Chapter 1: Gear Hobbing Method

Brief overview of two methods of gear hobbing technology: gear hob hobbing and gear roller hobbing. Let me provide you with a bit more detail about each of these methods:

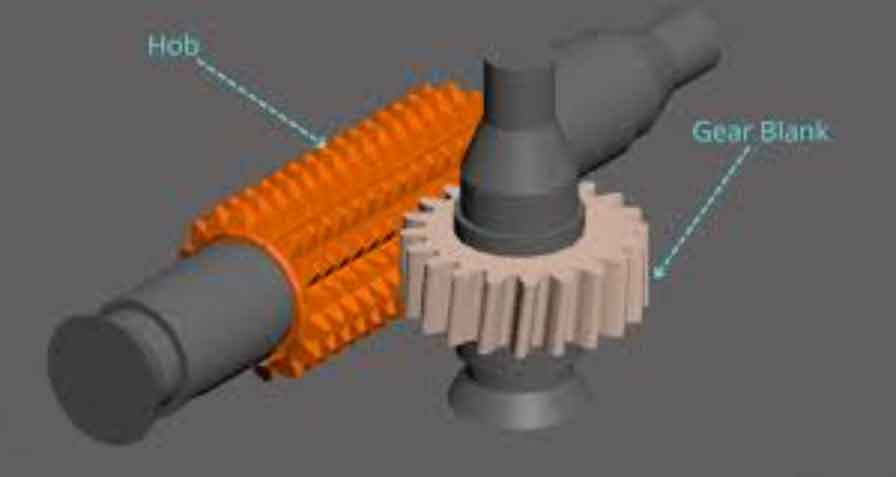

- Gear Hob Hobbing: Gear hobbing is a machining process used to produce gears. In this method, a specialized cutting tool known as a hob is used to create the gear teeth. The hob has a series of equally spaced cutting edges that gradually shape the gear tooth profile. The gear blank, which is the workpiece that will become the gear, is rotated while the hob is fed into it. As the hob cuts into the gear blank, it creates the gear teeth with the desired profile. This process is widely used for producing a variety of gear types, including spur gears, helical gears, and worm gears.

- Gear Roller Hobbing: Gear roller hobbing is another method used to manufacture gears. In this process, rollers with specific tooth profiles are employed to form the gear teeth through a rolling motion. The gear blank is placed between two of these rollers, and as the rollers rotate, they gradually shape the gear teeth on the blank’s surface. Gear roller hobbing is particularly useful for producing high-quality gear teeth with excellent surface finish and dimensional accuracy. It is often chosen for applications where precision is crucial.

Both gear hob hobbing and gear roller hobbing have their own advantages and applications. Gear hob hobbing is versatile and suitable for various gear types, while gear roller hobbing offers enhanced precision and surface quality. The choice between these methods depends on factors such as the type of gear being produced, production volume, required accuracy, and available equipment.

It’s important to note that the terminology and specifics of these methods can sometimes vary based on industry practices and technological advancements. If you’re looking for specific information about gear manufacturing, I recommend consulting specialized manufacturing literature or experts in the field.

Chapter 2: The Advantages of Gear Hobbing

Some key advantages of gear hobbing accurately:

- High Precision: Gear hobbing is a highly accurate manufacturing method that produces gears with consistent tooth profiles. This precision is crucial for ensuring smooth and efficient gear operation, especially in applications where minimal tolerance deviations are critical.

- High Efficiency: The minimal material deformation during gear hobbing leads to less energy loss and greater efficiency in gear transmission. This is especially beneficial for applications where energy conservation is important, such as in automotive transmissions or industrial machinery.

- Long Service Life: The excellent surface finish achieved through gear hobbing results in reduced friction and wear during gear operation. Gears with lower friction tend to have longer lifespans, making them well-suited for applications requiring durability and extended service intervals.

- Low Noise: The smooth tooth contact surfaces produced by gear hobbing contribute to quieter gear operation. The reduced noise level is particularly advantageous in applications where noise reduction is a priority, such as in consumer appliances or precision machinery.

