Gear hobbing is indeed a key manufacturing process used in the production of reliable and high-performance gears. It is a popular method for cutting teeth into gears and is widely utilized in various industries, including automotive, aerospace, and machinery.

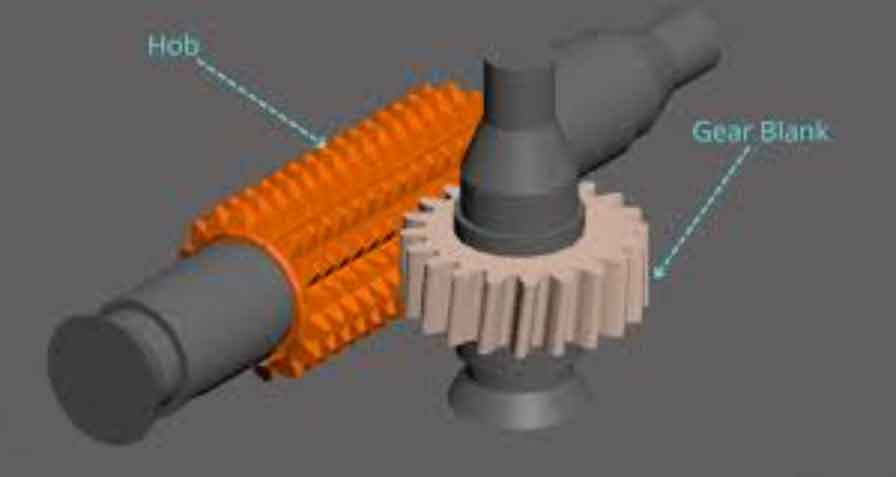

Gear hobbing involves using a specialized cutting tool called a hob to create gear teeth. The hob has a series of cutting edges that progressively remove material from the workpiece, forming the gear teeth in a precise and accurate manner. The process typically takes place on a gear hobbing machine, which rotates the workpiece and feeds the hob across it to generate the desired gear profile.

Here are some reasons why gear hobbing is considered advantageous:

- Precision and Accuracy: Gear hobbing allows for the production of gears with high precision and accuracy. The cutting process creates uniform teeth profiles, ensuring smooth and efficient gear operation. This precision is vital for applications that require reliable and consistent gear performance.

- Versatility: Gear hobbing can produce a wide range of gear types, including spur gears, helical gears, worm gears, and more. This versatility makes it suitable for various gear applications, whether it’s transmitting power, changing speed, or controlling torque.

- Efficiency: Gear hobbing is a relatively efficient process compared to other gear manufacturing methods. It can produce multiple gear teeth in a single pass, reducing production time and costs. Additionally, modern gear hobbing machines often incorporate advanced automation features, further enhancing efficiency.

- Strength and Durability: Gears manufactured through hobbing exhibit excellent strength and durability. The cutting process generates a continuous grain flow along the gear teeth, resulting in superior mechanical properties. This ensures that the gears can withstand high loads, transmit power efficiently, and have a longer service life.

- Cost-Effectiveness: Gear hobbing offers a cost-effective solution for producing gears in medium to high volumes. Once the hob is set up, it can produce gears at a relatively fast rate, making it suitable for mass production scenarios. Additionally, the long tool life of hobs helps to reduce tooling costs over time.

However, it’s worth noting that gear hobbing does have some limitations. It may not be suitable for very small or large gears, as extreme sizes may require alternative manufacturing methods. Additionally, gear hobbing involves the generation of cutting forces, which can cause tool wear and require regular maintenance and tool replacements.

Gear hobbing plays a crucial role in the production of reliable and high-performance gears. Its precision, versatility, efficiency, strength, and cost-effectiveness make it a preferred choice for many gear manufacturing applications.