Harmonic gear transmission is currently widely used in automatic control systems such as aerospace, robotics, CNC machine tools, light industry machinery, and food machinery. In harmonic gear transmission without flexible bearings, the surface of the cam wave generator is severely worn. The author proposes a new design of harmonic transmission wave generator without flexible bearings, and uses computational fluid dynamics to obtain that when the elliptical clearance ratio is 3, the elliptical sliding bearing has the best lubrication performance, On this basis, this article further studies the parameter design of the biomimetic wear reduction structure on the cam surface.

In recent decades, researchers have found that some animals and plants in nature can use their own non smooth surface microtextures to adapt to the complex and ever-changing living environment around them. With the deepening of bionics research, surface texture technology has been used to improve the frictional properties of material surfaces, and has been widely applied in fields such as bearings, cylinder liners piston rings, seals, mechanical hard drives, artificial joints, and road surfaces.

1. Analysis model

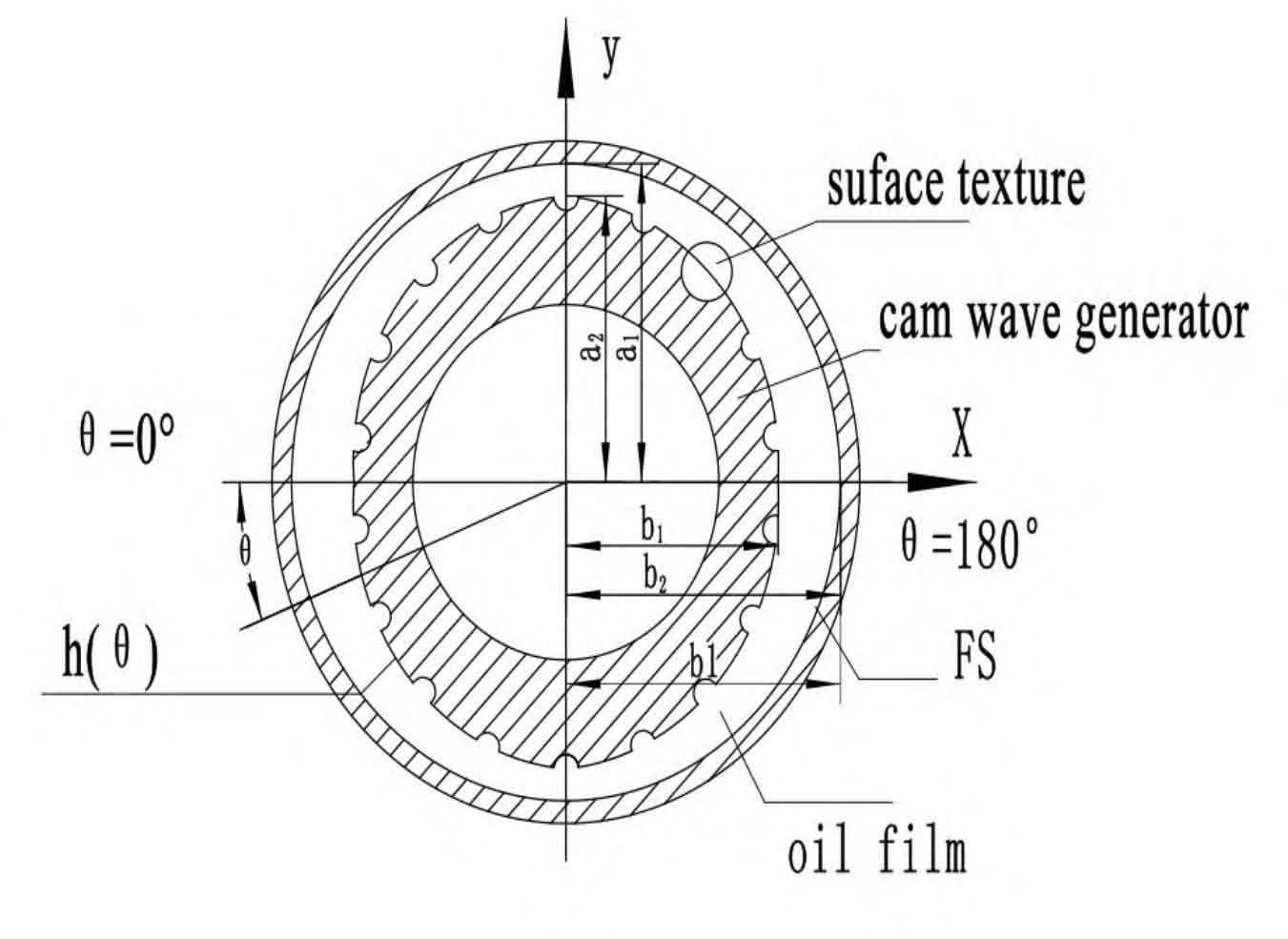

