Using a gear calculator can significantly streamline the gear design process and help optimize the performance of gear systems. Here are some tips and tricks to make the most out of a gear calculator:

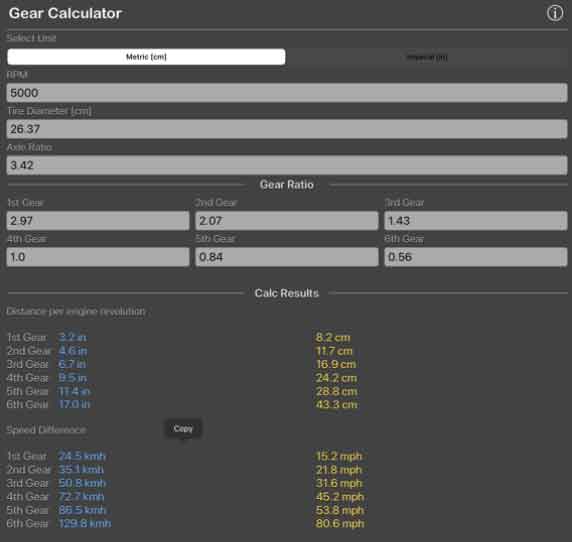

- Understand the Gear Calculator’s Inputs and Outputs: Familiarize yourself with the inputs required by the gear calculator, such as gear type, module or diametral pitch, number of teeth, and center distance. Additionally, understand the outputs provided by the calculator, such as gear dimensions, tooth profiles, contact ratios, and load capacities. Understanding the inputs and outputs will ensure you use the calculator effectively.

- Verify and Cross-Check Results: Although gear calculators provide convenient calculations, it’s crucial to verify the results and cross-check them using manual calculations or additional design references. This helps ensure accuracy and reliability in the gear design process. Comparing the calculator’s results with manual calculations also helps in gaining a deeper understanding of the underlying principles and equations involved.

- Explore Different Gear Configurations: Gear calculators often support various gear configurations, including spur gears, helical gears, bevel gears, and worm gears. Experiment with different configurations using the gear calculator to compare their performance characteristics, such as efficiency, load capacity, and noise levels. This will help you choose the most suitable gear configuration for your specific application.

- Optimize Gear Parameters: Utilize the gear calculator to optimize gear parameters such as the number of teeth, module or diametral pitch, and pressure angle. By adjusting these parameters, you can achieve the desired gear ratio, minimize noise and vibration, improve load distribution, and optimize the gear system’s overall performance.

- Consider Design Constraints and Standards: Gear design often involves specific design constraints and industry standards. Ensure that the gear calculator you are using accommodates these constraints and adheres to relevant standards. For example, if designing gears for automotive applications, consider standards such as AGMA (American Gear Manufacturers Association) or ISO (International Organization for Standardization) to ensure compatibility and reliability.

- Perform Sensitivity Analysis: A gear calculator can help you conduct sensitivity analysis by varying different parameters and observing the corresponding changes in gear performance. This allows you to evaluate the impact of different design choices and make informed decisions to optimize gear performance and meet design requirements.

- Leverage Additional Features: Gear calculators often offer additional features such as load distribution analysis, tooth contact analysis, and stress calculations. Explore these features to gain further insights into gear behavior and make more informed design decisions. These features can provide valuable information about potential areas of concern, allowing you to refine your design for better performance and reliability.

- Keep Abreast of Updates and Enhancements: Gear calculators may receive updates and enhancements over time. Stay informed about new releases or updates to ensure you are using the latest version with improved functionalities and enhanced accuracy.

Remember, while a gear calculator is a valuable tool, it is important to have a solid understanding of gear design principles and engineering fundamentals. The gear calculator is a facilitator that aids in calculations and simulations, but it should be used in conjunction with engineering knowledge and experience to ensure optimal gear design and performance.