If you’re new to gear design, using a gear calculator can greatly simplify the process and help you understand the fundamentals. Here’s a practical introduction to using a gear calculator for gear design:

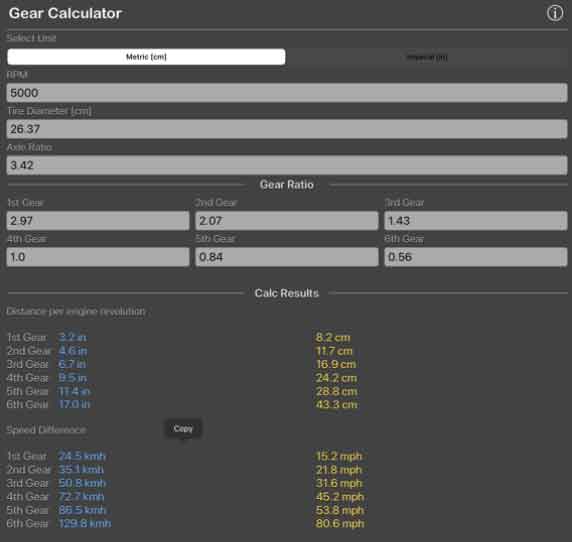

- Choose a Gear Calculator: Start by selecting a reliable gear calculator tool. There are various gear calculator software applications and online calculators available. Look for one that suits your needs, is user-friendly, and provides the necessary calculations for your gear design project.

- Input Basic Parameters: Begin by inputting the basic parameters required for gear design. These typically include the gear module (pitch), pressure angle, number of teeth, and gear type (spur, helical, bevel, etc.). These parameters define the geometry and characteristics of the gear.

- Calculate Gear Dimensions: Once the basic parameters are entered, the gear calculator will calculate the essential dimensions of the gear. These dimensions include the pitch diameter, addendum, dedendum, tooth thickness, and center distance (for multiple gears). These values determine the physical size and shape of the gear.

- Analyze Gear Ratios: Gear ratios are a critical aspect of gear design. The gear calculator allows you to calculate gear ratios based on the number of teeth on the driving and driven gears. You can experiment with different gear ratios to achieve the desired speed reduction or speed increase in your gear system.

- Evaluate Tooth Profiles: The gear calculator provides information about the tooth profiles based on the input parameters. It generates the shape and profile of the gear teeth, such as the involute profile for spur gears or helical profiles for helical gears. You can visualize the tooth profiles and assess their suitability for your application.

- Check Load Distribution: Load distribution analysis is essential to ensure proper load sharing between gear teeth. The gear calculator allows you to evaluate load distribution by providing contact ratios, contact patterns, and contact stresses. This analysis helps you optimize the gear design and ensure even load distribution for improved performance and durability.

- Optimize Efficiency: Gear calculators often provide efficiency estimation based on factors such as tooth profile, friction, lubrication conditions, and mechanical losses. Use this information to assess the efficiency of your gear design and identify areas for improvement. Adjust gear parameters and evaluate the impact on efficiency to optimize your gear system’s performance.

- Visualize and Validate: Many gear calculators offer visualization capabilities that allow you to see a 3D representation of the gear and its meshing behavior. Use this visualization to validate your design and verify that the gears mesh correctly and the tooth profiles are suitable for your application.

- Iterative Design Improvement: Gear design is an iterative process. Use the gear calculator to make adjustments to the parameters, such as the number of teeth, pressure angle, or gear ratios, and observe the resulting changes in dimensions, load distribution, and efficiency. Iterate on the design until you achieve the desired performance and characteristics.

- Refer to Design Guidelines: While using a gear calculator, it’s beneficial to refer to gear design guidelines or standards to ensure that your design meets industry best practices. These guidelines provide additional information and considerations for optimizing gear performance, such as backlash, tooth proportions, and material selection.

By following these steps and leveraging a gear calculator, you can gain practical insights into gear design and develop a solid foundation in gear engineering. The calculator simplifies complex calculations, provides visualization, and assists in making informed decisions to create effective gear designs. As you gain experience, you can explore more advanced features and delve deeper into gear design principles.