Gear forging is a manufacturing process that pushes the limits of gear performance by producing gears with exceptional strength, durability, and performance capabilities. Here’s how gear forging achieves this:

- Superior Strength: Gear forging creates gears with superior strength due to the grain flow and metallurgical structure of the forged material. The process involves subjecting the material to high pressure, which rearranges the metal’s internal structure and aligns the grains along the shape of the gear. This directional grain flow enhances the gear’s strength, toughness, and resistance to fatigue, allowing it to handle high loads and withstand demanding operating conditions.

- Enhanced Durability: Gears produced through forging exhibit enhanced durability and resistance to wear and fatigue. The uniform grain structure obtained during forging reduces the presence of internal defects and weak points, resulting in gears that can endure continuous and repetitive loading without failure. This durability is particularly crucial in industries such as automotive, aerospace, and heavy machinery, where gears are subjected to extreme conditions and prolonged use.

- Increased Load-Carrying Capacity: Gear forging enables the production of gears with increased load-carrying capacity. The superior strength and toughness achieved through forging allow gears to transmit higher torque and handle heavier loads. This capability is essential in applications that require high power transmission, such as wind turbines, heavy machinery, and industrial gearboxes.

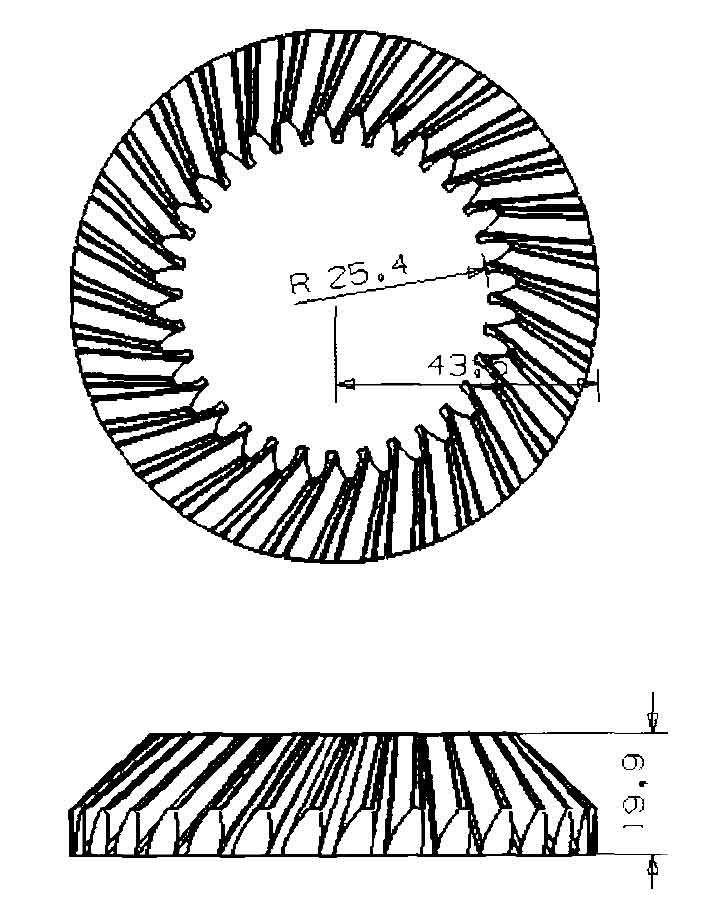

- Optimal Gear Tooth Geometry: Gear forging allows for the precise shaping of gear tooth profiles, ensuring optimal gear meshing and minimizing tooth deflection and misalignment. The near-net shape capability of forging reduces the need for extensive machining, resulting in accurate and consistent tooth profiles. This precise geometry improves the gear’s performance, efficiency, and noise characteristics.

- Enhanced Fatigue Resistance: Gears produced by forging exhibit excellent fatigue resistance, enabling them to withstand cyclic loading and extended service life. The forging process eliminates or minimizes internal defects and stress concentrations, which are common causes of fatigue failure in gears. The improved fatigue resistance of forged gears ensures reliable and long-lasting performance, even in high-cycle or high-stress applications.

- Customization for Specific Applications: Gear forging allows for customization to meet specific application requirements. The process accommodates a wide range of gear sizes, shapes, and materials, enabling the production of gears tailored to the needs of different industries and applications. Customization ensures that gears are optimized for specific operating conditions, including factors such as torque, speed, temperature, and environmental factors, pushing the limits of gear performance in diverse applications.

- Innovation in Materials and Processes: Gear forging drives innovation in materials and processes to further enhance gear performance. Advanced alloys and material compositions are developed to improve gear strength, durability, and resistance to wear and corrosion. Innovations in forging techniques, such as isothermal forging, precision forging, and microstructure control, allow for the production of gears with even greater performance capabilities. These advancements continually push the limits of gear performance in terms of load capacity, efficiency, and reliability.

Gear forging, with its ability to produce gears with superior strength, durability, and performance, is instrumental in pushing the boundaries of gear technology. By continuously exploring new materials, optimizing processes, and customizing gears for specific applications, gear forging enables the development of high-performance gears that meet the increasing demands of various industries and drive innovation in gear design and manufacturing.