To perform multi-objective optimization simulation verification of geometric parameters for helical gear transmission, it is essential to follow a systematic approach that includes the use of simulation software, evaluation of results, and comparison with theoretical predictions.

Here’s a step-by-step process for the simulation verification:

- Choose an appropriate simulation software: Select a suitable gear design and analysis software, such as KISSsoft, RomaxDesigner, or LDP/SimulationX, that supports multi-objective optimization and has the capability to handle helical gear systems.

- Input the design parameters: Define the initial geometric parameters for the helical gear system, such as the module, pressure angle, helix angle, face width, and number of teeth. Also, input the material properties, load conditions, and constraints applicable to your specific application.

- Set the optimization objectives: Specify the objectives you want to optimize, such as minimizing transmission error, maximizing load-carrying capacity, maximizing efficiency, minimizing size and weight, or minimizing manufacturing costs.

- Perform the optimization: Use the multi-objective optimization algorithm available in the software (e.g., NSGA-II, MOPSO, or MOEA) to find the optimal set of geometric parameters that satisfy the objectives while respecting the constraints.

- Analyze the results: Examine the results generated by the optimization algorithm to identify the trade-offs between the objectives. Use Pareto front analysis to visualize the relationship between the competing objectives, which can help you choose the best solution based on your specific application requirements.

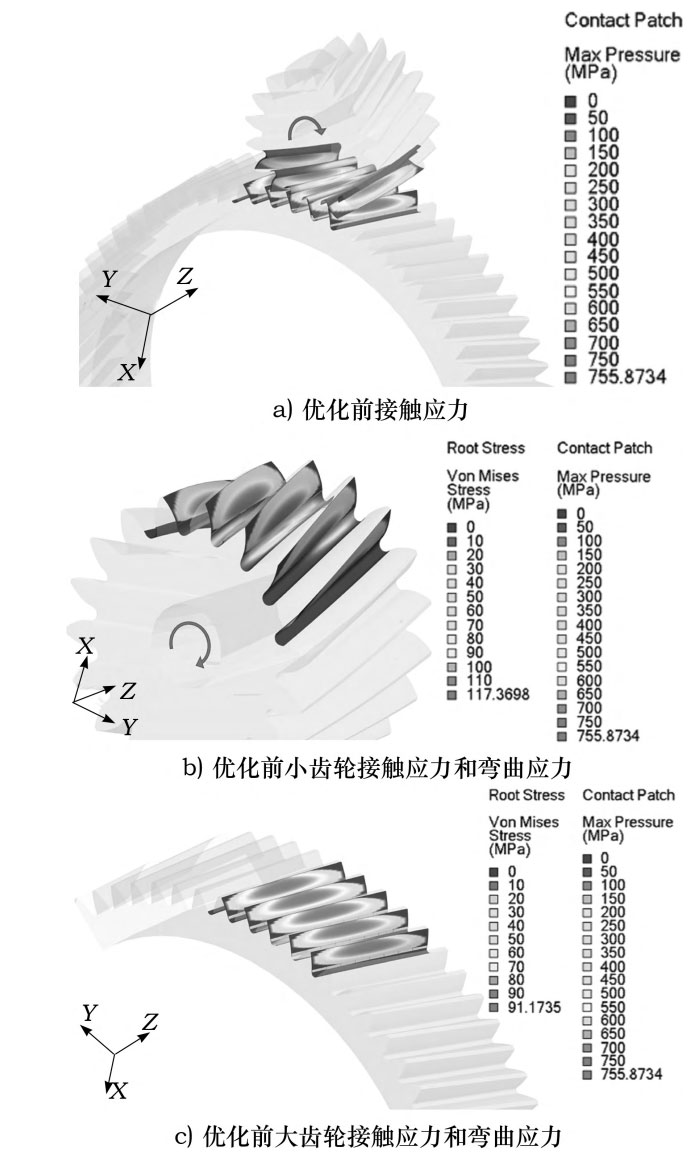

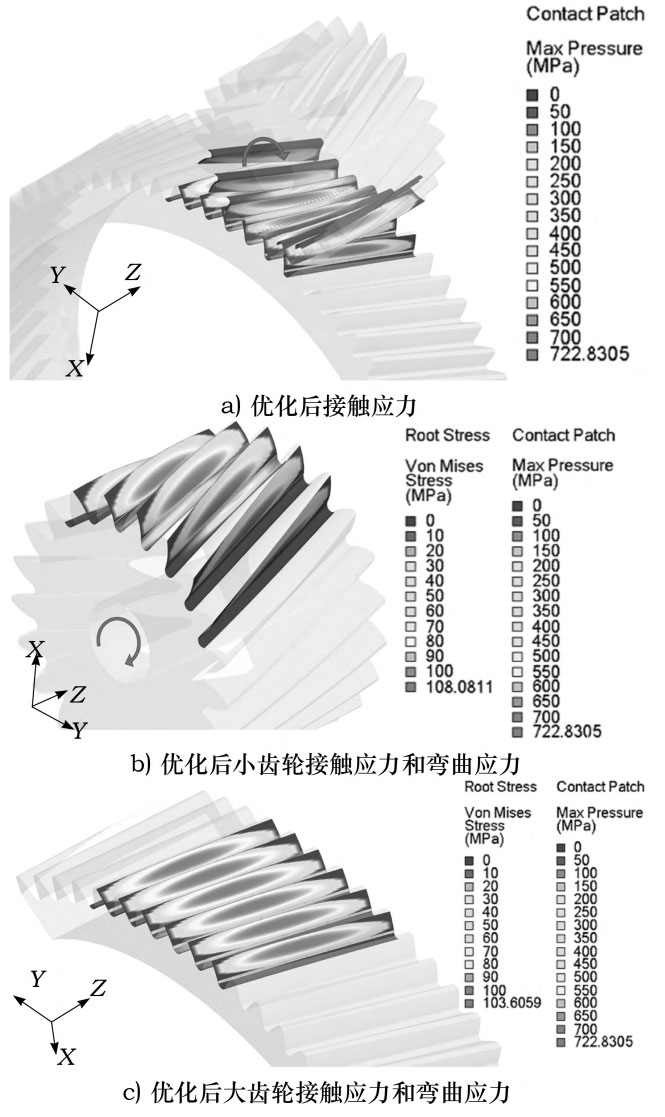

- Validate the optimized design: Perform additional simulation tests, such as stress analysis, contact analysis, or dynamic analysis, to validate the optimized design’s performance. Ensure that the optimized design meets the desired performance criteria and adheres to the constraints defined earlier.

- Compare with theoretical predictions: Compare the simulation results with theoretical predictions obtained from analytical models or experimental data to ensure the accuracy and reliability of the optimization process.

- Iterate if necessary: If the simulation verification results indicate that further improvements can be made, refine the optimization objectives, constraints, or initial design parameters, and repeat the optimization process.

By following this process, you can effectively perform multi-objective optimization simulation verification of geometric parameters for helical gear transmission. This approach will help you to achieve a more efficient, reliable, and cost-effective gear system that satisfies the desired performance criteria.