Compared with straight cylindrical gears, helical gears have the advantages of good meshing performance, large overlap, and compact structure, and are widely used in industrial equipment transmission devices. In the process of designing helical gear pair parameters, the conventional design concept is only to meet the working strength of the gear, while ignoring the strength difference problem between the large and small gears, causing premature failure of a certain gear and increasing the economic cost of maintenance. Therefore, in the process of helical gear parameter design, the strength difference problem between the large and small gears cannot be ignored. The research on optimization design of helical gears is as follows.

Luo Dengfeng et al. studied the influence of modification coefficient and helix angle on the strength of helical gears at the same center distance, providing a reference for the design of helical gears.

Zhao Ning et al. optimized the geometric parameters of cylindrical gear transmission using a fast non dominated genetic algorithm with elite strategy, with the objective functions of equal bending strength, high fit, and minimum volume. The Pareto optimal solution set was obtained, and an optimization scheme was selected to compare with the initial design scheme. The results showed that the strength of cylindrical gears with high fit was significantly improved.

Zhao Xiangfei and others comprehensively optimized the tooth profile parameters with the goal of minimizing the maximum bending stress during the transmission process to prevent bending and fracture of the gear pair. They used the APDL language of ANSYS software to conduct finite element modeling of the gear, and analyzed the bending stress in the meshing state. The reliability of the optimization results was verified, which has guiding significance for reducing the bending stress of the gear.

Zhou Libin and others conducted multi-objective optimization design on helical gears to improve their load-bearing capacity, and the results showed that their strength and stability reliability were improved.

Yang Hongbo et al. aimed to maximize the total overlap of helical gear pairs, minimize the fluctuation of transmission error, and minimize the total volume of gear pairs. After optimization, the fluctuation of meshing transmission error and system transmission error of the helical gear system were reduced to varying degrees.

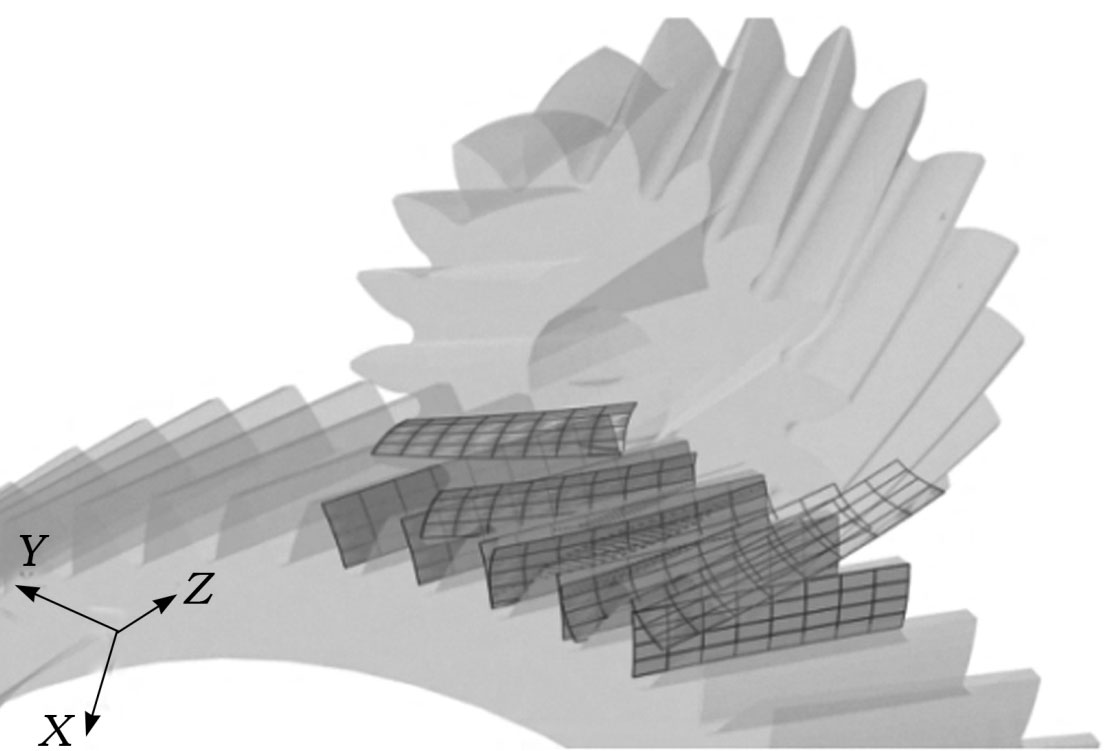

However, the design of helical gears must take into account the bending strength of the tooth root and the load-bearing capacity of the tooth surface, to prevent tooth root fracture and tooth surface pitting during the meshing transmission process, in order to achieve the optimal working performance of the helical gear pair. Therefore, the helical gear in the reducer is taken as the research object. In order to make the bending strength of the helical gear pair tooth root equal and improve the bearing capacity of the tooth surface, the minimum difference of the maximum bending stress of the helical gear pair tooth root and the minimum contact stress of the tooth surface are taken as the optimization objectives. The multi-objective particle swarm optimization algorithm is used to optimize the design, and the simulation verification is carried out through the MASTA software, so as to improve the overall service life of the helical gear pair.