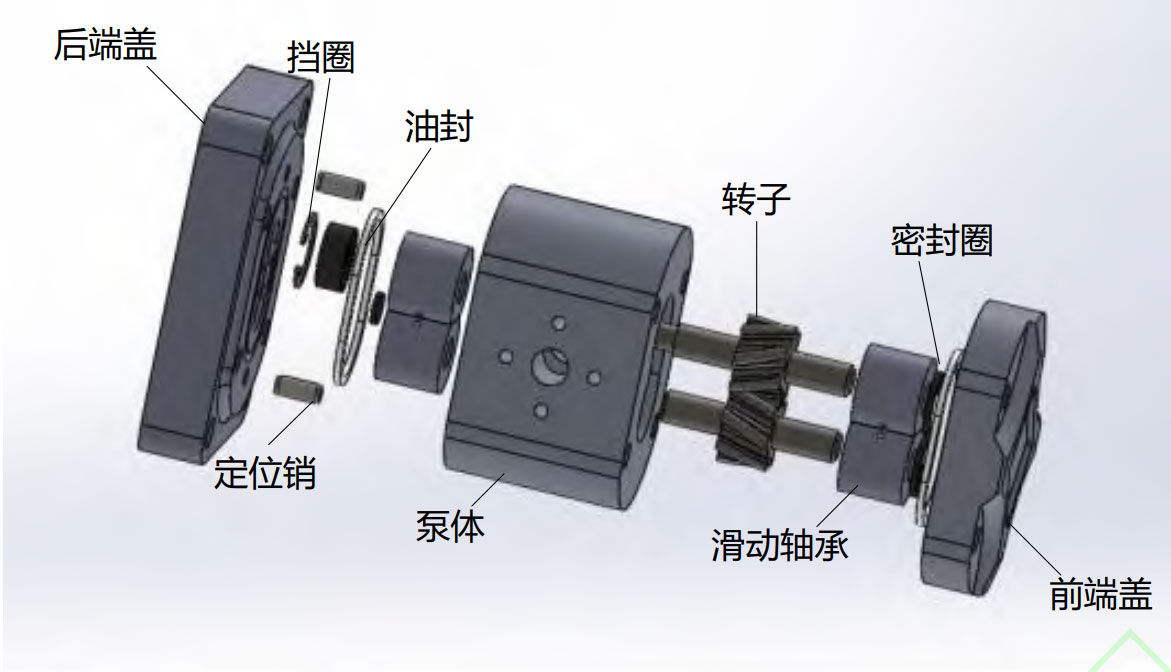

The rotor of the double arc helical gear pump adopts a double arc gear with a sine transition curve as the motion pair, and the point continuous contact is the rotor meshing method. Due to the fact that the end face overlap is less than 1 and the axial overlap is greater than 1 during the rotor meshing process, the gear pump has advantages such as no oil trapping, long service life, and good mechanical characteristics. In theory, this type of pump has good flow continuity, small pulsation, and further reduces noise, which can be called a “super silent” gear pump. The composition and structure of the double arc helical gear pump are shown in the figure.

The rotating pair formed by the meshing of the double arc helical gear rotor is the research object, and the model parameters of the double arc helical gear are shown in the table.

| Name | Symbol | Driving wheel rotor | Driven wheel rotor |

| Number of teeth | z | 7 | 7 |

| Pressure angle | α | 14.5° | 14.5° |

| End face modulus | m | 3 | 3 |

| Tooth width | b | 15.5mm | 15.5mm |

| Pitch diameter | D | 21mm | 21mm |

| Tooth tip circle diameter | Da | 25.3596mm | 25.3596mm |

| Root circle diameter | Db | 16.6404mm | 16.6404mm |

| Tooth tip arc radius | r1 | 2.1798mm | 2.1798mm |

| Overlap coefficient | ξ | 1.5 | 1.5 |

| Helix angle | β0 | 31.3° | -31.3° |