- Wide Applicability: Gear hobbing is a versatile process that can be used to manufacture various types of gears, including spur gears, helical gears, worm gears, and more. This adaptability makes it suitable for a wide range of industries and applications, from automotive and aerospace to manufacturing and robotics.

- Material Versatility: Gear hobbing can work with a variety of materials, including metals and some non-metals. This flexibility allows manufacturers to choose the best material for their specific application requirements, whether it’s strength, corrosion resistance, or other factors.

- Cost-Effectiveness: Despite its precision, gear hobbing can be a cost-effective production method for high-volume gear manufacturing. Once the setup is optimized, the process can produce gears with consistent quality at a relatively efficient pace.

- Automation Compatibility: Gear hobbing is amenable to automation, which can streamline the manufacturing process and reduce labor costs. This makes it well-suited for large-scale production and ensures consistent quality throughout the production run.

It’s worth noting that while gear hobbing offers these advantages, each manufacturing method has its own strengths and limitations. The choice of gear manufacturing technique depends on factors such as gear complexity, production volume, required precision, material selection, and cost considerations.

Chapter 3: The Process Steps of Gear Hobbing

The key process steps of gear hobbing quite accurately. Gear hobbing is a common method used for producing gears, especially for high-precision and high-volume production. Here’s a more detailed explanation of each step:

- Pre-treatment: This step involves preparing the workpiece before the hobbing process. Heat treatment is often performed to improve the material’s hardness and other mechanical properties. Tooth root trimming may be necessary to remove any excess material that could interfere with the hobbing process.

- Selection of Hobs or Rollers: Choosing the appropriate cutting tool, such as a hob or roller, is essential. The selection is based on the gear specifications required, such as module, number of teeth, pressure angle, and profile. Different hobs or rollers have specific tooth profiles that need to match the desired gear specifications.

- Clamping Fixation: The workpiece is securely clamped onto a fixture or chuck. This ensures that the workpiece remains stable during the hobbing operation, preventing any unwanted movement that could result in inaccuracies.

- Hobbing Operation: In this step, the chosen hob or roller is set up on a hobbing machine. The workpiece and the hob are rotated simultaneously at precise relative speeds. As the hob’s teeth come into contact with the workpiece, material is gradually removed from the workpiece’s tooth profile, shaping it to match the hob’s profile. This process is repeated for each tooth until the entire gear is machined.

- Surface Treatment: Depending on the application and desired finish, the gear may undergo additional processes like polishing, grinding, or other surface treatments. This step aims to improve the tooth surface quality, reduce surface roughness, and enhance the overall performance of the gear.

- Inspection: After the gear hobbing process is complete, the manufactured gears are thoroughly inspected. Various measurements are taken to assess factors such as the gear’s dimensional accuracy, tooth profile conformity, tooth surface finish, and other quality parameters. Any deviations from the required specifications are identified during this stage.

The accurate execution of each of these steps is crucial to producing gears that meet the required specifications and quality standards. Gear hobbing is widely used in industries where precise and consistent gear production is essential, such as automotive, aerospace, and industrial machinery manufacturing.

Chapter 4: The Material Selection for Gear Hobbing

Material selection is a critical aspect of gear hobbing technology, as it directly impacts the performance, durability, and efficiency of gears. Different application scenarios, load conditions, and operating environments necessitate the use of specific materials that exhibit desirable properties. Here’s a breakdown of some key factors to consider when selecting materials for gear hobbing:

- Load and Stress Conditions: The material’s strength is a crucial factor. Gears experience various levels of load and stress depending on the application, such as high torque, high-speed, or heavy-duty scenarios. Higher-strength materials like alloy steels are often preferred for such cases to withstand these loads without deformation.

- Toughness and Impact Resistance: Gears can encounter sudden shocks or impacts during operation. Materials with good toughness can absorb these impacts without fracturing. This property is particularly important for gears in machinery where sudden load changes are common.

