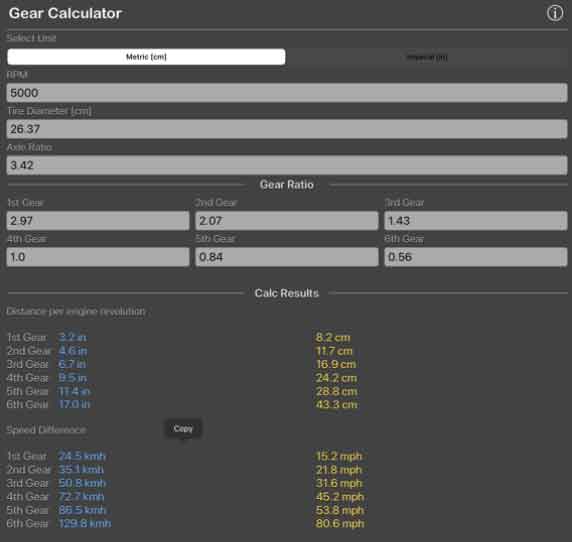

The gear calculator is an invaluable tool for precise gear ratio calculation in gear systems. It enables you to determine the required gear ratio to achieve specific speed or torque requirements. Here’s how you can use a gear calculator for accurate gear ratio calculation:

- Identify Input and Output Parameters: Start by identifying the input and output parameters of your gear system. These include the input speed (N1), output speed (N2), input torque (T1), or output torque (T2), depending on your specific application requirements. It’s important to have a clear understanding of the desired speed or torque values for accurate gear ratio calculation.

- Select Gear Type and Configuration: Choose the appropriate gear type and configuration for your application. Gear types can include spur gears, helical gears, bevel gears, or worm gears. Determine whether you have a simple gear pair or a more complex configuration such as a planetary gear system. The gear calculator should have options to accommodate your chosen gear type and configuration.

- Input Gear Data: Enter the available gear data into the gear calculator. This includes the number of teeth (Z1 and Z2) for both the driving and driven gears. Ensure that you enter the correct values for accurate calculations. The gear calculator may provide options to input additional parameters such as the module (m) or diametral pitch (P), pressure angle (α), or helix angle (β) for helical gears.

- Perform Gear Ratio Calculation: Once the necessary data is entered, the gear calculator will perform the gear ratio calculation based on the given inputs. It will use the formula:Gear Ratio = (Z2 / Z1) = (N2 / N1) = (T2 / T1)The gear calculator will provide the resulting gear ratio based on the entered parameters.

- Evaluate the Results: Review the calculated gear ratio and assess whether it meets your desired speed or torque requirements. If the calculated gear ratio matches your target, you can proceed with the selected gear configuration. If it doesn’t meet your requirements, you may need to adjust the gear parameters, such as the number of teeth or gear sizes, to achieve the desired gear ratio.

- Iterative Approach: Gear ratio calculation may require an iterative approach, especially when working with complex gear systems or planetary arrangements. In such cases, you may need to calculate the gear ratio for each stage of the gear system and combine them to obtain the overall gear ratio. The gear calculator can help streamline this process and provide accurate results.

- Consider Constraints and Practical Limitations: While calculating the gear ratio, it’s important to consider any constraints or limitations imposed by the gear system, such as the availability of standard gear sizes or practical limitations on gear dimensions. The gear calculator can assist in exploring different gear combinations that satisfy these constraints while achieving the desired gear ratio.

The gear calculator simplifies the gear ratio calculation process by performing the necessary mathematical calculations based on the provided inputs. It saves time and reduces the chances of errors associated with manual calculations. By utilizing a gear calculator, you can precisely determine the gear ratio required for your gear system, enabling you to design and optimize your gears for optimal performance.