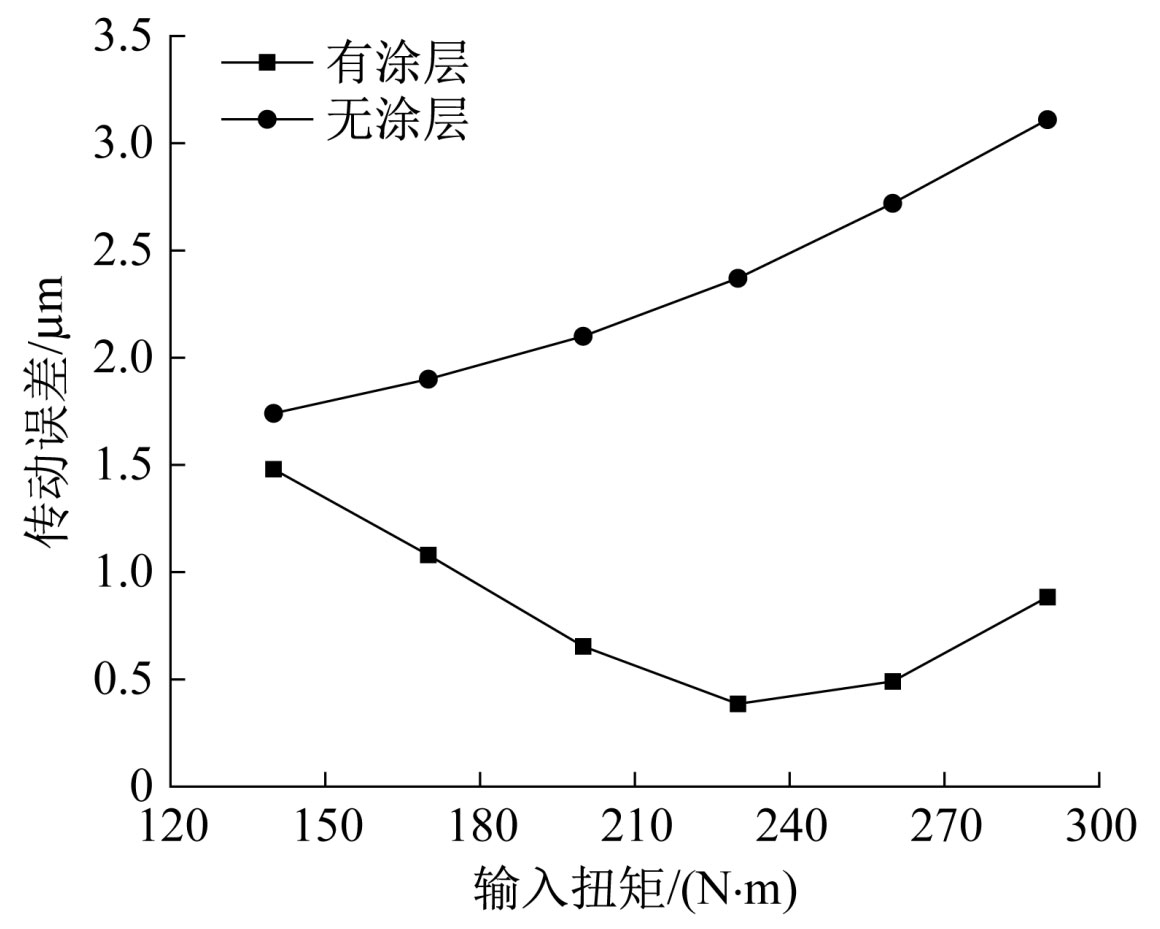

Finite element analysis was conducted on the transmission error of helical gear pairs with/without coating under different input torques, and the results are shown in Figure 2. From the figure, it can be seen that the transmission error of coated helical gears is significantly smaller than that of uncoated helical gears, indicating that coated helical gears are less impacted during the meshing process and the transmission is more stable; The transmission error of coated helical gears shows a trend of first decreasing and then increasing, with the smallest transmission error at an input torque of 230 N · m, while the transmission error of uncoated helical gears increases with the increase of input torque. Therefore, the coating after running in can maximize the compensation for errors caused by meshing impact, reduce tooth surface wear, make the transmission more stable, and improve the fatigue life of helical gears.

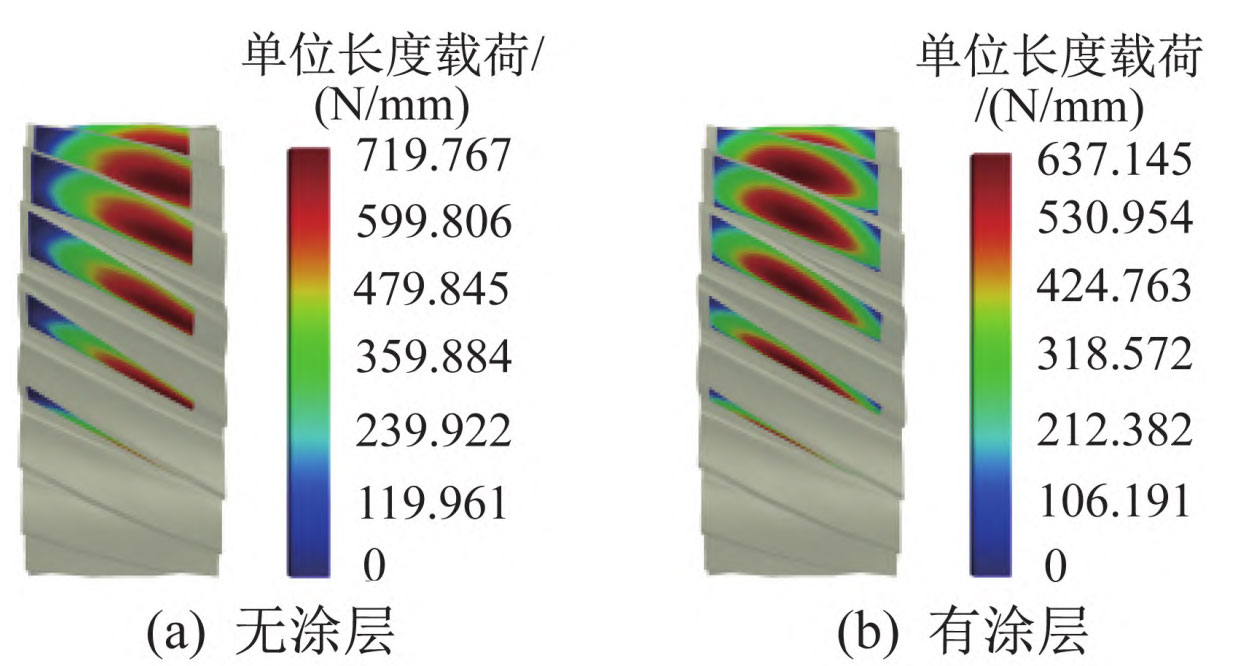

The cloud diagram of tooth surface load distribution under the working condition of 2500 r/min and 230 N · m is shown in Figure 3. From the figure, it can be seen that after running in, the stress concentration distribution area on the tooth surface of the coated helical gear shifts from the edge of the meshing tooth surface to the center of the tooth surface, and the load per unit length is significantly reduced, and the load deviation situation is significantly improved. It can be seen that in the initial running in stage, the coating has a positive effect on reducing vibration and noise in helical gear transmission and alleviating the effect of eccentric load.