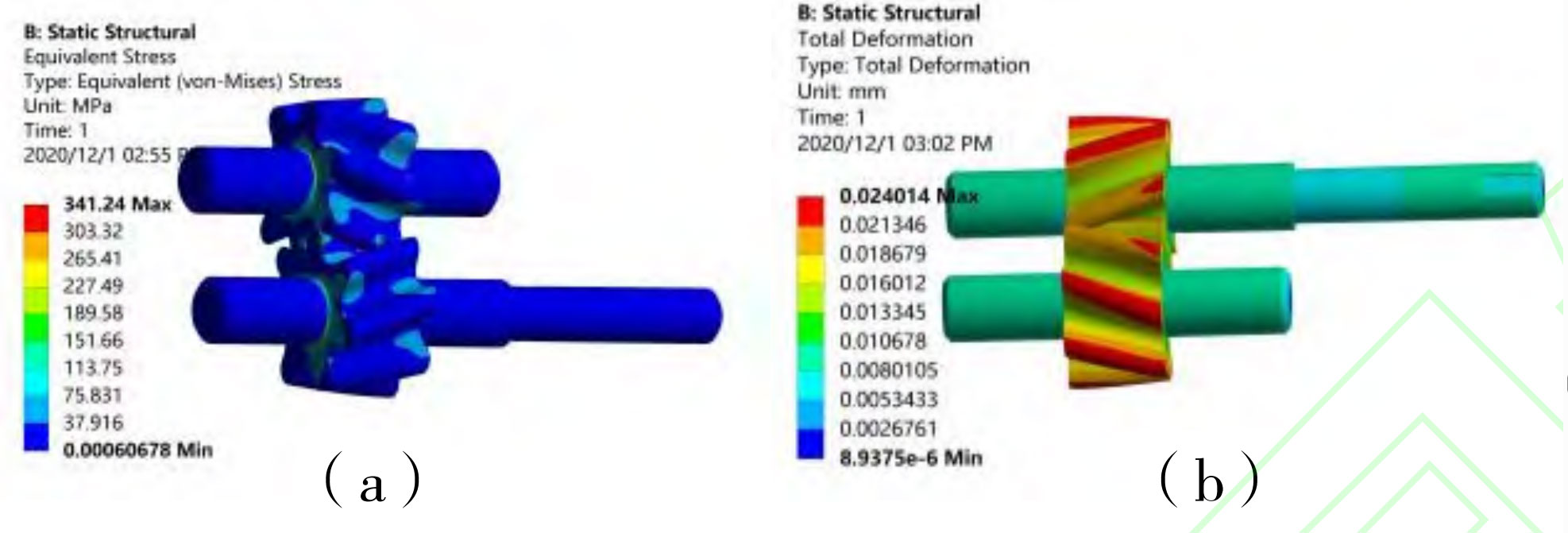

High speed and high pressure gear pumps are generally used in aerospace and require extreme weight. For the consideration of material reduction, lightweight, and performance improvement, the structure optimization of the double arc helical gear pump rotor in the lightweight direction was carried out. The optimized shaft has a major diameter of 8mm and a minor diameter of 7mm, resulting in a 28.32% reduction in shaft mass. Through ANSYS simulation analysis, when the outlet pressure of the rotor is set to 25MPa, the equal stress and maximum displacement deformation of the rotating pair are shown in the figure.

(b) Curve of maximum deformation change of rotating pair

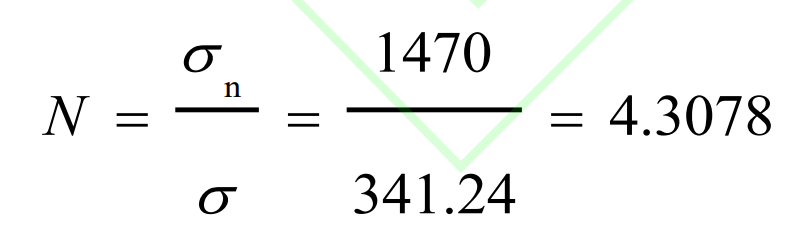

By comparing and analyzing the calculation results of the two designs, it can be seen that the maximum deformation position and stress concentration position are basically the same. The maximum deformation of the rotor is about 0.024014mm, and the maximum stress is about 341.24MPa. The maximum displacement deformation and maximum equivalent stress are reduced compared to before optimization. The expression for the safety factor at maximum equivalent stress is:

The safety factor of the optimized rotor has been improved to meet the usage requirements.