The fluid domain model between the cam wave generator and the flexible wheel is shown in Figure 1. The cam wave generator rotates counterclockwise at a speed n1, and the flexible wheel turns in the opposite direction to the cam wave generator. The outer wall of the cam wave generator and the inner wall of the flexible wheel are the boundaries of the oil film. Oil film thickness h( θ) From rotation angle θ= The maximum value hmax at position 0 has changed to θ= Min value hmin at 90 °. The width direction of the cam wave generator is the z-axis, and the outer surface of the cam wave generator is designed with a micro concave groove texture with a spherical cap shape at the bottom.

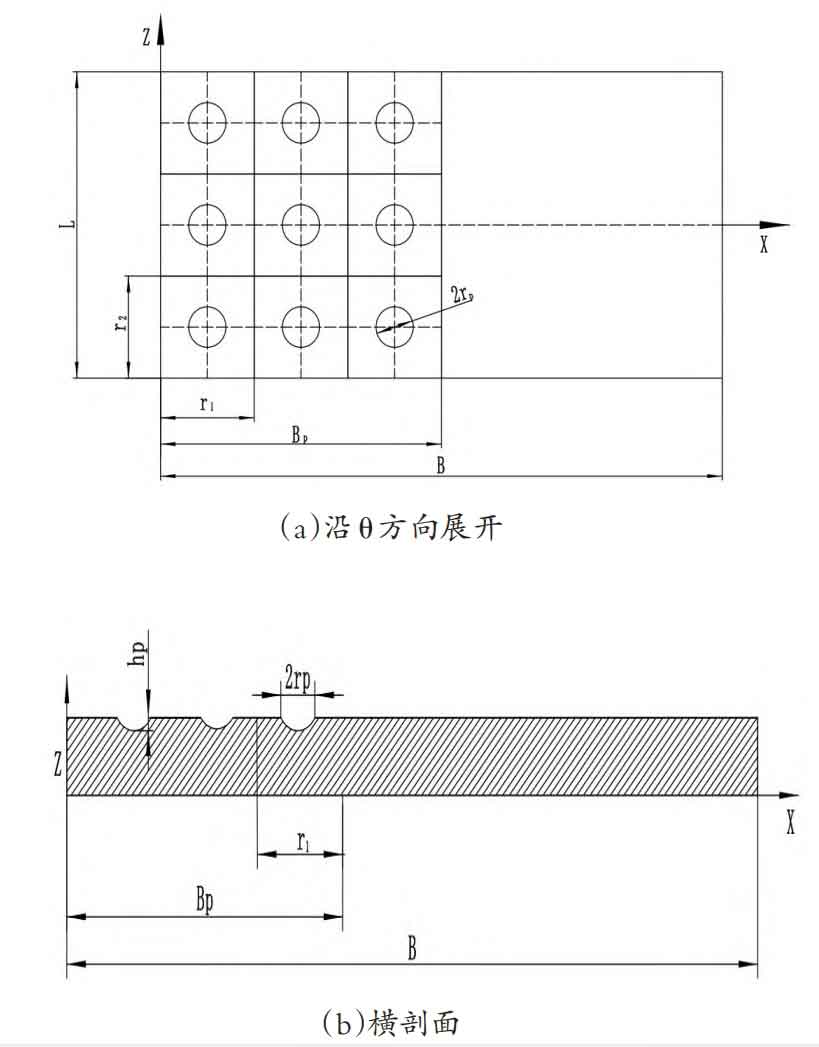

The design parameters of the concave texture include its distribution position, depth, shape, and density. Figure 2 shows the surface edge of the micro concave cam θ The unfolded diagram and cross-sectional diagram of the wave generator model along the x-axis. The parameters B and L are determined based on the elliptical gap between the cam wave generator and the flexible wheel. The ratio of Bp to B represents the distribution position of the surface texture of the cam wave generator’s concave pits, hp represents the depth of the concave pits, and the ratio of rp to hp represents the shape of the surface texture of the cam wave generator’s concave pits. The smaller the ratio of rp to hp, the smaller the curvature change of the concave pits; The ratio of parameter N π rp ^ 2/BL characterizes the density of micro pit textures on the surface of the cam wave generator.

