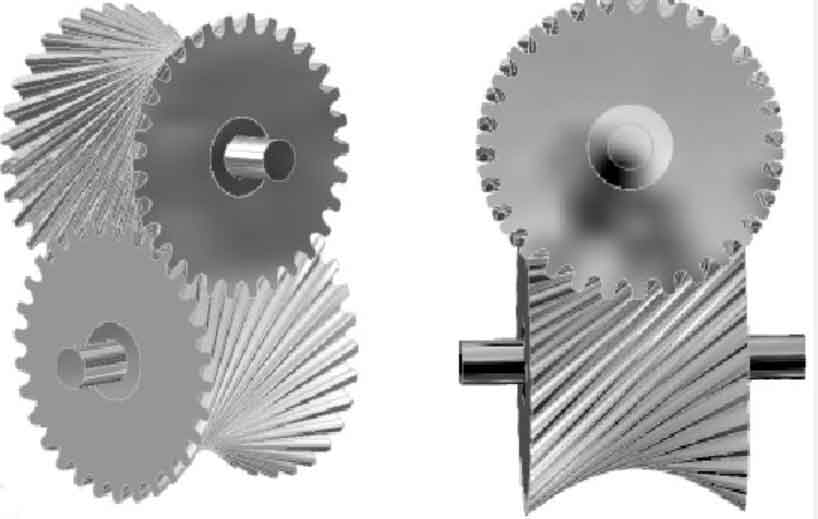

Hyperboloidal gears are a type of gearing system that feature curved teeth with a hyperbolic profile instead of the traditional involute profile found in most gears. This unique tooth profile allows for increased contact area and improved load distribution, resulting in higher torque capacity, smoother operation, and reduced wear.

Design of Hyperboloidal Gears: Hyperboloidal gears have teeth that are shaped like a hyperboloid of revolution. The tooth profile is generated by the intersection of the hyperboloid surface and the gear blank. The tooth shape is typically defined by a mathematical equation that describes the hyperbolic curve.

The design process involves determining the gear parameters such as the module (size of the gear teeth), pressure angle, helix angle, and the number of teeth. These parameters are crucial in ensuring proper meshing and transmission characteristics. Advanced computer-aided design (CAD) software is often used to model and generate the tooth profile accurately.

Applications of Hyperboloidal Gears:

- High-Performance Gearboxes: Hyperboloidal gears are commonly used in high-performance gearboxes found in various industries such as aerospace, automotive, and industrial machinery. Their enhanced load capacity and improved contact area make them suitable for transmitting high torque and handling heavy loads.

- Robotics and Automation: Hyperboloidal gears find applications in robotics and automation systems where precision, efficiency, and reliability are critical. They can be used in robot joints, robotic arms, and other motion control mechanisms to ensure smooth and accurate motion.

- Marine Propulsion Systems: Hyperboloidal gears are also used in marine propulsion systems, including ship engines and thrusters. The high torque capacity and improved load distribution make them well-suited for transmitting power in demanding marine environments.

- Wind Turbines: Hyperboloidal gears have been explored for use in wind turbines to enhance their efficiency and reliability. By improving load distribution and reducing gear wear, they can contribute to increased power generation and longer gear life in wind turbine systems.

- Medical Equipment: Hyperboloidal gears find applications in medical equipment such as surgical robots, diagnostic machines, and prosthetics. These gears can provide precise and reliable motion control in critical medical procedures and devices.

Benefits of Hyperboloidal Gears:

- Increased torque capacity: The hyperboloidal tooth profile allows for a larger contact area, enabling the transmission of higher torque loads.

- Improved load distribution: The curved tooth profile distributes the load more evenly across the gear teeth, reducing stress concentration and wear.

- Smooth and quiet operation: The improved contact area and optimized tooth shape result in reduced vibrations and noise during gear operation.

- Higher efficiency: The enhanced load distribution and reduced friction contribute to improved gear efficiency and power transmission.

- Extended gear life: The improved load distribution and reduced wear make hyperboloidal gears more durable and long-lasting.

In summary, hyperboloidal gears offer significant advantages over traditional gears, including higher torque capacity, improved load distribution, smoother operation, and increased durability. Their applications span a wide range of industries, including automotive, aerospace, robotics, and marine systems, where precision, reliability, and high-performance gear transmission are essential.