- Wear Resistance: Gears are subject to continuous contact and sliding against each other. Wear resistance is essential to ensure that the gears maintain their profile and effectiveness over time. Carburized steels, for example, form a hardened surface layer that enhances wear resistance.

- Surface Finish: The material’s ability to retain a smooth surface finish is important, as a rough surface can lead to increased friction and wear. Proper surface finish contributes to efficient power transmission and reduced noise.

- Fatigue Resistance: Gears undergo cyclic loading, which can lead to fatigue failure over time. Materials with good fatigue resistance are capable of enduring repeated stress cycles without failure.

- Heat Treatment Compatibility: Many gears undergo heat treatment processes like carburizing, quenching, and tempering to enhance their mechanical properties. The material’s response to these heat treatment processes can greatly influence the final gear characteristics.

- Corrosion Resistance: If the gears are exposed to corrosive environments or moisture, selecting a material with good corrosion resistance is crucial to ensure the longevity of the gears.

- Cost and Availability: Material selection also needs to consider economic factors. Some advanced materials might offer excellent properties, but they might be expensive or difficult to source.

- Manufacturability: The material should be suitable for the manufacturing processes involved in gear hobbing, such as cutting, shaping, and heat treatment. Some materials can be more challenging to machine or require specialized equipment.

- Noise and Vibration: Material properties can impact the noise and vibration levels of the gears during operation. Certain materials might dampen vibrations or generate less noise, improving overall gear performance.

In practice, various materials can be used for gear hobbing, including high-strength alloy steels, carburized steels, powder metallurgy materials, and even non-metallic materials like plastics in specific applications. The choice of material depends on a holistic evaluation of all these factors to ensure that the resulting gears meet the desired performance requirements and operational conditions.

Chapter 5: Gear Hobbing Machinery

Gear hobbing machinery plays a crucial role in the manufacturing of gears, and its evolution has greatly contributed to the precision and efficiency of gear production. Gear hobbing is a machining process used to create gears, involving the use of a specialized cutting tool called a hob. The hob is rotated while being fed against the gear blank, which results in the creation of teeth on the gear.

The development of manufacturing technology, particularly the advancement of CNC (Computer Numerical Control) technology, has revolutionized gear hobbing machinery. Here are some key points about modern gear hobbing machinery:

- CNC Precision: High-precision CNC gear hobbing machines offer enhanced accuracy and repeatability. Computer-controlled movements and cutting enable the production of gears with tight tolerances and complex geometries.

- Complex Gears: Traditional gear hobbing was limited to relatively simple gear geometries. However, with the advent of advanced CNC systems, gear hobbing machinery can now produce more complex gear profiles, including helical gears, worm gears, and involute splines.

- Automation and Efficiency: CNC gear hobbing machines can be integrated into automated production lines, leading to improved efficiency and reduced human intervention. This integration allows for continuous and consistent gear production.

- Tooling and Software: Modern gear hobbing machinery is often equipped with sophisticated tooling systems and software interfaces. These features enable quick setup, efficient tool changes, and the ability to program and simulate gear cutting processes digitally before actual machining.

- Materials and Coatings: Advances in cutting tool materials and coatings have contributed to increased tool life and better surface finishes. This is essential for achieving high-precision gears consistently.

- Quality Control: CNC gear hobbing machines often come with in-process measurement and quality control systems. These systems can monitor and adjust machining parameters in real-time to ensure that the produced gears meet required specifications.

- Flexibility: CNC gear hobbing machinery can be programmed to produce various gear sizes and types, making them versatile for different production requirements.

- Industry Applications: Gear hobbing is used in various industries, including automotive, aerospace, industrial machinery, and more. The ability to create high-precision gears is crucial for the proper functioning of these industries’ products.

The development of high-precision CNC gear hobbing machinery has significantly impacted the manufacturing landscape by enabling the production of intricate and accurate gears. This, in turn, contributes to the overall performance and reliability of the machinery and equipment that rely on these gears.