2. Results and Analysis

2.1 The influence of texture distribution position

ZHYGear investigates the influence of three texture distribution positions on the lubrication characteristics of structural fluids. When the texture is uniformly distributed on the entire surface of the outer wall of the cam wave generator, it is called full area distribution; The texture distribution on the outer surface of the cam wave generator when the gap between the cam wave generator and the flexible wheel converges is called the convergence zone distribution; The texture distribution on the outer surface of the cam wave generator when the gap between the cam wave generator and the flexible wheel is divergent is called the divergent region distribution.

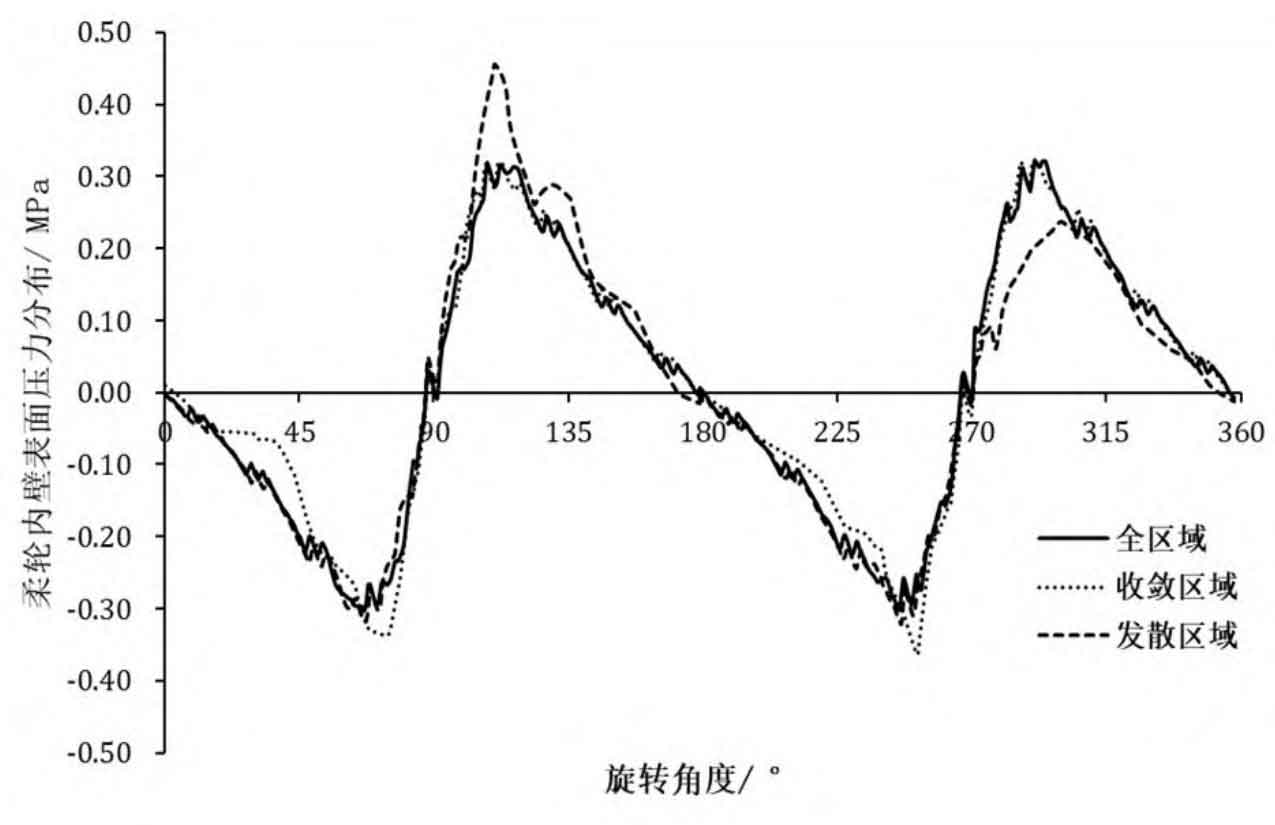

At z=0 δ= 3. Hmin=0.1mm ω= Under the condition of 2000rpm and hp=rp=1mm, the variation curve of the oil film pressure on the inner wall of the flexible wheel with the rotation angle of the cam wave generator at different micro groove texture distribution positions is shown in Figure 3. When the micro indentation texture is distributed in the divergent region, the pressure distribution of the oil film on the inner wall of the flexible wheel is smoother compared to when it is located in the convergence region; The pressure curve of the micro concave texture distribution in the convergence area of the cam wave generator is very close to the pressure curve of the full area texture distribution. The pressure curves of the two in the positive pressure zone of the oil film pressure almost overlap, but the distribution of the oil film pressure distribution curve in the positive and negative pressure zones under the full area texture distribution is more similar and symmetrical. At the same time, it can be seen that when the surface micro pits of the cam wave generator are distributed throughout the entire area, the oil film pressure curve has many small protrusions, which are located at the micro pit texture, characterizing the fluid dynamic pressure lubrication effect of the micro pit texture on the oil film pressure and bearing capacity.

The result analysis shows that the structural bearing capacity of the texture distribution in the convergence region is similar to that of the texture distribution in the entire region, but the structural friction force at this time is the highest among the three distribution positions, which is not conducive to improving the lubrication characteristics of the structure. The structural friction force when the texture is distributed in the divergent region and the structural friction force when the texture is distributed in the convergent region are similar, and the bearing capacity at this time is the highest compared to the other two situations. Therefore, the lubrication performance of the structure with micro pits and grooves distributed in the divergent region is superior to that distributed in the convergent region. However, when the texture is distributed in the divergent region, the friction force also increases while enhancing the structural bearing capacity, Compared to texture, its lubrication performance decreases across the entire surface area of the model.

2.2 The influence of texture depth

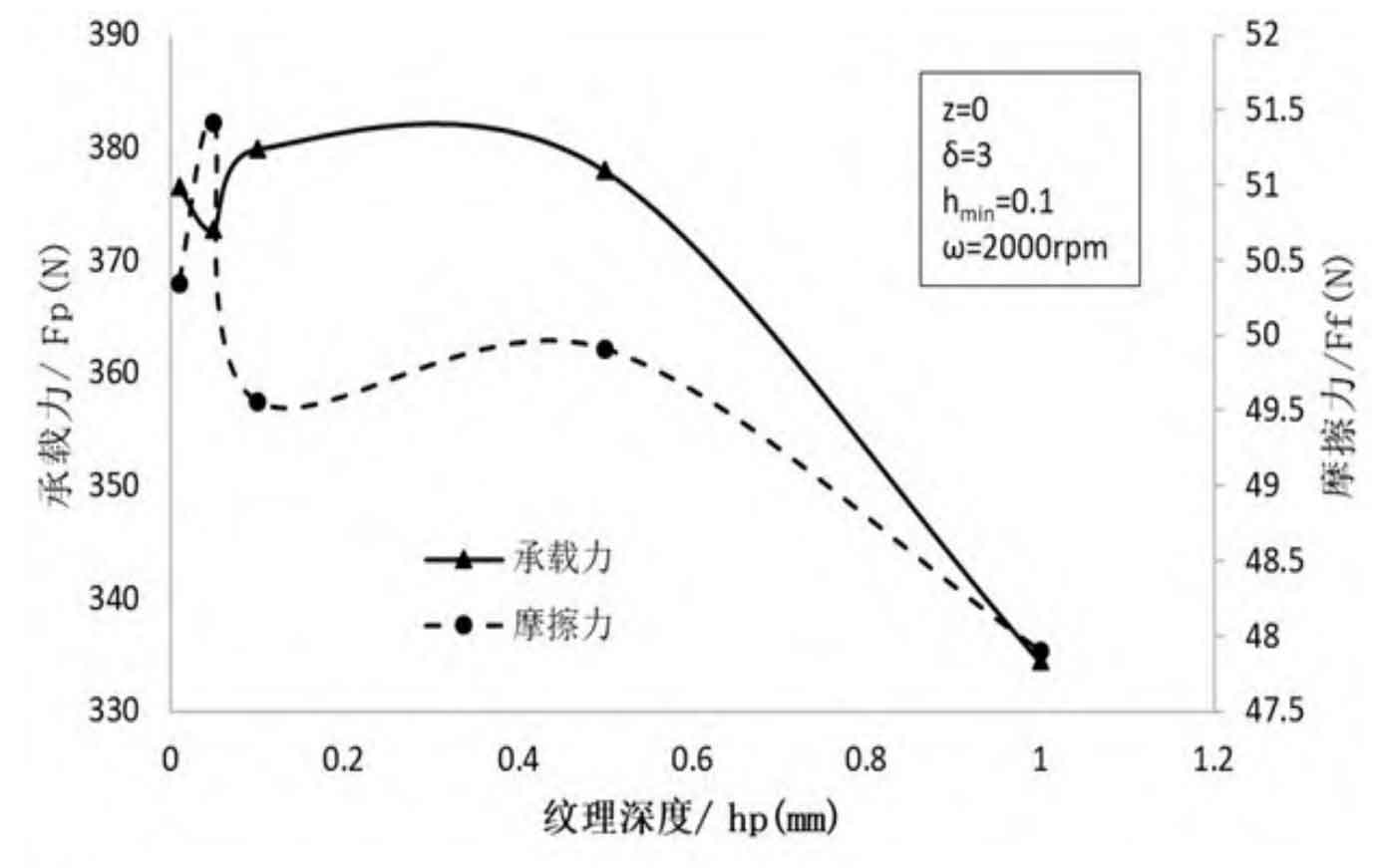

As shown in Figure 4, when the micro texture depth is 0.1mm, the maximum pressure of the oil film on the inner wall of the flexible wheel is the highest compared to the integral pressure of the oil film. This indicates that when the micro texture depth on the surface of the cam wave generator is 0.1mm, the lubrication performance and load-bearing performance of the structure are optimal. At this point, the load-bearing capacity of the structure is maximum, while the frictional force of the structure is minimum.

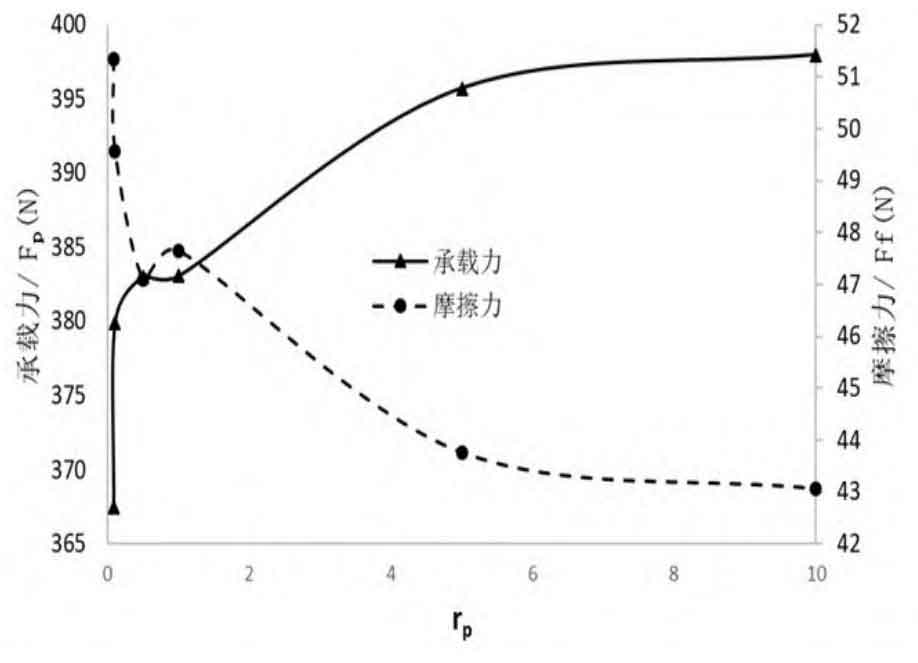

2.3 The influence of texture shape

ZHY Gear conducted simulation analysis on the pressure distribution, structural load-bearing capacity, and frictional force changes on the inner wall of flexible wheels under different pit shapes with micro pit textures. The ratio of parameters rp to hp can characterize the shape of the micro pit texture on the surface of the cam wave generator. The depth of the texture hp is 0.1mm, and the smaller the ratio of rp to hp, the smaller the change in pit curvature. The variation curve of structural bearing capacity and friction force with the surface micro indentation texture parameter rp of the cam wave generator is shown in Figure 5. When the value of parameter rp is greater than 6, the bearing capacity and friction force of the structure tend to stabilize and no longer increase with the increase of parameter rp. At this time, the local fluid dynamic pressure effect of the micro indentation texture on the surface of the cam wave generator tends to stabilize, and the flow state tends to stabilize, which can greatly improve the bearing capacity, Therefore, the parameter rp has an optimal value of 6.