Chapter 6: The Application of Gear Hobbing

Gear hobbing is a highly versatile and precise manufacturing process used in various industries, especially where high-quality gears are essential for efficient and reliable machinery. Here’s how gear hobbing is applied in some of the mentioned fields:

- Engineering Machinery: Gear hobbing plays a crucial role in the production of gears used in construction equipment, industrial machinery, and other engineering applications. The process ensures the accurate shaping of gear teeth, which is essential for the smooth operation and durability of machinery.

- Automobiles: The automotive industry heavily relies on gear hobbing to manufacture gears for transmissions, differentials, and steering systems. Gear hobbing technology helps ensure optimal power transmission, fuel efficiency, and minimal noise in vehicles.

- Wind Power Generation: In wind turbines, where large gears are used to convert the rotational motion of the blades into electricity, gear hobbing is vital. High-precision gear teeth are essential for transferring power efficiently from the rotor to the generator, and gear hobbing ensures that these gears are manufactured with the required precision and durability.

- Aerospace: In aerospace applications, where safety and precision are paramount, gear hobbing is used to produce gears for aircraft engines, landing gear systems, and other critical components. The high demands on reliability and performance make gear hobbing an ideal choice for producing gears that meet aerospace standards.

- High Transmission Efficiency: Gear hobbing helps achieve high transmission efficiency by ensuring accurate gear tooth profiles, reducing friction, and minimizing energy loss in the power transmission process. This is crucial for applications where efficiency is a top priority.

- Low Noise Levels: Properly hobbed gears have precise tooth engagement, resulting in reduced noise levels during operation. This is particularly important in industries such as automotive and consumer products, where noise reduction is a significant factor in user satisfaction.

- Long Lifespan: Gears manufactured through hobbing are more likely to have a longer lifespan due to the precision and quality of the manufacturing process. This is vital in applications where downtime and maintenance costs need to be minimized.

- Accuracy and Precision: Gear hobbing technology allows for the production of gears with high accuracy and precision, meeting tight tolerances required in modern machinery. This is crucial for achieving optimal performance and compatibility of gears within complex systems.

Gear hobbing technology’s ability to produce high-quality gears with precise tooth profiles, optimal contact patterns, and excellent durability makes it an indispensable process in various industries that rely on intricate mechanical systems.

Chapter 7: Quality Control of Gear Hobbing

Quality control is a critical aspect of gear hobbing to ensure that the produced gears meet the required specifications and performance standards. Let’s break down the different elements of quality control in gear hobbing:

- Pre-Treatment of Workpiece: The quality of the starting material is crucial. Any defects, inconsistencies, or improper heat treatment can negatively impact the final gear’s integrity. It’s important to inspect and verify the material’s composition and properties before starting the hobbing process.

- Stability during Gear Hobbing: Stable machine operation is essential to achieve consistent and accurate results. Vibration, chatter, or other instabilities during hobbing can lead to uneven tooth profiles and decreased gear quality. Proper machine maintenance, calibration, and use of suitable cutting parameters are necessary to maintain stability.

- Geometric Dimension and Shape Inspection: Gears have strict geometric tolerances and shape requirements. The profile, tooth spacing, tooth depth, helix angle, and other dimensions need to be within specified limits. This is typically achieved through various inspection methods, including coordinate measuring machines (CMMs), optical measurement systems, and gear inspection machines.

- High-Precision Testing Equipment: As you mentioned, using advanced and calibrated testing equipment is crucial. This equipment should be capable of measuring gear characteristics at a high level of precision. High-quality measuring instruments help ensure that the gear’s dimensions and profiles meet the desired standards.

- Inspection Methods: Different inspection methods are used to assess various aspects of gear quality. These methods include:

- CMMs: Coordinate measuring machines provide accurate 3D measurements of gear dimensions.

- Optical Measurement Systems: These systems use optical sensors and cameras to capture detailed images for dimensional analysis.