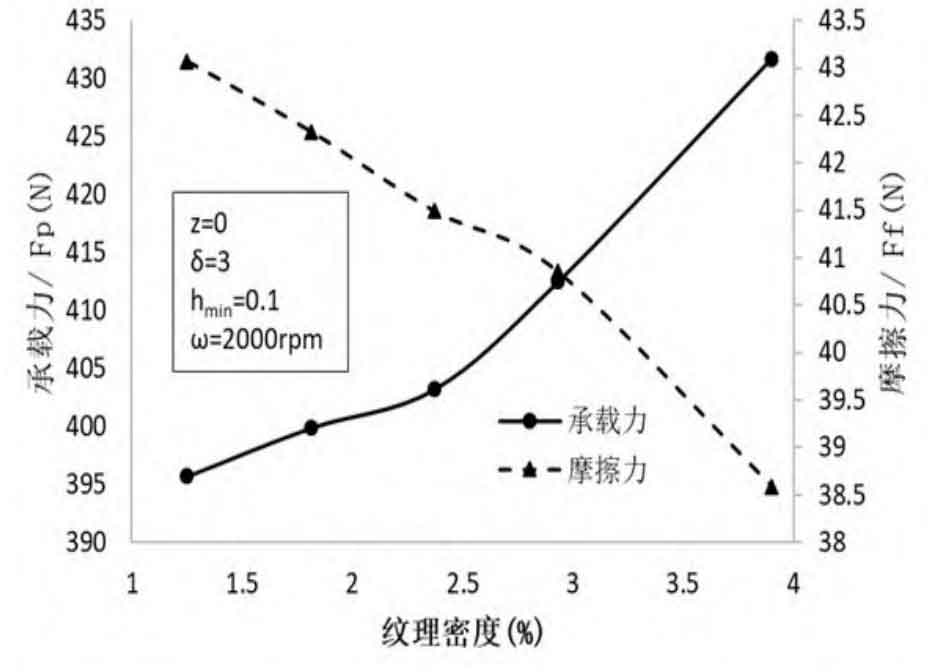

2.4 The impact of texture density

The density of micro groove textures on the surface of the cam wave generator can be characterized by the ratio of parameter N π rp ^ 2/BL, where N represents the number of micro groove textures, π rp ^ 2 represents the area of a single micro groove texture on the surface of the cam wave generator, BL represents the area of the cam wave generator unfolded along the x-axis, and the ratio N π rp ^ 2/BL represents the proportion of micro groove area on the surface of the cam wave generator. The larger the ratio, the greater the ratio, The higher the density of micro pits and textures on the surface of the cam wave generator. The variation curve of structural bearing capacity and friction force with the density of micro pits on the surface of the cam wave generator is shown in Figure 6. As the density of micro pits on the surface of the cam wave generator increases, the cumulative effect of local fluid dynamic pressure becomes stronger. Therefore, the load-bearing capacity of the structure is higher, the friction force is smaller, and the lubrication performance is better.

3. Conclusion

The simulation analysis of the influence of biomimetic micro concave structure parameters on the lubrication performance of harmonic gear transmission without flexible bearings on the cam surface shows that:

(1) When the micro indentation texture is distributed throughout the entire surface area of the cam wave generator, compared to the distribution in the convergence and divergence regions, the lubrication characteristics and load-bearing capacity of the structure are better.

(2) When the depth of micro indentation texture hp is greater than the gap scale of the structure, the load-bearing performance of the structure sharply decreases, and the deeper the depth, the worse the load-bearing performance of the structure. When the scale of micro indentation texture depth hp is similar to the structural gap scale, there exists an optimal value of 0.1mm for hp, at which point the structural bearing capacity is maximum and the structural friction force is minimum.

(3) The shape of micro pits is characterized by the ratio of rp to hp. The smaller the ratio, the smaller the curvature of the micro pits. For a given transmission, there is an optimal value of 6mm for rp.

(4) The higher the density of micro pits on the surface of the cam wave generator, the stronger the cumulative effect of local fluid dynamic pressure, the higher the load-bearing capacity of the structure, the smaller the friction force, and the better the lubrication performance.