- Gear Inspection Machines: Specifically designed machines that analyze gear parameters, including tooth profile, pitch, and runout.

- Surface Finish Measurement: The roughness and surface finish of gear teeth can impact performance and durability. Instruments like profilometers measure these characteristics.

- Statistical Process Control (SPC): SPC involves monitoring and controlling the production process to maintain consistent quality. It involves collecting and analyzing data during production to identify any variations or trends that could lead to defects. This allows for real-time adjustments to prevent issues.

- Documentation and Traceability: Keeping comprehensive records of all gear hobbing processes, inspection results, and any deviations from specifications is essential. This documentation provides traceability and helps identify areas for improvement.

- Training and Skill: Skilled operators who understand the intricacies of gear hobbing and quality control are crucial. Training ensures that operators can identify potential issues and take appropriate corrective actions.

Successful gear hobbing relies on a combination of proper pre-treatment, stable machine operation, and meticulous quality control. This includes employing high-precision testing equipment, advanced inspection methods, and maintaining comprehensive documentation throughout the process.

Chapter 8: Future Development of Gear Hobbing

Some key points regarding the future development of gear hobbing technology. Let’s delve deeper into each of these aspects:

- Industrial Automation and Intelligent Manufacturing: As automation and intelligent manufacturing systems become more sophisticated, gear hobbing processes can benefit greatly. AI and machine learning can be employed to optimize cutting parameters, predict tool wear, and adjust cutting strategies in real-time. This can lead to increased precision, reduced downtime, and better overall process efficiency.

- AI-Assisted Process Optimization: AI can be used to analyze data from previous gear hobbing operations and suggest optimal cutting parameters for different materials and gear types. This can significantly reduce trial and error in setting up new jobs and improve overall productivity.

- Predictive Maintenance: By integrating sensors and AI algorithms, gear hobbing machines can predict when maintenance is required, preventing unexpected breakdowns and minimizing downtime.

- Quality Control: AI-powered vision systems can inspect gears during and after the hobbing process, identifying defects and ensuring consistent quality. This reduces the need for manual inspection and lowers the chances of faulty components entering the market.

- High-Speed and Efficient Gear Hobbing: The demand for high-speed production of gears will continue to push the boundaries of gear hobbing technology. Innovations in tool materials, coatings, and cooling techniques will contribute to faster cutting speeds and higher efficiency.

- Advanced Tooling Technologies: Future developments might include advanced hob designs that allow for more complex gear profiles, improved tool life, and reduced wear. Multi-functional tools that can perform multiple operations in a single pass could also become more prevalent.

- Digital Twin Technology: Creating digital twins of gear hobbing machines and processes can aid in simulation, optimization, and troubleshooting. This technology can help engineers visualize the entire process and identify potential bottlenecks or issues.

- Customization and Flexibility: With intelligent manufacturing, gear hobbing systems can become more adaptable to various production needs. Rapid reconfiguration for different gear types and sizes can be achieved through software controls and minimal mechanical adjustments.

- Energy Efficiency: As environmental concerns grow, future gear hobbing machines might focus on reducing energy consumption through innovative designs, materials, and improved cooling systems.

- Collaborative Robotics: Cobots (collaborative robots) can work alongside human operators in gear hobbing processes, enhancing efficiency and safety. They can handle repetitive tasks, leaving complex decision-making and adjustments to human experts.

- Integration in Supply Chain: With digital connectivity and Industry 4.0 concepts, gear hobbing processes can seamlessly integrate into wider supply chain systems, providing real-time updates on production progress, inventory levels, and demand fluctuations.

- Skill Set Evolution: As gear hobbing technology becomes more advanced, the workforce operating these machines will require a blend of traditional machining skills and digital literacy to manage AI-driven systems effectively.

The future of gear hobbing lies in the integration of advanced technologies to achieve more precise, efficient, and adaptable manufacturing processes. This can lead to improved product quality, reduced costs, and increased competitiveness in the global mark